Torsion-resistant cables for robotics applications

The torsion-resistant cables address the challenges faced in robotics applications. Explore our latest catalog to discover our torsion-resistant cables!

1. Challenges for cables used in robotics applications

The robotics industry is advancing rapidly, leading to a growing demand for specialized cables. As robots become increasingly complex, the electrical cables that power and control them must withstand constant movement and harsh conditions without compromising performance. Manufacturers today are developing electrical cables capable of enduring the challenges presented by advanced robotics, frequently employing innovative materials and new design techniques to meet these technological demands. This progress is crucial in ensuring that electrical cables are as advanced as the robots they support.

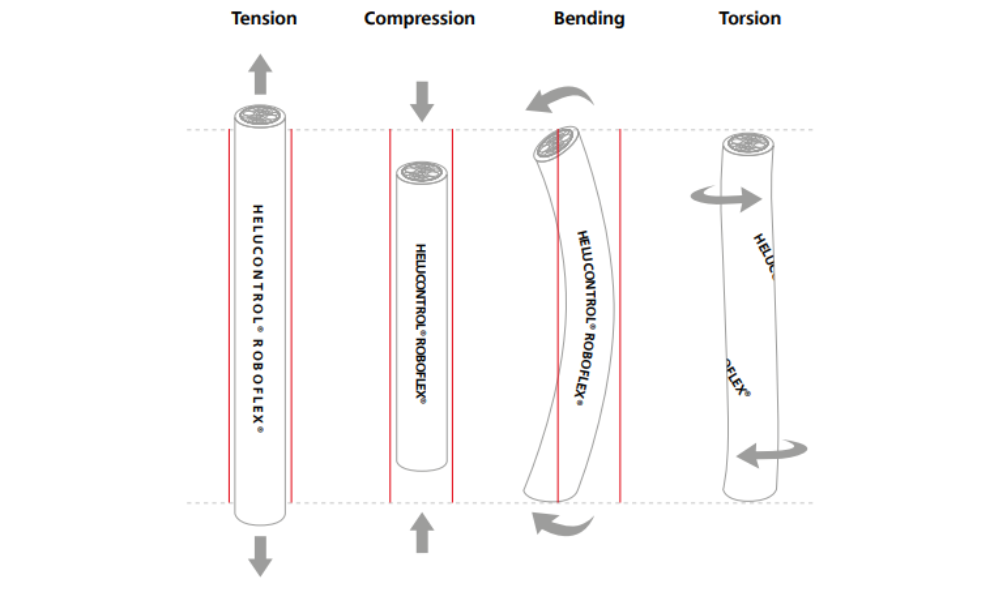

Cables used in robotics face various stresses: millions of continuous bends and twists create significant compression and tensile forces, putting considerable strain on the cable. Cable design must also account for rapid acceleration and deceleration, making abrasion resistance, cut resistance, and tear resistance essential. Additionally, high temperatures commonly encountered in robotic applications add another layer of stress to the cables.

2. Torsion-resistant cables for robotics applications

Torsion and tensile forces are factors that standard cables cannot withstand as effectively as cables specifically designed for robotics. Robotic arms and components bend millions of times, and standard cables are unable to endure such demands in these applications.

2.1 Specialized design of torsion-resistant cables

To withstand millions of bends in industrial applications, robotic cables require a specialized design. Advanced torsion-resistant cables for robots are optimized for flexibility. Every component - from materials and shielding structure to the outer sheath - is designed to adapt to changing angles and diameters. This type of cable can handle the complex movements of robots. Within its operating range, torsion-resistant cables ensure efficient data transmission.

2.2 Torsion-resistant cables are essential solutions for 6-axis robots

In modern industrial applications, 6-axis robots are increasingly used to optimize production efficiency and automation. With the ability to move flexibly in six different directions, these robots must perform millions of complex movement cycles, including bending and twisting. As a result, torsion-resistant cables are essential components, ensuring stable and durable operation in demanding environments.

Torsion-resistant cables are specially designed to withstand the intense impact of continuous motion, featuring a durable material structure and protective sheath that minimizes damage risks. This design allows the cable system to adapt and respond flexibly to both horizontal and vertical torsional movements, reducing the likelihood of breaks or wear over time.

3. HELUKABEL’s torsion-resistant cables

HELUKABEL's product portfolio includes a wide range of cables, wires, and connection technology specially designed for high-demand robotic applications. In our new Robotics Catalog, we have compiled these products in a concise, easy-to-navigate format. Discover innovative industry solutions like the Roboflex torsion-resistant cables, along with control cables, motor cables, sensor cables, hybrid cables, and data, network, and bus cables. We’re also ready to develop customized cables and complete system solutions to ensure smooth operation for your robotic applications.

3.1 Data cables

HELUKABEL's product catalog of torsion-resistant data cables for the robotics industry includes a variety of products such as:

These data cables are specifically designed to transmit data and monitoring signals, tailored for torsional and bending movements. These torsion-resistant cables are ideal for use in assembly and welding robots, in material handling and automation centers, in transport and conveyor systems, and on rotary and swivel tables. The ROBOFLEX cable series is engineered to withstand 3D movements and torsional loads, meeting the highest demands for mechanical, chemical, and thermal resilience in advanced applications.

3.2 Control cables

Some control cables for robotics applications include:

HELUCONTROL® ROBOFLEX® PUR UL/CSA

HELUCONTROL® ROBOFLEX®-D PUR UL/CSA

HELUCONTROL® ROBOFLEX® 2001

HELUCONTROL® ROBOFLEX® 2001-D

3.3 Motor cables

The HELUPOWER® ROBOFLEX® PUR UL/CSA and HELUPOWER® ROBOFLEX®-D PUR UL/CSA motor cables offer the following features:

- High load capacity: These cables are designed to withstand 3D movements and torsional loads, meeting the highest demands for mechanical, chemical, and thermal resilience in challenging applications.

- Flexible structure: The HELUPOWER® ROBOFLEX® series features smooth, high-quality insulation that enables easy sliding, with optimized core stranding to ensure long service life in applications requiring combined bending and torsion movements.

- High durability: With a robust protective outer sheath, these two motor cables offer long-lasting and reliable performance, even under harsh operating conditions.

3.4 Hybrid cables

HELUKABEL's torsion-resistant cables also include hybrid cables:

HELUPOWER® ROBOFLEX® HYBRID PUR UL/CSA

HELUPOWER® ROBOFLEX® HYBRID-D PUR UL/CSA

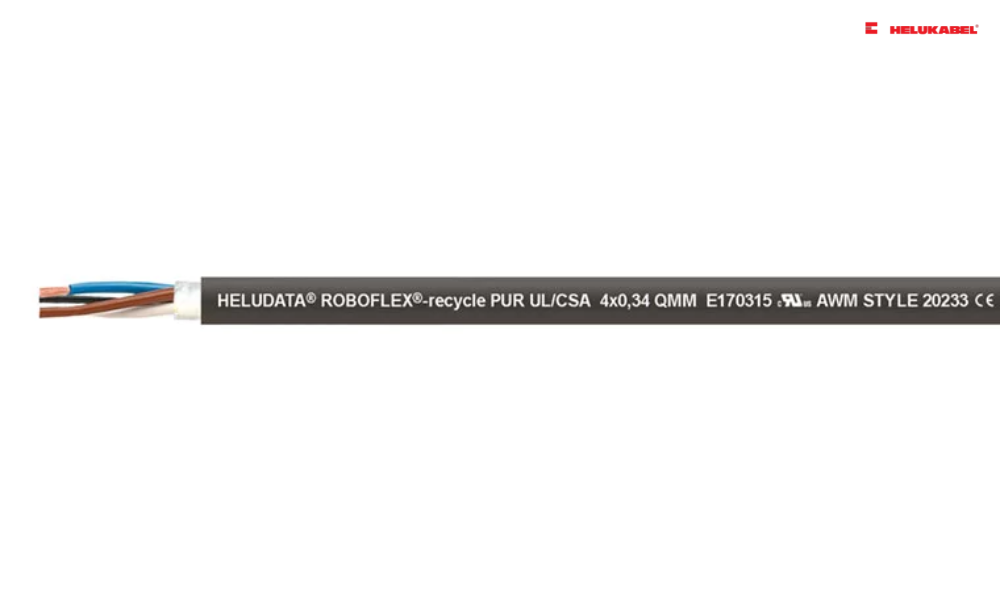

3.5 Welding spark resistant sensor cable

The HELUDATA® ROBOFLEX®-recycle PUR UL/CSA is a sensor cable designed to resist welding sparks and oil, suitable for use in robots (torsional load) as well as in drag chains (dynamic load). This cable series is ideal for applications in automation technology, machine and plant engineering, assembly and welding robots, machine tools, foundries, and rolling mills. With a temperature resistance of up to 105°C, it can be used in environments near engines and areas with increased heat radiation. The highly abrasion and notch-resistant outer sheath ensures long service life and cost efficiency. Additionally, the recyclable cable material contributes to environmental protection efforts.

Benefits of using HELUDATA® ROBOFLEX®-recycle cables

- Saving money over cross-linked cables

- Halogen-free

- Heat-resistant from -40°C bis 105°C

- Good resistance to oil, chemicals and welding sparks

- UL and CSA approval

- Suitable for drag chains and robots, tested with 10 million changing bending and torsion cycles

3.6 PROFInet and BUS cables

Some notable torsion-resistant cables include:

- HELUKAT® PROFInet R+ CAT.5e SF/UTP PUR ROBOTIC: This cable offers excellent transmission characteristics with double shielding and is designed for applications with torsional loads, such as in robots.

- HELUKAT® 100T CAT.5 SF/UTP PUR TORSION: Characterized by high reserve capacity and outstanding performance, even after exposure to extreme conditions. Thanks to its clever structure, this electric cable can also achieve a long mechanical service life.

- HELUKABEL® BUS Cables Profibus L2 Torsion: This cable features a special torsion construction that allows it to be twisted and is completely halogen-free due to the use of a PUR sheath. The Festoon version is used for hanging or moving loads in chain applications.

Additionally, users may also refer to products such as HELUKAT® 600T CAT.7 SF/FTP PUR TORSION, HELUCOM® I-V4Y(ZN)Y (B), I-V4Y(ZN)11Y (C), and A-V(ZN)11Y

If you still have any concerns or questions about torsion-resistant cables, don't hesitate to reach out to HELUKABEL Vietnam's engineering team promptly for detailed assistance.

HELUKABEL® Vietnam

| Address | 905, Nguyen Kiem Street, Ward 3, Go Vap District, Ho Chi Minh City 700000, Vietnam |

| info@helukabel.com.vn | |

| Hotline | +84 28 77755578 |

| Website | www.helukabel.com.vn |

| Discover our products and place orders | Tiki | Product finder |

| Follow us on | Facebook | LinkedIn | Instagram | Youtube | Zalo | WhatsApp | Tiktok | Spotify |