A thorough look into anti-interference cables and technical requirements

Signal cables that are equipped with anti-interference layers shall meet certain standards. Let’s delve into this topic through the following article.

1. Overview of anti-interference signal cables?

1.1 What are anti-interference signal cables?

An anti-interference signal cable is a type of electrical cable designed to transmit signals, sounds, and images between various points and mechanical devices within an electrical system. The primary purpose of these cables is to ensure continuous and accurate data transmission, maintaining the quality of information without interference.

Structurally, anti-interference signal cables bear a strong resemblance to standard electrical cables, comprising key components such as a conducting core, an insulating sheath, and an outer sheath. However, to meet the demands of high-accuracy signal transmission, these cables are equipped with an additional anti-interference layer. This layer protects against environmental interference, ensuring the integrity and performance of the entire system.

Discover HELUKABEL's portfolio for shielded control and signal cables

1.2 Characteristics of anti-interference signal cables

Anti-interference signal cables exhibit several notable features, including:

- Shielding: is applied to the outer sheath of the cable to minimize the impact of signal interference during data transmission.

- Insulating sheath: The insulating sheath of the anti-interference cables are made from high-quality insulating materials such as rubber and PVC, offering high elasticity and the ability to withstand harsh environmental conditions. Additionally, depending on specific application requirements, signal cables can be equipped with features such as oil resistance, fire resistance, and high-pressure resistance.

- Temperature resistance: The cables can withstand temperatures up to 70°C.

2. A thorough look into interference and sources of interference

2.1 The role of shielding in signal cables

A cable is composed of many independent, yet crucial components. The insulation sheath alone is insufficient to protect the cable from interference during signal transmission. Therefore, the anti-interference layer plays an increasingly essential role, especially in industrial environments. As control and signal transmission systems become more complex and transmission distances increase, the risk of damage due to electromagnetic interference (EMI) rises exponentially. Depending on the specific application, electrical cables can be affected by various types of interference, including EMI (Electromagnetic Interference), RFI (Radio Frequency Interference), and ESI (Electrostatic Interference).

2.2 Sources of interference

Basically, there are four types of signal interference:

- Static noise: This occurs when electric fields distort the signal, but it can be minimized by using continuous foil shields that provide 100% shielding efficiency and by employing proper grounding techniques.

- Magnetic noise: originates from large AC motors, transformers, and knife switches, and can induce currents in nearby devices. The simplest and most effective way to eliminate this interference is to use twisted pair signal wires.

- Common mode noise: This issue results from current flowing between points with different potentials within the system. Addressing this problem requires a carefully designed and properly installed electrical and grounding system.

- Crosstalk: This refers to the excessive occurrence of pulsed DC signals or standard AC signals between two or more nearby wires or cables. The most effective mitigation method is the use of individually shielded twisted pairs.

After identifying the source of interference, users can select the appropriate types of shields. Basic types of shields include:

- Al foil

- Tinned copper braid

- Multiple filaments wrapped around spirals

3. Technical requirements for anti-interference signal cables

3.1 Shielding in signal cables

Shield is an effective method for preventing interference in signal cables. This shielding surrounds the conductive or signal cores inside the cable and mitigates EMI in two ways:

- It can reflect interference signals.

- It can absorb noise and conduct it to the ground.

In both cases, some energy may still pass through the shielding, but it is attenuated to a level that does not cause interference. Signal cables offer varying levels of interference protection, providing different degrees of anti-interference effectiveness. The required level of interference protection depends on several factors, including the environment in which the cable is used and considerations such as the cable's diameter, weight, and flexibility.

In reality, the purpose of the shielding layer is to ground any noise it picks up. The importance of this cannot be overstated, as failure to understand this can render anti-interference measures ineffective. The signal cable jacket and its termination must provide a low-impedance path to ground. Shielded cables that are not properly grounded will not function effectively. Any interruption in the transmission line can increase impedance and reduce the effectiveness of anti-interference measures.

| Aluminum foil | Tinned copper braid | Multiple filaments wrapped around spirals | |

| Description | Use aluminum foil to prevent high frequency interference | Use small diameter tinned copper braid | Use copper or tinner copper braid |

| Flexibility | Poor | Good | Excellent |

| Coverage | 100% | 90% | 90-95% |

| Regular frequency range | High frequency (over 100MHz) | Low to mid frequency (up to 100MHz) | Low frequency (up to about 1MHz) |

3.2 Practical considerations for choosing anti-interference signal cables

When selecting anti-interference signal cables, consider the following factors:

- Matching shielding to application needs: Ensure the anti-interference shielding suits the application's requirements. In moderately disturbed environments, a single layer of aluminum foil may provide adequate protection. In areas with higher interference, use more robust anti-interference covers.

- Cable suitability: Choose a cable appropriate for the application. Signal cables subjected to repeated bending often use spirally wound shields instead of braided ones. Avoid aluminum foil shielding for flexible cables, as continuous bending can cause it to tear.

- Proper grounding: Ensure equipment connected by cables is properly grounded. Use grounding whenever possible and check the connection between the ground point and the device. Effective elimination of interference depends on a low-resistance path to ground.

- Single-end grounding: Ground the cable at one end to eliminate the possibility of ground loops.

- Cable connectors: Tinned copper braid shielding can provide 70-95% protection from EMI. While aluminum foil wraps offer 100% protection, they can be more challenging to use, especially with cable connectors. Ensure that the connector design maintains consistent interference protection with the cable.

4. HELUKABEL’s anti-interference signal cables

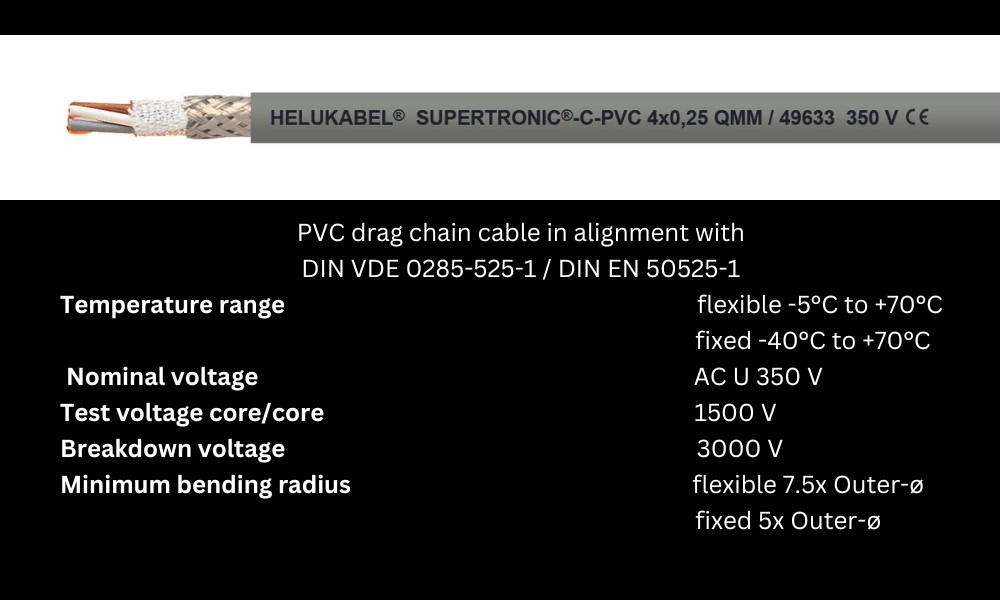

4.1 SUPERTRONIC®-C-PVC signal cable

Outstanding features of SUPERTRONIC®-C-PVC cable include:

- Copper wire bare, extra finely stranded

- Screen: braided screen of tinned copper, approx. coverage 85%

- The outer sheath is made from special PVC

- Oil-resistant

- Low adhesion

These cables are ideal for the use in drag chain applications; for frequent lifting and bending stress in machine and tool construction, in robotics and on permanently moving machine parts. A long service life also guarantees reliable function and high efficiency.

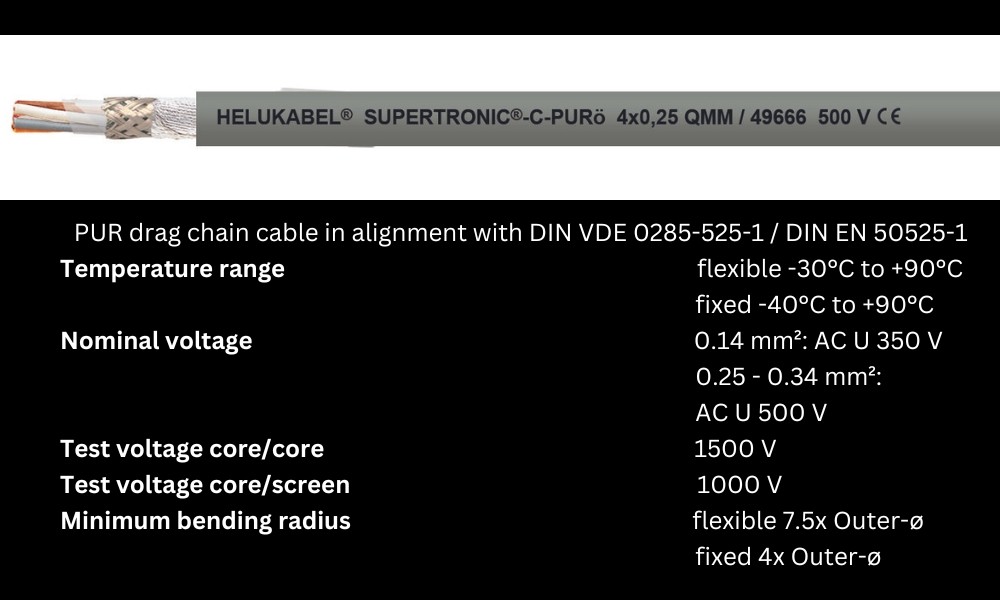

4.2 SUPERTRONIC®-C-PURö cable

The SUPERTRONIC®-C-PURö cable is characterized by the following features:

- Highly abrasion-resistant, notch-resistant, tear-resistant, cut-resistant, wear-resistant, low adhesion

- For outdoor use

- Halogen free

This cable is suitable for installation in dry, damp and wet rooms, as well as outdoors. With free movement, without tensile stress and without forced motion control capabilities, these cables have proven their reliable performance in drag chain applications, for frequent lifting and bending stress in machine and tool construction, in robotics and on permanently moving machine parts.

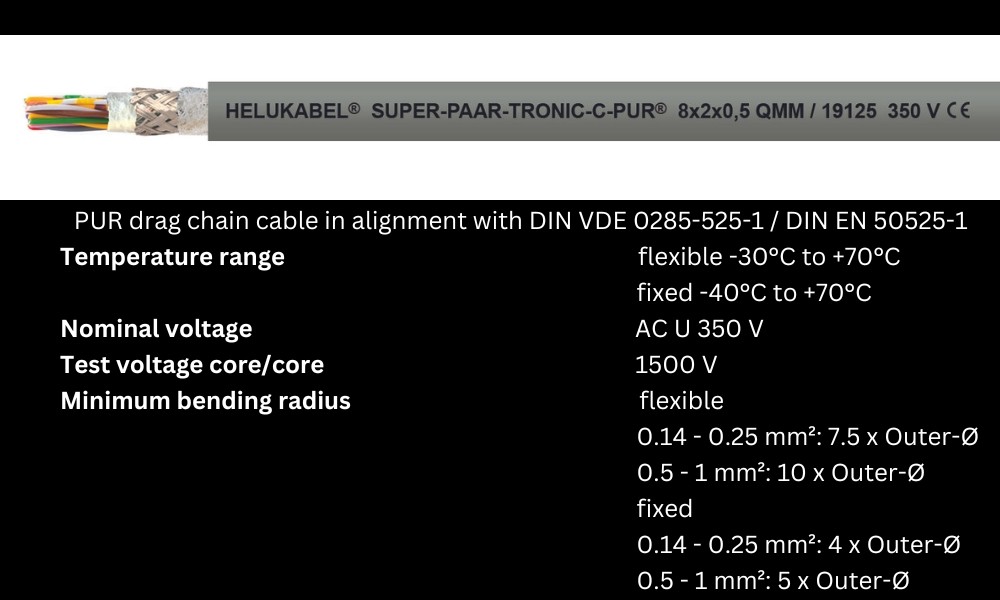

4.3 SUPER-PAAR-TRONIC-C-PUR® cable

SUPER-PAAR-TRONIC-C-PUR® cable exhibits the following characteristics:

- Resistant to oil, UV radiation, ozone, oxygen, weathering effects, hydrolysis, microbes, coolants, hydraulic fluids, acids, alkalis, greases, seawater, and wastewater

- For outdoor use

- Highly resistant to alternate bending strength

- Halogen free

Drag chain compatible cable SUPER-PAAR-TRONIC-C-PUR® is suitable for permanent flexible operations in machinery, machine tools, robot technics, for movable automated machinery parts and multi-shift-operation as a transmission-cable. This highly flexible cable with enhanced sliding capabilities by using PP-core insulation and an adhesion-low and cut-resistant PUR-outer sheath, guarantees optimum durability and is highly economic.

If you still have any concerns or questions, don't hesitate to reach out to HELUKABEL Vietnam's engineering team promptly for detailed assistance.

HELUKABEL® Vietnam

905, Nguyen Kiem Street, Ward 3, Go Vap District, Ho Chi Minh City 700000, Vietnam

Tel. +84 28 77755578 | info@helukabel.com.vn | www.helukabel.com.vn