Why to choose control and signal cables from HELUKABEL?

Control cables and signal cables are used to transmit data and signals between devices that are far apart. However, with the harsh environmental and temperature conditions of the industries, specially designed control and signal cables are highly durable and able to withstand environmental impacts.

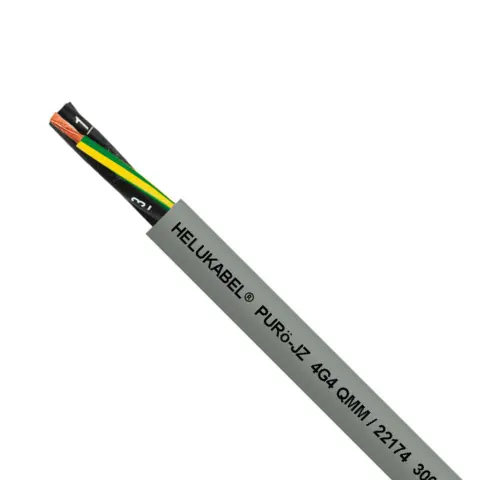

Technical structure of control cable

The technical structure of the control cable usually includes the following main components:

- Conductor core: This is the main component of the control cable, which has the function of transmitting control signals. Conductors are usually made of aluminum or aluminum and can have one or more cores depending on the usage requirements.

- Insulation: Insulators are used to provide insulation between different conductive cores and between the conductive core and other coverings. Commonly used materials are PVC (Polyvinyl chloride), PE (Polyethylene) or XLPE (Cross-linked polyethylene).

- Core grafting: Core coupling reduces intrinsic interference and provides a solid structure for the cable. Conductor cores are usually coupled in twisted pair or quad twisted structures.

- Sheath layer: Common materials used for this layer can be PVC or XLPE. This layer ensures that there is no electrical interaction between the conductive core and other encapsulation materials.

At HELUKABEL, we provide a comprehensive electrical connection solution with a series of control cables that meet technical requirements such as: anti-interference, high temperature resistance, oil resistance, chemical resistance, and microbiological resistance. object…

Furthermore, during the manufacturing process, our products are up to the standard of rigorous quality tests, conducted according to national and international standards. German national certifications (VDE) and 16 other international certifications such as (UL, SEV, SEMKO, SGS, OVE, NEMKO, CSA, IMQ, BSI, CCC, DEMKO, CE, CEB, HAR, TÜV, etc...)

Call +84 28 77755578 or email us at info@helukabel.com.vn or register for free consultation on specific control cable and signal cable types with specialized engineers by filling out the form .

Cables and wires from Germany

More than 9000+ stock items

Wide range of applications

Get a Quote & Expert Consultation

HELUKABEL's control & signal product portfolio

1. PVC control cables

Discover our products

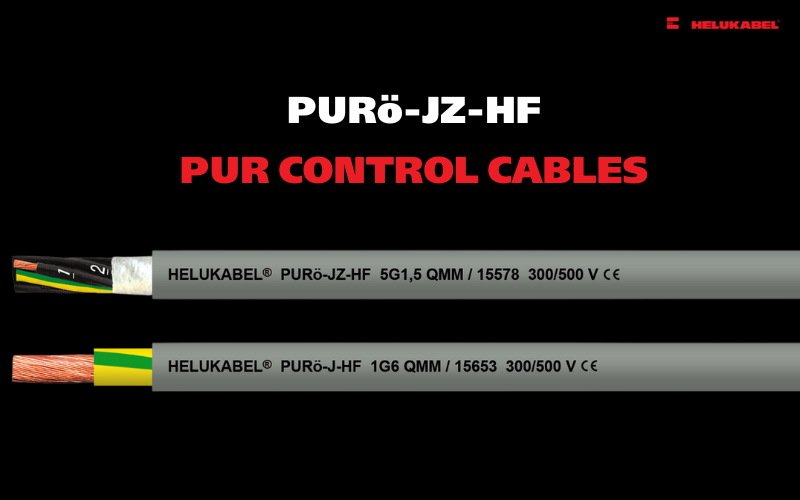

2. PUR/TPE control cables

Discover our products

3. Halogen-free control cables

Discover our products4. Silicone signal and control cables

Discover our products

5. Rubber signal and control cables

Discover our products

6. IS signal and control cables

Discover our products

7. Control and signal cables for drag chains

Discover our products

8. HAR-approved control and signal cables

Discover our products

9. UL/CSA Approved control and signal cables

Discover our productsOutstanding features of HELUKABEL's control and signal cables

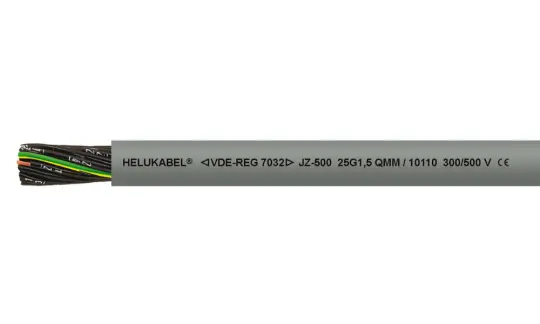

1. JZ-500 control cables

Used for flexible applications involving medium mechanical stress, allowing free movement without tensile stress and without forced motion control, in dry, damp, and wet indoor environments. However, it is not suitable for outdoor use.

Commonly used as a connection and control cable in machine tools, assembly lines, conveyor systems, production lines, plant construction, air-conditioning technology, smelters, and steel mills.

Specially selected PVC compounds ensure good flexibility, efficient handling, and quick installation.

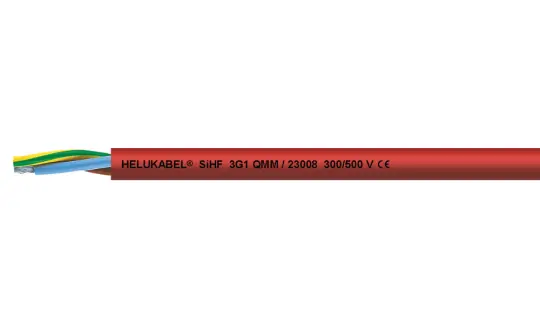

2. SiHF halogen-free, silicon cables

SiHF silicone cables were developed for use in environments where the insulation is exposed to extreme temperature variations. Thanks to their excellent resistance to environmental factors, silicone cables can operate at temperatures as low as -60°C.

These halogen-free cables are particularly well-suited for installation in power stations. They are also widely used in the steel industry, aviation, shipbuilding, and in ceramic, glass, and cement factories.

Due to the elastic properties of their core insulation, silicone cables are ideal for use as flexible connection cables.

Features of JZ-500 control cables

- Copper wire bare, extra finely stranded acc. to DIN VDE 0295 Class 5 / IEC 60228 Class 5

- PVC insulation, PVC outer sheath (compund type TM2) with grey colour

- Temperature range: -15°C to 80°C (flexing), -40°C to +80°C (fixed installation)

- Oil-resistant, flame-retardant, conditionally suitable for drag chain

- Number of cores: from 2 to 100 cores

- Minimum bending radius: 7.5x Outer-Ø (flexing), 4x Outer-Ø (fixed installation)

Features of SiHF silicone control cables

- Copper wire bare, finely stranded acc. to DIN VDE 0295 Class 5 / IEC 60228 Class 5

- Silicone insulation, silicone outer sheath with brown red colour

- Temperature range: -25°C to 180°C (flexing), -60°C to +80°C (fixed installation)

- Halogen-free, high flashpoint

- Resistant to: ozone, oxygen, weathering effects, alcohols, dilute acids, alkalis, saline solutions, oxidising agents...

- Minimum bending radius: 7.5x Outer-Ø (flexing), 4x Outer-Ø (fixed installation)

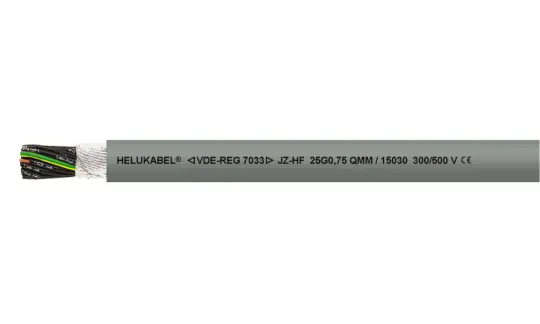

3. JZ-HF control cables

Used for frequent lifting and bending stress in machine and tool construction, robotics, and on permanently moving machine parts. These cables allow free movement without tensile stress or forced motion control, and have proven their reliable performance in drag chain applications.

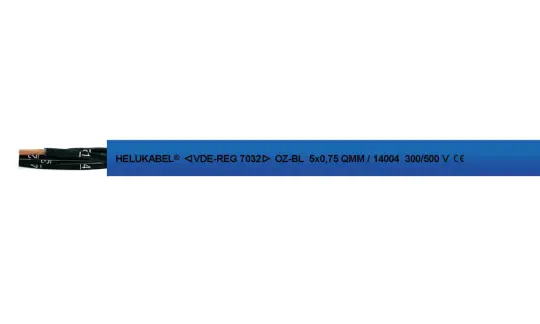

4. OZ-BL control cables

Used for flexible applications involving medium mechanical stress, with free movement, without tensile stress, and without forced motion control.

Designed for explosion-endangered areas marked as intrinsically safe (blue) (ignition protection type -i-), this flexible control or measurement cable is intended for intrinsically safe systems in measurement and control technology. These systems are not earthed and have a separate power circuit.

Features of JZ-HF control cables

- Copper wire bare, extra finely stranded acc. to DIN VDE 0295 Class 6 / IEC 60228 Class 6

- PVC insulation (compund type Z 7275), oil-resistant PVC outer sheath

- Temperature range: -10°C to +80°C (flexing), -40°C to +80°C (fixed installation)

- Number of cores: from 2 to 65 cores

- Oil-resistant, flame-retardant, suitable for drag chains

- Minimum bending radius: 7.5x Outer-Ø (flexing), 4x Outer-Ø (fixed installation)

Features of OZ-BL control cables

- Copper wire bare, finely stranded acc. to DIN VDE 0295 Class 5 / IEC 60228 Class 65

- PVC insulation (compound type Z 7275), PVC outer sheath, blue colour

- Temperature range: -15°C to +80°C (flexing), -40°C to +80°C (fixed installation)

- Resistant to oil, UV, weathering effects

- Suitable for outdoor use

- Minimum bending radius: 7.5x Outer-Ø (flexing), 4x Outer-Ø (fixed installation)

Order Now on HELUKABEL E-Store – Fast & Easy!

If you still have any concerns or questions, don't hesitate to reach out to HELUKABEL Vietnam's engineering team promptly for detailed assistance.

HELUKABEL® Vietnam

| Address | 905, Nguyen Kiem Street, Ward 3, Go Vap District, Ho Chi Minh City 700000, Vietnam |

| info@helukabel.com.vn | |

| Hotline | +84 28 77755578 |

| Website | www.helukabel.com.vn |

| Discover our products and place orders | Tiki | Shopee | Lazada | Product finder |

| Follow us on | Facebook | LinkedIn | Instagram | Youtube | Zalo | WhatsApp | Tiktok | Spotify |

FAQs about control and signal cables

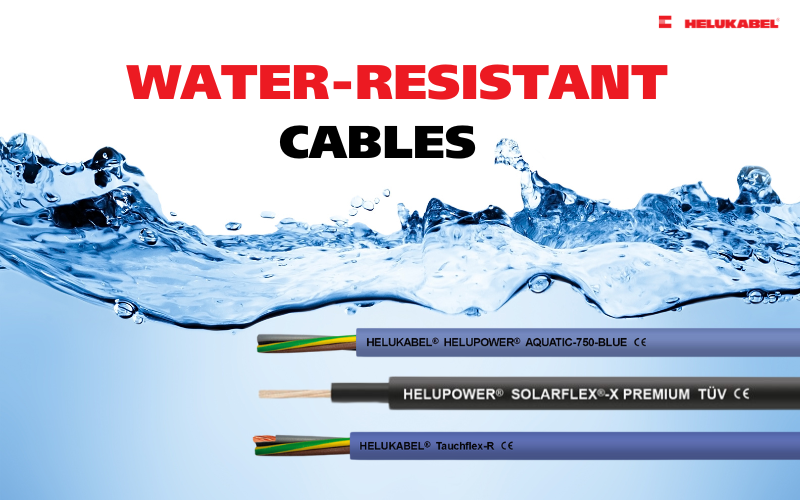

This is a very popular cable in many industries thanks to its stable insulation, water resistance, flexibility, and durability. PVC material of this cable line is popular and popular in the market.

PUR power cables are increasingly important in the cable industry because they do not contain halogens when a fire occurs, helping to ensure the safety of human life. Besides, this cable line has strong durability, less abrasion and ensures flexibility.

TPE power cables are mainly used in harsh conditions such as chemical environments or high temperatures.

Besides the requirements for excellent electrical and thermal insulation ability, the plus point of this product line is that it does not contain halogens, which reduces the risk of loss of life and property in fires. (Halogen is a substance that, when burned, produces a toxic gas.)

Silicone cable has the characteristics of heat-resistance, chemical-resistance, water-resistance and flexibility. HELUKABEL silicone power cables are widely applied in many industries, especially those requiring high temperatures such as steel manufacturing industry.

Rubber power cable (rubber) is safe with good insulation, so it is often used in households, factories, factories, offices, companies... This cable line can withstand the impact of the environment.

IS (IS: Intrinsically Safe) signal and control cable is a connection and control cable for safe rooms. This line of cables is used in hazardous areas to help eliminate fire hazards and protect cables from UV rays as well as weather.

This type of cable is suitable for application in machine parts that are constantly in motion, such as industrial robots, packaging machines, machine tools, drag chains and automation systems. The products have a special structure with the ability to withstand high mechanical stress, limit damage and ensure stable power transmission.