What are plastic drag chains? Are they really good?

Nowadays, drag chains are one of the favorite products in industries, especially manufacturing plants. This device not only helps protect cables but also makes installation easier. In addition, drag chains also contribute to facilitating the repair or maintenance of electrical cable systems.

When the demand for drag chains is increasing, manufacturers launched many drag chain products made from distinctive materials such as plastic, iron, stainless steel, etc. Among the materials, plastic drag chains are considered a popular product because of their high applicability in many fields and help businesses optimize costs more than other materials.

>>See more: What are drag chains and whey are they used?

1. What are plastic drag chains?

Plastic drag chains are mechanical devices designed to protect and guide electrical cables, signal cables, or fluid hoses in systems with continuous movement. Made from engineered plastics such as glass-fiber-reinforced polyamide, cable carrier chains offer excellent strength, wear resistance, chemical resistance, and stable performance under extreme temperature conditions.

These products are widely used in industries such as automation, production lines, industrial robotics, and CNC equipment, thanks to their ability to minimize cable twisting, breakage, or damage during operation. Compared to steel cable carriers, plastic cable carriers have significant advantages, including lightweight construction, reduced noise levels, and lower installation costs.

2. Advantages of plastic drag chains

Plastic cable carrier chains, typically made from polyamide or combined with other materials such as aluminum, iron, or steel, are engineered to suit a wide range of applications and environmental conditions. Manufacturers can customize the design and materials to meet specific usage requirements.

Below are some key advantages of plastic cable carrier chains:

2.1 Superior wear and impact resistance

Plastic cable carrier chains are manufactured using high-quality materials with excellent wear and impact resistance. This ensures optimal protection for cables and hoses, particularly in systems with continuous motion or heavy mechanical loads. Their superior durability reduces the risk of damage, prolongs the product’s lifespan, and minimizes replacement and maintenance costs.

2.2 Reliable performance in harsh environments

Plastic cable carriers are highly resistant to challenging environmental factors such as acids, salts, or exposure to oils and grease. Thanks to their excellent chemical and corrosion resistance, they are ideal for use in industries such as food processing, chemical plants, or outdoor applications where high humidity or chemical exposure is common.

2.3 Temperature resistance from -20℃ to 100℃

With 35% glass-fiber-reinforced polyamide 6 as a primary material, plastic cable carriers can operate efficiently in a wide temperature range. This makes them suitable for environments with extremely low temperatures (e.g., cold storage facilities) or high temperatures (e.g., metallurgical production lines or thermal power plants).

2.4 Lightweight design for easy installation and maintenance

Compared to metal cable carriers, plastic cable carriers are significantly lighter, reducing the load on machinery. Their modular design allows for quick assembly and disassembly, making maintenance and repair simple and cost-effective.

2.5 High load-bearing capacity

Despite their lightweight construction, plastic cable carriers are designed to handle high pressure and heavy loads due to their robust structure and durable materials. They are an excellent choice for demanding applications such as CNC machines, industrial robots, and automated production lines.

2.6 Cost-effectiveness

Plastic cable carriers are more economical than their metal counterparts, both in terms of initial purchase cost and ongoing maintenance expenses. Additionally, their lightweight design reduces energy consumption in systems requiring continuous movement, contributing to overall operational efficiency.

>>See more: Comparing plastic drag chains and steel drag chains

3. Plastic drag chains from HELUKABEL

To expand our product portfolio, and to help our customers have a variety of solutions from a single source, in 2022 we, HELUKABEL, acquired EKD Systems. They are a new member of our group.

EKD Systems is one of the oldest drag chain brands established in 1970. Up to now, EKD has more than 50 years of experience in designing and manufacturing drag chains in the market.

Currently, EKD not only offers a diverse product portfolio of cable chains but can also design and manufacture according to customers' requirements. With 2D or 3D design technology, you can set criteria and consider adjusting the design accordingly until the finished product meets the requirements. This state-of-the-art technology will save you considerable time and money when looking for the right drag chain for application in the manufacturing plant.

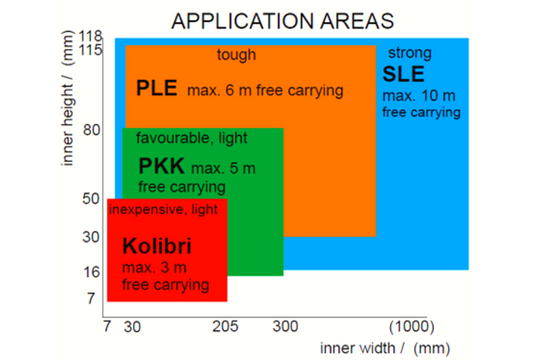

Some of this company's high-quality polyamide plastic drag chains are that you can refer to, such as Kolibri, PPK, and PLE series plastic drag chains. The difference between these product lines is the design of optimal cable and duct space for specific applications based on three factors:

- Inner height

- Width inside

- Load per meter and allowable length

In addition, the bend radius, travel speed, and travel distance of the drag chain also change when changing the above three factors.

OTHER POSTS >>> PVC CABLES VS LSZH CABLES

4. Characteristics of Kolibri plastic drag chains

4.1 Advantages of Kolibri plastic drag chains

Kolibri is a specialized range of plastic cable carrier chains designed for light-duty applications. Its innovative design features a patented opening mechanism, offering high torsional resistance and user-friendly operation. Below are some standout advantages of Kolibri cable carriers:

- Easy access with flexible opening bars

- High durability and wear resistance

- Unique divider system with clip-type separators

- Compact and space-saving design

- Integrated connectors for hassle-free installation

4.2 Technical specifications of Kolibri plastic drag chains

Kolibri plastic cable carrier chains are designed with versatile technical features to meet the needs of various light-duty applications. Below are the key technical specifications:

- Bend radius: Ranges from 15 mm to 400 mm

- Inner height: Available from 7 mm to 50 mm

- Inner width: Spans from 7 mm to 195 mm

- Weight: Varies between 0.06 kg/m and 2.7 kg/m

- Operating temperature range: From -20°C to 100°C

_any_small.png)

_any_small.png)

4.3 Sizes of Kolibri plastic drag chains

Kolibri cable carriers are available in the following versions:

- Kolibri plastic drag chain height 10

- Kolibri plastic drag chain height 13

- Kolibri plastic drag chain height 15

- Kolibri plastic drag chain height 22

- Kolibri plastic drag chain height 30

- Kolibri plastic drag chain height 40

- Kolibri plastic drag chain height 50

- Kolibri plastic drag chain height 65

5. Characteristics of PKK plastic drag chains

5.1 Advantages of PKK plastic drag chains

Developed based on years of expertise, PKK cable carriers integrate all the key benefits of plastic cable carriers into a single system:

- Flexible design with open or closed configuration

- Durable fixed bars: Secure and robust construction ensures long-lasting performance.

- Quick installation and removal: Facilitates easy maintenance and reduces downtime.

- Adjustable length

- Three-dimensional movement

5.2 Technical specifications of PKK plastic drag chains

The PKK cable carriers are designed with versatile technical specifications to meet various application demands:

- Bend radius: Ranges from 40 mm to 500 mm

- Inner height: Available from 16 mm to 80 mm

- Inner width: Spans from 30 mm to 400 mm

- Weight: Ranges from 0.6 kg/m to 3.4 kg/m

- Travel distance: Supports movement distances of up to 100 meters

- Operating temperature range: From -20°C to 100°C

_any_small.png)

_any_small.png)

5.3 Sizes of PKK plastic drag chains

The PKK plastic cable carriers are available in the following sizes:

- PKK 120

- PKK 140

- PKK 220

- PKK 240

- PKK 320

- PKK 340

- PKK 520

5.4 Types of PKK plastic drag chains

PKK plastic drag chains come in various types:

- PKK 120, 220, 320, 520

- PKK 110, 140, 210,240, 310,340, 510

- PKK 121, 221, 321, 521

- PKK 111, 141, 211, 241, 311, 341, 511

- PKK 113, 123, 143, 213, 223, 243, 313, 323, 343, 513, 523

- PKK 125, 225, 325, 525

- PKK 115, 215, 245, 315, 345, 515

6. Characteristics of PLE plastic drag chains

6.1 Advantages of PLE plastic drag chains

Some key features of PLE plastic drag chains include:

- Open or fully enclosed structure.

- Inner height up to 120 mm.

- Inner width up to 1000 mm.

- Load capacity of up to 24 kg/m, with a load-bearing length of up to 8 meters.

- Secure locking bars on both the inner and outer bend radii.

- Easy opening on both sides for convenient installation and maintenance.

- Adjustable length, allowing for shortening or extension as needed.

- Infinitely variable divider bars up to 1000 mm, offering flexibility for large-scale applications.

6.2 Versions of PLE plastic drag chains

PLE cable carriers with aluminum bars are available in the following options:

- PLE plastic drag chains: Equipped with plastic bars or slots, ensuring excellent guidance even at high speeds.

- PLS plastic drag chains: Features foam slots, ideal for applications with limited installation space.

- PLP plastic drag chains: Includes adjustable plastic dividers (PZ) for seamless customization, suitable for all requirements, including cable diameter adjustments.

_any_small.png)

_any_small.png)

7. Applications of Kolibri, PKK, PLE plastic drag chains

The 3 drag chain products with separate parameters and functions will be applied in a different part of the factory, depending on space and technical requirements.

- Kolibri plastic cable carriers are lightweight, compact, and cost-effective, making them an ideal choice for systems requiring a maximum free cable length of 3 meters. These carriers are particularly suited for small automation devices, lightweight applications such as printers, and measurement equipment.

- PKK plastic cable carriers strike a balance between flexibility and durability. They are perfect for medium-scale production lines and mechanical automation systems, offering reliable performance for free cable lengths of up to 5 meters.

- PLE plastic cable carriers are designed to endure harsh working conditions. These robust carriers are suitable for heavy industrial plants and large mechanical equipment, supporting free cable lengths of up to 6 meters.

Besides the 3 lines of plastic cable chains mentioned above, EKD Systems also offers a variety of other stainless steel cable chains.

At HELUKABEL, we offer comprehensive solutions from drag chains to electrical cable products used in drag chains and their accessories. Choosing the suitable drag chain and internal power cable will help ensure quality during operation and the life of the equipment. If your manufacturing plant needs more in-depth support to select a complete solution, please contact our engineers for more specific advice.

If you still have any concerns or questions, don't hesitate to reach out to HELUKABEL Vietnam's engineering team promptly for detailed assistance.

HELUKABEL® Vietnam

905, Nguyen Kiem Street, Ward 3, Go Vap District, Ho Chi Minh City 700000, Vietnam

Tel. +84 28 77755578 | info@helukabel.com.vn | www.helukabel.com.vn

OTHER POSTS >>> UP IN THE AIR WITH VINPEARL SKY WHEEL

>>See more: Longer service life in drag chain system