Cables, Wires and Accessories for Lift, Crane & Hoist

Cranes and hoists play a vital role across many industries, enabling the lifting, lowering, and movement of heavy loads. They are used in various settings, such as rotating tower cranes at construction sites, bridge cranes in factories and warehouses, gantry cranes in shipyards and ports, slewing cranes in production lines, and hydraulic lifts or platforms for other specific tasks. Each of these applications comes with unique environmental challenges and technical requirements, particularly for the electrical systems involved.

One of the biggest demands on these systems is the ability to handle intense mechanical stress. Cables used in cranes must endure forces like pulling, compressing, abrasion, bending, and twisting. To ensure smooth and reliable operation, these cables need to be both sturdy and flexible. Cranes and hoists are often exposed to harsh weather conditions, including wind, rain, and extreme temperatures, so the cables must resist moisture, UV rays, and temperature fluctuations. Additionally, they frequently encounter oils and corrosive chemicals, meaning the cables must also be designed to withstand these substances effectively.

Crane cables are normally used to deliver power or control signals to equipment, which also covers many other applications with the same function that power and control cables are applied in cranes, hoists, and festoons. These mobile machines are dedicated to lifting and handling equipment and the cables applied therein require robust outer sheaths for protection against constant reeling and movement as well as resistance to oils, low temperatures and chemicals.

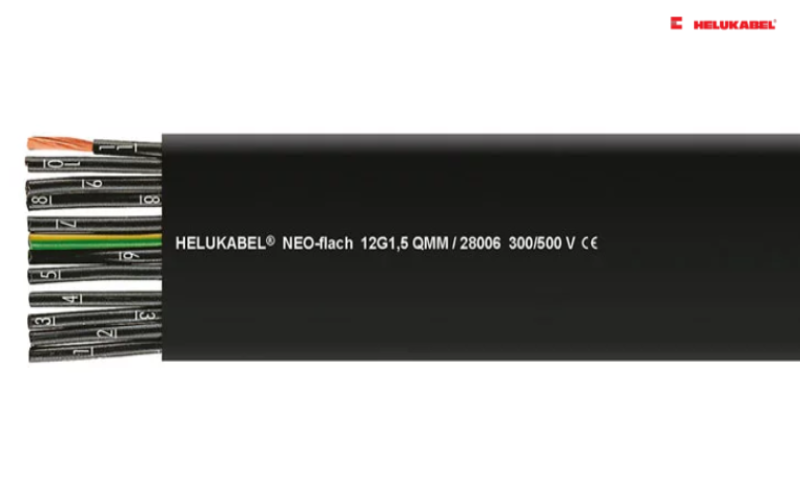

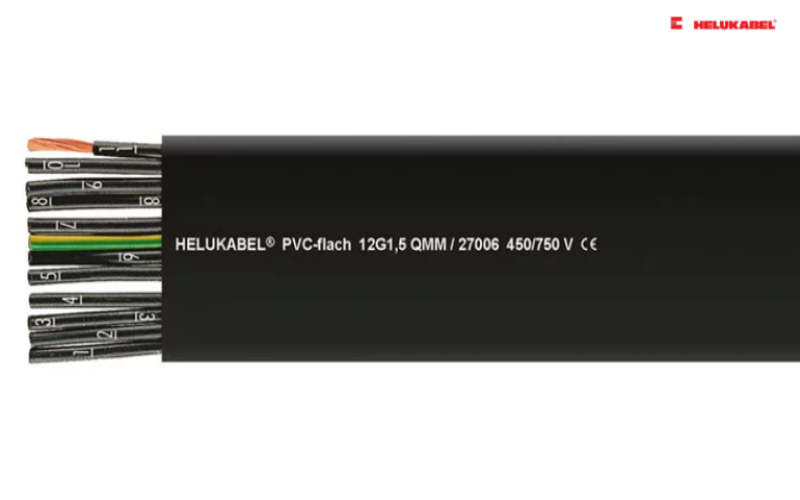

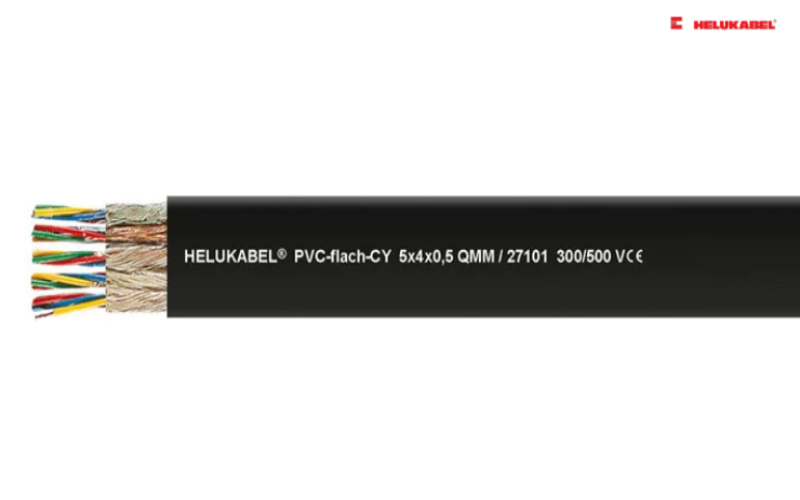

- For cranes used in horizontal application, the cables are usually Neoprene NEO-Flat, PVC sheathing (PVC-flat) with available shield or unshielded versions.

- Regarding hoists for vertical application, cables are often manufactured with Twist-protection and connected between motor and hand-help.

- Especially, crane cables can also be applied to festoons, conveyors and gantries.

In the industrial environment, the lift control cables are equipped with a suspension unit and serve the control panel of lift systems. For this reason, the obligatory technical requirements include high flexibility, extremely small bending radius, long service life and attainable elevated economic efficiency. The features of flame retardant and self-extinguishing are also required.

Cables used in crane makers, lifting and hoisting equipment require particularly high quality standards to ensure flawless operation at low temperatures and resistance to hydraulic oil leaks. At the same time, they should also be well designed to withstand rotating movements and to allow the integration of BUS components. At HELUKABEL, we offer a wide range of cables and accessories dedicated to Lift, Crane & Hoist.

Do you have any questions?

We look forward to assisting you in identifying the best products for your specific application and to answering any questions you might have. Please call

+84 28 77755578 or email us via

info@helukabel.com.vn