3 key factors to select the right cables for outdoor projects

The common feature of outdoor projects is the harsh working environment, constantly under the influence of weather such as rain, heat, wind, UV rays, etc. Therefore, the selection of power cables for the environment is difficult and time-consuming. So how to choose the right power cable for an outdoor project? Please refer to 3 important factors below.

Today, to contribute to the success of the outdoor project, we should choose the right power cables and accessories. In some situations, if you choose cables that do not have appropriate features in an environment with extreme weather conditions, investors will spend a lot of money to repair, maintain and replace electrical cables in the future. This situation leads to affecting the efficiency of project results.

1. The basic structure of outdoor power cables

The electrical cables suitable for outdoor installation environments usually include two layers:

• Conductive core: The conductor core is usually copper or aluminum material, ensuring purity to meet a good level of electricity transmission.

• Insulating sheath & outer sheath: The insulating sheath & outer sheath act as protection and insulation to the conductor core.

At the same time, the insulation and outer sheath are made of materials that are resistant to the impact of the external environment. For example, PE or XLPE, and XLPO (cross-link).

2. Insulation and sheath of outdoor power cables

PE and XLPE are two common materials used in outdoor environments. Depending on the environment and the characteristics of the installation area, you can choose a cable with these two materials.

• PE (Polyethylene) material

PE is a thermoplastic, widely used thanks to its low cost. PE is a material with good weather resistance, so it is often used for outdoor electrical cable products. However, the temperature resistance of PE is lower than that of XLPE.

• XLPE material

XLPE stands for Cross-Linked Polyethylene, which is a material made up of different chains of polyethylene and tightly cross-linked with each other.

In this way, they prevent the polymer from separating or melting at high temperatures. Therefore, XLPE will be suitable for making electrical cable sheaths, protective sheaths for outdoor installation environments, and in places frequently exposed to high temperatures.

In addition, XLPE material also possesses the following advantages:

• Long life and durability

• No transfigure and melting in a high-temperature environment

• Good waterproof and water resistance

• Chemical resistance, no change, no corrosion when encountering chemicals

• Make sure not to contain Halogen gas – a substance that, when burned, will produce toxic gas, affecting human health. Because if you are exposed to halogen gas for a long time in a fire accident, you will easily sting your eyes, temporarily lose your ability to see, and even faint.

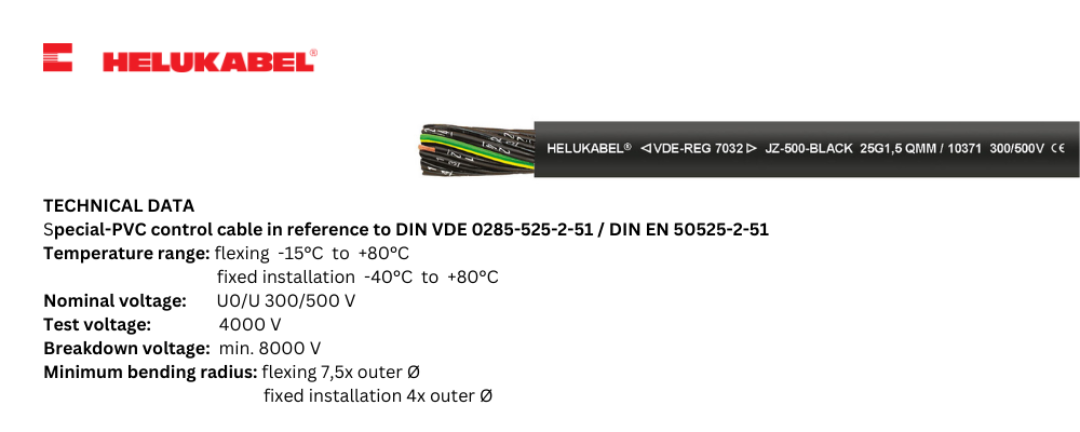

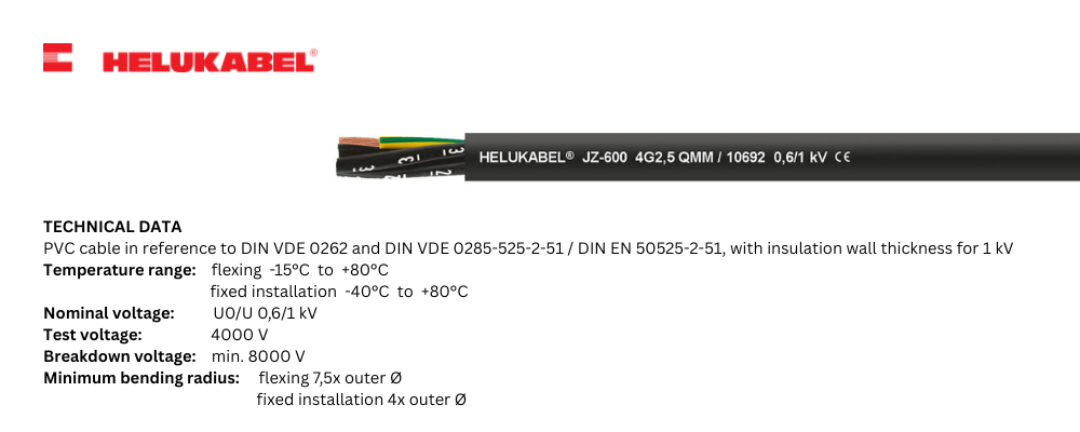

In addition to the above two shell materials, the control cable for outdoor use is also made of PVC compound, both saving costs and ensuring quality for the project. However, the PVC compound must be able to withstand outdoor weathering and UV rays.

Some control cables are good for outdoor conditions that you can refer to, such as JZ-500 black, JZ-600, and JZ-600-Y-CY.

OTHER POSTS >>> AUTOMATION IN ELECTRONIC COMPONENT MANUFACTURING

See more of our similar products on E-store HERE .

Technical documentation of the JZ-600 product HERE .

Technical documentation of the JZ-600-Y-CY product HERE .

3. Factors to keep in mind when choosing outdoor power cables

With the characteristics of harsh environments, to ensure that outdoor power cables meet installation standards and are safe to use, you need to pay attention to the following factors:

- Material

In particular, the insulation or outer sheath should be made of PE plastic or cross-linked compounds like XLPE, and XLPO materials.

- Application

Typical for solar project applications, XLPO is a commonly used material thanks to its outstanding properties, for instance being resistant to the impact of UV rays, and ozone, waterproof, fireproof, flame-retardant, fire-resistance, etc, or retrofit armor to resist rodent attack.

- Durability

For outdoor applications, the durability of power cables is expected over the life of the project (10 to 20 years). For instance, wind power projects, and solar power.

Thus, the selection of power cables for outdoor projects should consider the basic requirements of materials, applications, and product durability. Only by choosing the right product that meets the above requirements can you ensure a smooth project operation, limit unexpected problems, contribute to increased efficiency, and save time and costs for your business.

If you need more specific advice on electrical cables or accessories for outdoor projects or other industries. Please contact our engineers for advice and detailed solution support.

See more electrical cables for outdoor projects at our E-store on Tiki HERE .

OTHER POSTS >>> 3 APPLICATIONS OF TOPFLEX®-EMV-UV-3 PLUS 2YSLCYK-J CONTROL CABLE