What are electric cables? Common types of electrical cables

Industries require different types of cables, while meeting strict requirements. Learn about common types of cables through the following article!

1. What are electric cables?

Electric cable is a type of conductor made up of two or more metal wires twisted or braided together, forming a homogeneous structure. The outside of the electric cable is an insulating and protective sheath. These covers are responsible for protecting the cables from physical factors such as impact and stretching, as well as pressure from natural environmental factors such as water, UV rays and sunlight...

Each line of electric cables will have its own technical characteristics, depending on the specific application as well as the intended use, users can choose the appropriate type of electric cable.

>>Find out more: How to differentiate between electric cables and control cables?

2. The role of electric cables

Electrical cables transmit electrical power from the power supply to various equipment, machines, and electrical systems in the manufacturing environment. Electrical cables play an important role in industrial sectors for the following reasons:

- Reliability and stability: In industrial environments, power outages or signal fluctuations can disrupt production, affect performance, and cause damage to the business, even damaging important equipment. Therefore, quality electric cables help the production process run stably and continuously, ensuring effective operation of the electrical system.

- Withstand harsh environments: In industrial environments, operating and being exposed to diverse, yet extreme environments such as high temperature, chemicals, dust, humidity... is unavoidable. Therefore, choosing and using electric cables equipped with appropriate resistant materials (PVC, XLPE, PUR...) is an important factor to minimize the risk of incidents and risks, and increase longevity of electrical equipment and systems.

- Improve performance and save energy: Using high-quality electric cables minimizes energy loss during transmission, thereby increasing the performance of electrical equipment and reducing electricity costs.

- Labor safety: Electrical cables used in industry are designed and guaranteed to comply with strict safety standards, minimizing the risk of labor accidents and explosions due to short circuits. With a sturdy structure and high load-bearing capacity, industrial electrical cables help avoid unwanted incidents, protecting employees and business assets.

3. Structure of electric cables

The structure of an electric cable is a complex system including the following components:

3.1 Conductor

The conductor is usually made of copper or aluminum, has good electrical conductivity, and plays the role of transmitting electricity from the power supply to electrical consuming devices and systems. The size of the electric core is usually determined by one of two indices: AWG index - American Wire Gauge (according to American standards) or mm2 (standards of European countries).

3.2 Insulation sheath

The insulation sheath surrounds the conductive core, preventing electricity from flowing to the outside, avoiding electric leakage or causing risks to users. Some common insulating materials include:

- PVC (Polyvinyl chloride) is a type of insulating sheath with relatively low cost and high durability. Besides, with the water-resistant and fire-retardant properties to a certain extent, in addition to being a popular insulating material, PVC is also used to make electrical cable sheaths.

- XLPE (Cross-Linked Polyethylene) has higher heat resistance than PVC, and also has better mechanical strength. Therefore, XLPE is often used in applications that need to withstand high temperatures and in chemical environments.

- Rubber: extremely heat resistant, resistant to ozone, UV and chemicals. Rubber is often used in special applications requiring high heat resistance and durability such as in the electronics industry and the automotive industry.

3.3 Shield and armor

Electric cables can be equipped with an additional anti-interference layer to avoid flickering and instability during signal transmission. Protective armor is an outer or inner jacket with properties that resist harmful external influences.

3.4 Outer sheath

This is the component that plays the role of protecting electric cables from external physical factors such as impact, cutting and abrasion...

>>Find out more: The important role of shield and armour in cables

_any_large-2.png)

4. Classification of electric cables

There are many ways to classify electric cables. The following are some typical ways to classify electric cables:

4.1 According to power grids

There are three types of power cables designed to meet the power transmission needs corresponding to 3 types of power grids:

- Low voltage cables: This type of wire is often applied in civil and industrial projects. Low voltage cables are capable of operating at pressures not exceeding 0.6/1kV. These wires are often installed in elevator systems.

- Medium voltage cables: Used to transmit electricity at a higher voltage than low voltage. Normally, medium voltage cables have voltages from 3kV to 36kV, with 24kV being the most popular in Vietnam. These types of cables ensure the stable and safe transmission of power from the supply source to the points of use.

- High voltage cables: This type of cable is often hung on high poles and is insulated to ensure safety. High voltage cables are used at the highest voltage of the three types, usually 35kV. Hanging high voltage cables in the air not only helps save space but also ensures safety during the transmission of electricity.

4.2 Classification by the number of conductors

Based on the number of conductors, electric cables can be classified into 2 main types:

- Single core cables : single core cables are made up of a single conductive core. Single core cables are commonly used in residential electrical systems, supermarkets, shopping centers...

- Multicore cables: consists of many conductive cores braided together. Easy splicing, malleability, effective electrical and thermal conductivity are outstanding features of multi-core cables.

4.3 Classification according to conductor material

Copper cables

Copper cables are electrical cables made of copper - a metal that conducts electricity and heat well. Electrical applications of copper cables vary, including generators, power distribution, telecommunications, electronic circuits, and construction wiring.

Aluminum cable

Aluminum cables are electrical cables made from aluminum instead of copper. This type of cable is used to transmit and distribute electricity in homes, aircraft, and power grids. Aluminum cables are lighter, stronger, and cheaper than copper cables. Besides, aluminum cable is also known for its good electrical conductivity, light weight, and corrosion resistance.

4.4 Classification by outer sheath materials

Based on the outer sheath material, cables can be classified into the following types:

- PVC sheathed cables: control cable JZ-500, F-CY-JZ; data cable PAAR-TRONIC-CY, PAAR-TRONIC-Li-2YCYv; TOPFLEX-EMV-2YSLCY-J.

- PUR sheathed cables: PURo-JZ-HF, JZ-500 PUR control cables; SUPER-PAAR-TRONIC-C-PUR data cable; TOPSERV 121 PUR cable.

- Cables with TPE sheath: HELUCHAIN MULTISPEED 522-TPE UL/CSA, TOPSERV 600 VFD

- Rubber cables: cable series H05RN-F/ 05RN-F, H07RN-F/ 07RN-F.

- Halogen-free cables: JZ-500 HMH/ OZ-500 HMH control cable; SiHF heat-resistant cable, THERMFLEX 180 EWKF; MULTIFLEX 512 PUR.

4.5 Classification by area of usage

Classifying electric cables according to area of usage is the most popular method, helping users easily choose the right type of cable for their intended use.

| Cables | Characteristics | Examples |

| Control cables | The function of control cables is to transmit control signals and electricity to control devices in automation systems, machinery, and equipment in manufacturing plants... |

|

| Data cables | Data cables transmit data from one device to another. This type of cable is often used in computer networks, communication systems, and various electronic devices to transmit digital information. |

|

| Motor cables | For a device or machine that requires a lot of power, such as a motor, motor cables come into great use. Motor cables usually have a voltage class of 600V/1000V, while control cables usually have a voltage class of 300V/500V. |

|

| Servo cables | Servo cables are used to connect frequency converters to motors in electrical engineering. This cable series is designed for quick connection of computer numerical control (CNC) machines, intelligent servo drives and temperature controllers. |

|

| Feedback cables | Feedback cables are integrated into factories and industrial machinery to transmit signals between servo motor position sensors and control systems. These signals often include information about the machine's speed and position. |

|

| Ethernet cables | Ethernet cables are an important part of industrial automation. This type of cable is used to transmit data between sensors, actuators, and other electronic components in machines and systems. The performance of ethernet cables enables better and faster data transmission to meet the growing needs of industries. |

|

| Anti-inteferences cables | A type of cable specifically designed to prevent and minimize the effects of electromagnetic interference (EMI) on electrical current transmitted through electrical conductors. There are 3 basic types of anti-interference coating: aluminum foil wrap (Al foil), tinned copper braid, many small fibers wrapped around in a spiral form. |

|

| Fire-resistant cables | Fire-resistant cables can withstand high temperatures. The characteristic of fire-resistant cables is that they still operate normally for a certain period. Therefore, these cables are often used to prevent fire spread, while minimizing the possibility of fire and explosion. |

|

| Flame-retardant cables | Flame-retardant cables can prevent fire from spreading when an incident occurs. The characteristic of this cable line is that the fire only burns at a certain distance, without spreading to others. |

|

| Power cables | Power cables and medium voltage cables are used to transmit energy and ensure reliable power supply in many different sectors. These infrastructure cables are typically installed underground, in pipes, or outdoors. |

|

| Custom cables | Custom cables are specifically designed according to the user's needs and specifications. This is a good choice when existing products cannot meet the needs of the application or when a modified product can meet the requirements better. Custom cables are tuned to the voltage, current, and other operating parameters tied to the specific application, so they can deliver reliable performance over longer periods of time than standard cables. |

>>Find out more: Cables and wires from HELUKABEL

>>Find out more: What makes standard cables distinct from custom cables

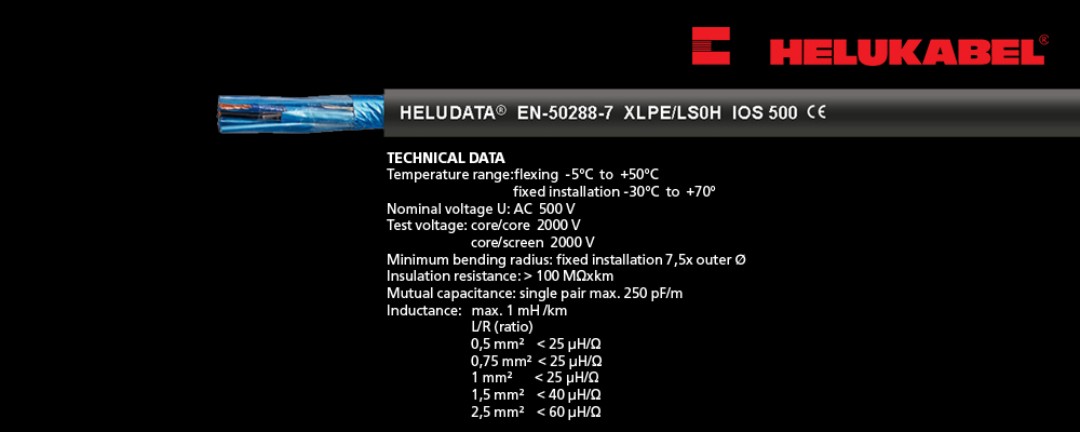

5. Some basic specifications of cables

The technical specifications of cables not only help users meet the technical standards of the application but are also an important factor for the safety and performance of industrial electrical systems. A few basic specifications:

- Voltage range: This is the maximum voltage level that the cable can withstand without causing problems or losses. Typically, common voltage ranges for industrial cables are from 600V to 35kV, depending on the specific application.

- Temperature range: This is the temperature range in which the cable can operate without causing problems. This specification usually includes the maximum and minimum temperatures the cable can withstand, for example -40°C to 90°C.

- Conductive core size: The size of the conductive core directly affects the cable's ability to conduct electricity. This parameter is usually measured by the diameter or cross-sectional area of the conductor core, expressed in mm2 or AWG (American Wire Gauge) units.

- Type of sheath: Sheath provides insulation and protection for electric cables from external factors. There are different types of covers such as PVC, XLPE, rubber, and each type is suitable for some specific applications.

- Standards: Recommended and followed standards are important to ensure the quality and safety of industrial electrical cables. Popular standards include VDE, HAR, UL, CSA…

6. How much do electric cables cost? Latest electric cable price list (Update)

When choosing and using electrical cables, the price of electrical cables is one of the most important factors that consumers consider. This price can vary based on several factors, including:

- Type of cables: Prices differ between household electrical cables, industrial electrical cables, or specialized cables such as fire-resistant cables and anti-interference cables. Specialized cables like fire-resistant or anti-interference types are usually more expensive because they are designed to withstand harsh environments, ensure safety during fires or signal interference, and enhance the stability and durability of the system.

- Material and construction: Cables made from pure copper are typically more expensive than aluminum cables due to copper's superior electrical conductivity and efficiency.

- Brand: Well-known brands with a reputation for quality often come with higher prices compared to lesser-known or uncertified brands.

- Standards and certifications: Electrical cables that meet international standards or have technical certifications tend to be priced higher due to their guaranteed performance and safety.

- Market conditions: The price of cables can fluctuate depending on supply and demand and the cost of raw materials. For instance, when raw materials such as copper, aluminum, or insulation materials are scarce or transportation costs increase, the product price will also rise.

The price list for electrical cables from HELUKABEL can serve as a reference for users:

| Types of cables | Unit | Price (VNĐ/ Meter) |

| HELUKABEL JZ-500 control cables | Meter | 26.100 - 79.000 |

| HELUKABEL JZ-600 control cables | Meter | 37.800 - 58.000 |

| HELUKABEL F-CY-JZ control cables | Meter | 43.200 - 141.000 |

| HELUTHERM temperature-resistant cables | Meter | 2.970 - 4.680 |

| H05V-K single core cables | Meter | 450 - 810 |

| H07V-K single core cables | Meter | 1.080 - 1.800 |

| HELUKAT 450 F/FTP FRNC Ethernet cables | Meter | 39.600 - 44.000 |

| HELUKAT PROFInet type A PVC Ethernet cables | Meter | 78.300 - 87.000 |

| HELUKAT IND 100S ECO SF/UTP PUR Ethernet cables | Meter | 81.900 - 91.000 |

| PAAR-TRONIC-CY data cables | Meter | 36.000 - 53.000 |

| TRONIC (LiYY) data cables | Meter | 19.800 - 41.000 |

| HELUKABEL PAAR-TRONIC-Li-2YCYv data cables | Meter | 93.600 - 104.000 |

| HELUDATA UL 20276 | 2 X 2 X 22 AWG data cables | Meter | Khoảng 35.100 |

| HELUDATA UL 2464 | 1 X 2 X 16 AWG data cables | Meter | Khoảng 53.100 |

| HELUDATA UL 2919 | 1 x 2 x 24 AWG data cables | Meter | Khoảng 37.800 |

| HELUKABEL EN-50288-7 XLPE/PVC OS 500 instrumentation cables | Meter | 108.000 |

| HELUKABEL EN-50288-7 XLPE/PVC OSA 500 instrumentation cables | Meter | 76.000 - 129.000 |

| HELUKABEL HELUSOUND Mikrofonkabel audio cables | Meter | 63.900 - 71.000 |

| HELUKABEL HELUSOUND 400 Lautsprecherkabel audio cables | Meter | 88.200 - 98.000 |

| HELUKABEL SOLARFLEX-X H1Z2Z2-K DC cables | Meter | 42.300 - 110.000 |

Note: The electrical cable prices provided above are for reference only and may vary depending on the specific time. For the most accurate and up-to-date pricing information, please contact HELUKABEL Vietnam’s sales team.

If you still have any concerns or questions, don't hesitate to reach out to HELUKABEL Vietnam's engineering team promptly for detailed assistance.

HELUKABEL® Vietnam

| Address | 905, Nguyen Kiem Street, Ward 3, Go Vap District, Ho Chi Minh City 700000, Vietnam |

| info@helukabel.com.vn | |

| Hotline | +84 28 77755578 |

| Website | www.helukabel.com.vn |

| Discover our products and place orders | Tiki | Product finder |

| Follow us on | Facebook | LinkedIn | Instagram | Youtube | Zalo | WhatsApp | Tiktok | Spotify |