What are direct burial cables? Top 5 benefits of direct burial cables

What are the direct buried cables? What should be paid attention to when installing direct buried cable?

Today, in electrical projects, there are many ways of installing cables. For projects that require underground cable installation, it will bring many challenges for electrical engineers. Installation by this method requires experienced engineers to install the right technique and ensure safety during use.

1. What are direct burial cables?

Direct burial cables are a construction method that buries cables directly into the ground. This method is often used in the telecommunications industry, underground cable systems, and solar farms.

Direct burial cables have a special outer sheath, which is made from XLPE, and XLPO materials and can withstand the impact of external factors such as moisture, water, and pressure.

2. Methods of burying cables directly in the ground

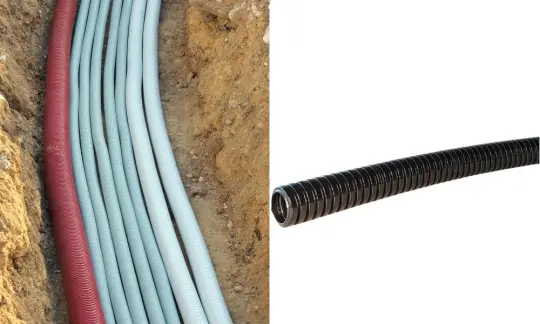

2.1. Using HDPE protective pipe

In construction sites with many obstacles and uneven installation terrain, HDPE pipes protect cables safely against obstacles and easily fold or bend on terrains.

Depending on the soil properties where you install cables, we will decide whether to install the cables in the HDPE pipe. Although using the protective pipes helps to limit the negative impact on the cable quality, when the transmission fails, repairing the protective tube will be time-consuming and difficult. If you want to repair and maintain cables, it will be difficult to pinpoint the problem because it is separated by an outer protective pipe.

2.2. Direct burial cables

Direct burial cables do not need to use protective pipes, the cables will be constructed and placed directly in the ground. For this construction method, the selected cables must be of good quality with the corresponding specifications in the operating environment to avoid causing bad situations such as short circuits, breaks, unstable transmission, etc.

At the same time, this installation method requires experience and a high level of expertise to ensure that the transmission is always stable, and the cables are not affected by environmental factors thanks to the calculation in the installation.

3. Top 5 benefits of using direct burial cables

3.1 Weather-resistant

Burying the cable directly in the ground will helps ensure the longevity of the wire against adverse effects caused by weather conditions such as hot sun, and UV rays.

3.2 Safety

Burying cables underground will also limits cable breaks that endanger people.

3.3 Easy to repair and maintain

Cables buried directly in the ground will be easily repaired when needed without the difficulties of using external protective pipes.

3.4 Cost saving

Cables buried directly in the ground without protective pipes will help save money on pipe costs, as well as save more time and effort in installation.

3.5 Ensure aesthetics

Burying cables directly in the ground will not expose too many conductors in the project, bringing high aesthetics.

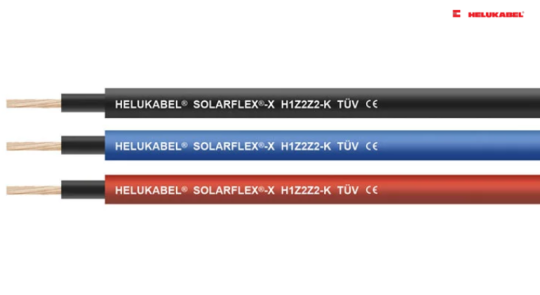

4. SOLARFLEX®-X H1Z2Z2-K – Direct burial cables

Among the electric cables used for construction directly buried in the ground, the SOLARFLEX®-X H1Z2Z2-K cables are a specialized DC cable product for photovoltaic systems, capable of being buried directly in the ground.

Outstanding features of SOLARFLEX®-X H1Z2Z2-K cables

- UV protection

- Weather resistant

- Halogen free, meets flame retardant standards

In particular, the AD8 water resistance standard and the ability to be buried directly in the ground have helped the SOLARFLEX®-X H1Z2Z2-K DC cables ensure a stable power transmission even when the soil environment is wet, even areas partially flooded without timely drainage due to heavy rain.

5. Top 2 important notes while installing direct burial cables

5.1 Installation environment

The environment will affects the cable selection. If the cables are installed in an area prone to local flooding or a humid area, you need to choose good waterproof cables according to the AD8 standard. If the cables are installed in an area prone to rodent attacks, you need to choose cables with a rodent-resistant sheath.

5.2 Soil properties

The type of soil can affect the installation of direct buried cable. In some areas, soil containing special substances will be more susceptible to corrosion of cable sheath, so you need to choose direct burial cables with protective sheaths to limit the corrosion of soil and related components mandarin.

Understanding the advantages and considering the factors that affect direct burial cable will help you ensure the safety and efficiency of your project. If you need more specific advice on solutions for each project, please contact our engineers for quick support.

>> Find out more: What type of cables and wires HELUKABEL are offering for our customers?

If you still have any concerns or questions, don't hesitate to reach out to HELUKABEL Vietnam's engineering team promptly for detailed assistance.

HELUKABEL® Vietnam

| Address | 905, Nguyen Kiem Street, Hanh Thong Ward, Ho Chi Minh City 700000, Vietnam |

| info@helukabel.com.vn | |

| Hotline | +84 28 77755578 |

| Website | www.helukabel.com.vn |

| Discover our products and place orders | Tiki | Shopee | Lazada | Product finder |

| Follow us on | Facebook | LinkedIn | Instagram | Youtube | Zalo | WhatsApp | Tiktok | Spotify |