Temperature-resistant cables for the steel industry

1. What are temperature-resistant cables?

Temperature-resistant cables are specially designed for extreme temperature environments, whether very hot or very cold. These cables are ideal for applications requiring stable performance under such conditions, often found in industries like metallurgy, steel, cement, glass, and ceramics processing. Seasonal temperature changes can also affect the cable sheath when used outdoors, especially for cables in constant motion.

With global temperatures rising, selecting the right cable for each application is essential to reduce risk. Additionally, choosing a reputable manufacturer ensures high-quality temperature-resistant cables.

2. Features of temperature-resistant cables

Temperature-resistant cables feature specialized insulation and sheathing to withstand high temperatures without degradation. Key characteristics include:

- High temperature resistance: Designed to perform reliably in high temperatures, ideal for industries with continuous high-heat operations.

- Specialized material composition: Made from materials like silicone rubber, Teflon (PTFE), mica, fiberglass, and ceramics, each offering unique heat tolerance suited to specific environments.

- Exceptional durability: Resistant to oxidation and brittleness, extending lifespan and reducing replacement needs.

- Flexibility and ease of installation: Despite heat resistance, remains flexible, fitting into tight or complex spaces.

- Environmental resistance: Built to endure wear, seasonal temperature changes, and harsh conditions.

- Versatile applications: Suitable for diverse industries such as metallurgy, steel production, cement, glass, ceramics, refrigeration, and offshore applications.

These features make heat-resistant cables a robust solution for demanding, high-temperature applications.

3. The importance of temperature-resistant cables

3.1 Role of temperature-resistant cables in various industries

Heat-resistant cables play a crucial role in many industrial sectors, providing stability and safety for equipment exposed to high temperatures. Their ability to withstand substantial temperature fluctuations helps protect electrical systems from damage, maintaining long-term performance.

3.2 Temperature-resistant cables in the steel industry

Whether in construction, transport or for tools and machines - it is impossible to imagine the various branches of industry without steel and therefore, it is considered the most important metal of our time. The Federal Republic of Germany is the largest steel producer in the European Union and the Steel Industry is, for this reason, indispensable.

In blast furnaces, liquid pig iron is produced from ferrous input materials. It is then processed into crude steel in steel mills. The individual production processes involve extremely high temperatures and flying sparks, and aggressive substances are used. The cables and accessories used for production must be able to withstand these conditions.

In the steel industry, where extreme temperatures often surpass the safe limits of standard cables, heat-resistant cables are vital. Materials like silicone, mica, and Teflon enable these cables to resist oxidation and wear without degrading under high heat. Additionally, heat-resistant cables can endure mechanical impacts in continuous production lines. Choosing suitable heat-resistant cables ensures efficient operation of electrical and automation systems, reducing production downtime and enhancing worker safety.

But, in order for the required energy to reach the plants in the first place, the power supply around the site must also be established - strict requirements are also placed on these cables. Thus, depending on the application, cable types with special requirements for the insulation of the cores and the sheath are in demand. Whether control cables, data cables or cable glands - at HELUKABEL, we offers the right products for this special industrial environment. And for the cabling from the transformer stations to the factory premises, we also have the right types of underground and medium voltage cables in its broad product portfolio.

Do you have any questions?

We look forward to assisting you in identifying the best products for your specific application and to answering any questions you might have. Please call

+84 28 77755578 or email us via

info@helukabel.com.vn

CONTACT US VIA ZALO

4. HELUKABEL's temperature-resistant cables

HELUKABEL provides many types of temperature-resistant cables. Some of these include:

4.1 PVC and XLPO (Cross-Linked Polyolefin) temperature-resistant cables

PVC and XLPO cables are designed to withstand temperatures up to 145°C. Based on specific application needs, users can select additional features such as enhanced fire resistance or shielding capabilities. Options include control and connection cables like the HELUTHERM® 145 MULTI, HELUTHERM® 145 MULTI-C, and HELUTHERM® 120. Additionally, there are single-core options such as HELUTHERM® 145, HELUTHERM® 145 UL/CSA 600V, HELUPOWER® THERMFLEX® 145, and HELUPOWER® THERMFLEX® 145-C, each tailored to various high-temperature requirements

4.2 Silicone rubber temperature-resistant cables

Silicone rubber temperature-resistant cables can operate at temperatures up to 180°C, with both insulation and outer sheath made of specialized silicone rubber. The unique sheath enhances abrasion resistance and flexibility, extending product lifespan beyond standard silicone cables. These control cables are available in halogen-free versions and provide strong resistance to molecular oils, plasticizers, diluted acids, bases, and oxidizing agents.

At HELUKABEL, the THERMFLEX 180 EWKF cable is ideal for high-stress environments and is suitable for dry, damp, and outdoor conditions. It is widely used in HVAC, lighting, oven wiring, saunas, foundries, steelworks, cement plants, ceramics, and in heating and cooling systems.

4.3 Glass silk temperature-resistant cables

Glass silk temperature-resistant cables are designed with an outer layer made from fiberglass, allowing them to withstand higher temperatures than standard cables. Typical products, like HELUTHERM® 400, HELUTHERM® 400-MULTI, and HELUTHERM® 400-MULTI-ES, can resist temperatures around 400°C. For applications requiring even higher thermal resilience, HELUTHERM® 600 and HELUTHERM® 600-ES offer durability up to 700°C, making these cables ideal for extreme heat environments.

4.4 FEP temperature-resistant cables

This is a type of cables made drom FPE material, withstanding temperature up to 205°C. Typical products include: HELUFLON®-FEP-6Y , HELUFLON®-FEP-6Y MULTI.

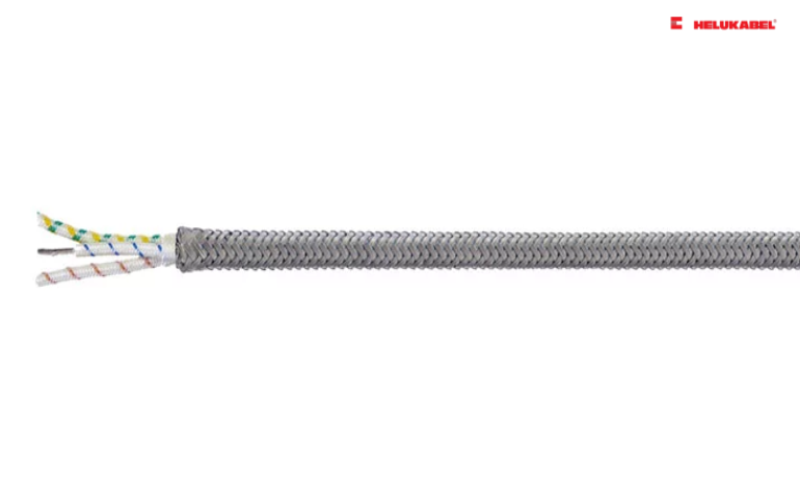

In the field of cable accessories, HELUKABEL offers heat-resistant cable protection conduit systems. For example, the HTP conduit for high temperature protection, which has a high insulation factor due to the silicone jacket containing iron oxide, can be used at 1,090°C for a short time. In addition, the HELU-S-RK-N cable lugs made of nickel can be used for temperatures up to +500°C, and the metal conduit with Agraff profile made of stainless steel can be used for temperatures up to +600°C.

HELUPOWER 1000-RV-K

Documents about HELUPOWER 1000-RV-K heat resistant cable