Halogen-free control cables: essential for outdoor use

What are the benefits of using halogen-free control cables! Let’s find out and take a closer look at some halogen-free control cables from HELUKABEL.

1. Control cables for indoor and outdoor uses

Indoor control cables are used to transmit control signals to mechanical equipment in buildings, factories, and plants, providing high-speed and reliable data transmission. They are an essential component of modern infrastructure, ensuring efficient communication networks in various environments.

Outdoor control cables are designed to withstand harsh environmental conditions and ensure uninterrupted signal transmission. The use and installation of outdoor control cables must account for environmental factors such as rainfall, UV rays, impact, and corrosion resistance. Additionally, considerations must be made for fluctuating temperatures and humidity levels typically encountered outdoors.

>>See more: Some types of control cables from HELUKABEL

>>See more: Identify the quality of control cables

2. Which criteria should control cables for outdoor use meet?

Control cables for outdoor use should meet the following criteria:

2.1 Conductor material

Electric cables are made of metal, which is an excellent conductor of electricity. The type of metal used in the conductor significantly affects the suitability of the control cable for outdoor use. Copper is the most popular choice for control cables and power cables for its excellent electrical conductivity and resistance to corrosion.

Aluminum is also a viable option for electrical cables, but it does not conduct electricity as well as copper and can oxidize over time. Therefore, aluminum cables are typically used for shorter periods or in applications where corrosion resistance is more critical than conductivity.

2.2 Resistant to harsh environmental conditions

Electrical cables are typically insulated with one of three common materials: PVC, polyethylene (PE), and cross-linked polyethylene (XLPE). PVC is the most popular insulation type due to its durability and resistance to sunlight and moisture. However, PVC is less flexible than polyethylene, making it less suitable for use in cold weather. Polyethylene offers greater versatility, with excellent resistance to moisture and chemicals. XLPE, while the most expensive, is also the most durable and can withstand extreme temperatures.

When selecting control cables for outdoor use, it is crucial to consider the specific environmental conditions. For example, cables exposed to sunlight should have UV-resistant insulation. Similarly, if the cable is used in wet environments, it is important to choose cables that are water-resistant.

>>See more: Top 3 types of cables for the steel industry

2.3 Efficiency of control cables

Control cables used outdoors need to withstand higher voltages and currents than those used indoors. The cable size must match the required capacity. Undersized cables cannot handle the load, leading to reduced cable life and posing risks of fire and explosion. Conversely, oversized cables result in unnecessary waste. Accurate calculation of cable size based on current and conductor length is essential to ensure safety and performance.

>>See more: Control cables versus electric cables

3. A glance at halogen-free control cables

3.1 What are halogen-free control cables?

Elements such as fluorine, chlorine, bromine, and iodine are halogens and are found in group 17 of the periodic table. These elements are present in many chemical compounds, such as polyvinyl chloride (PVC). PVC is highly durable, making it a common material for various technical products, including insulation and sheathing materials in cables.

Halogen-free control cables do not contain any halogens in their composition. Compared with PVC control cables, halogen-free cables offer several advantages in the event of fire:

- Halogen-free cables do not release toxic or corrosive gases during a fire, reducing the threat to humans.

- In contrast, when plastics containing halogens burn, the halogens are released into the air and can combine with water to form acids that are toxic to humans.

- Halogen-free control cables can also be used at higher temperatures than PVC cables.

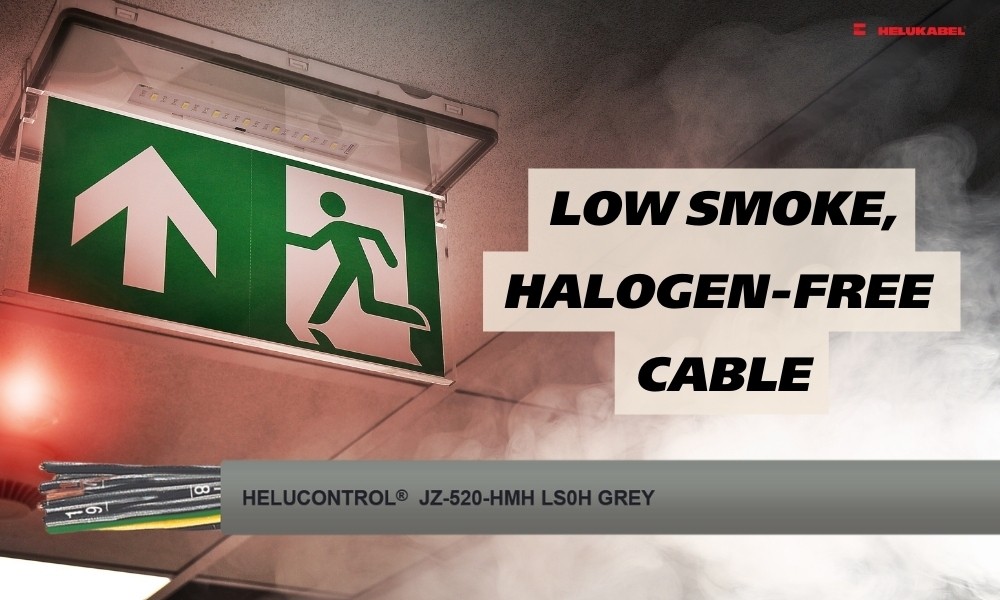

3.2 Low smoke, zero halogen (LSZH) control cables

"Low smoke" and "halogen-free" are two terms that are often combined to describe a particular line of cable that possesses both characteristics. Here is the difference between these two:

- Low smoke: Emits only a thin, clear smoke, assisting firefighters and evacuation efforts by maintaining visibility of emergency exits. However, low-smoke cables are not necessarily halogen-free.

- Halogen-free: Does not contain fluorine, chlorine, bromine, iodine, or other halogens. While halogen-free cables are safer in terms of toxicity, they may emit thicker smoke, which can reduce visibility.

3.3 Applications of halogen-free cables

Halogen-free control cables are increasingly used in various fields and environments, including the following:

- Telecommunications: Halogen-free control cables are used for both indoor and outdoor applications. Their low smoke and non-toxic properties make them effective in environments where fire safety and air quality are critical.

- Public spaces: These cables are heavily used in hospitals, schools, airports, and metro systems. In such environments, managing safe evacuation during an emergency is of paramount importance.

- Residential and commercial buildings: Halogen-free control cables are a safer alternative for wiring in these settings. Their use is becoming more popular in new construction and renovation projects that prioritize sustainability and user safety.

- Electric vehicles: Halogen-free control cables help reduce vehicle weight and improve safety. They are integral to wiring, battery systems, and various electrical components.

- Industrial applications: Halogen-free cables are common in automation, control systems, and mechanical devices. Factories increasingly focus on minimizing environmental impact while ensuring their electrical systems are safe and reliable.

3.4 Standards for halogen-free control cables

Halogen-free control cables complying with relevant standards are not necessarily completely halogen-free. To qualify as halogen-free, cable lines must ensure they do not exceed certain values. The key standards include:

- IEC 60754-1 or DIN EN 60754-1: This standard defines the test equipment and procedure for determining the amount of halogen acid gas formed when burning materials in cables and insulation sheath.

- IEC 60754-2 or DIN EN 60754-2: This standard describes the determination of acidity by measuring pH and conductivity values.

- DIN EN 61034-2: This standard defines a method for measuring the smoke density of burning cables under specified conditions.

4. Top 4 types of halogen-free control cables for outdoor use

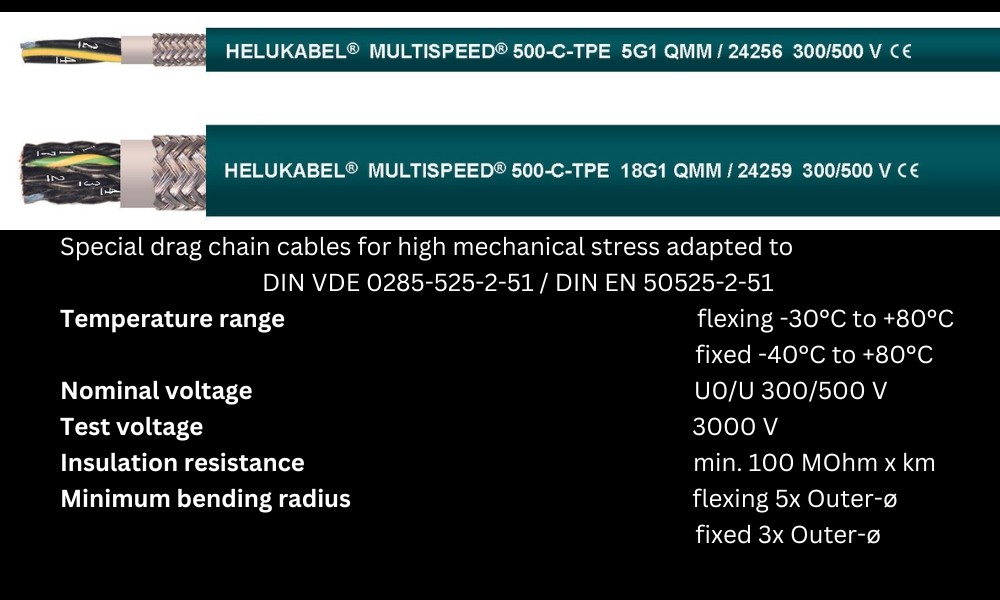

4.1 MULTISPEED® 500-C-TPE control cable

MULTISPEED® 500-C-TPE halogen-free control cable is made from TPE material with the following outstanding properties:

- High property of alternating bending strength.

- Long life durability due to low friction-resistance.

- Low adhesion, high tensile strength, abrasion- and impact resistance at low temperature.

- The outer sheath is made from TPE, making it suitable for installation in harsh conditions: oil resistance, chemical resistance, tear resistance, UV and ozone resistance.

With the above advantages, the application range of this cable line is extremely diverse:

- For moving applications in drag chains for long distances, high and low speed of movements.

- These cables are installed in dry, moist, and wet rooms and in the open air with free movement without tensile stress or forced movements.

- These robust and abrasion resistant special control cables are used in applications where permanent stresses appear in energy drag chains.

- These cables are installed everywhere, where high requirements for flexibility, abrasion, oxygen and chemical resistance are necessary.

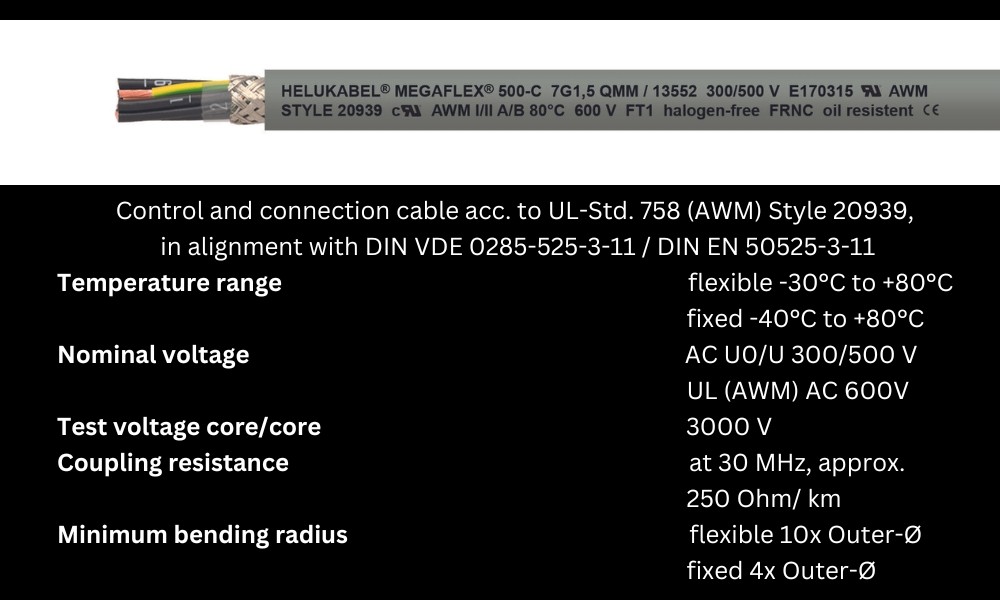

4.2 MEGAFLEX® 500-C control cable

MEGAFLEX® 500-C control cable is highly flexible. Beside halogen-free property, this cable line exhibits the following characteristics:

- EMC-preferred type: braided screen of tinned copper wires, approximately coverage 85%.

- Resistant to oil, UV radiation, ozone, weathering effects, hydrolysis, greases, abrasion.

In terms of application, MEGAFLEX® 500-C control cable can be used for fixed installation or flexible applications with non-recurring free movement, without forced movement control and without tensile stress, for heavy mechanical load in dry, damp, and wet rooms as well as outdoors. In addition, this can be used as a connecting and control cable in machine and plant construction, HVAC technology, warehousing and materials handling technology, shipbuilding, renewable energy sector such as wind turbine construction.

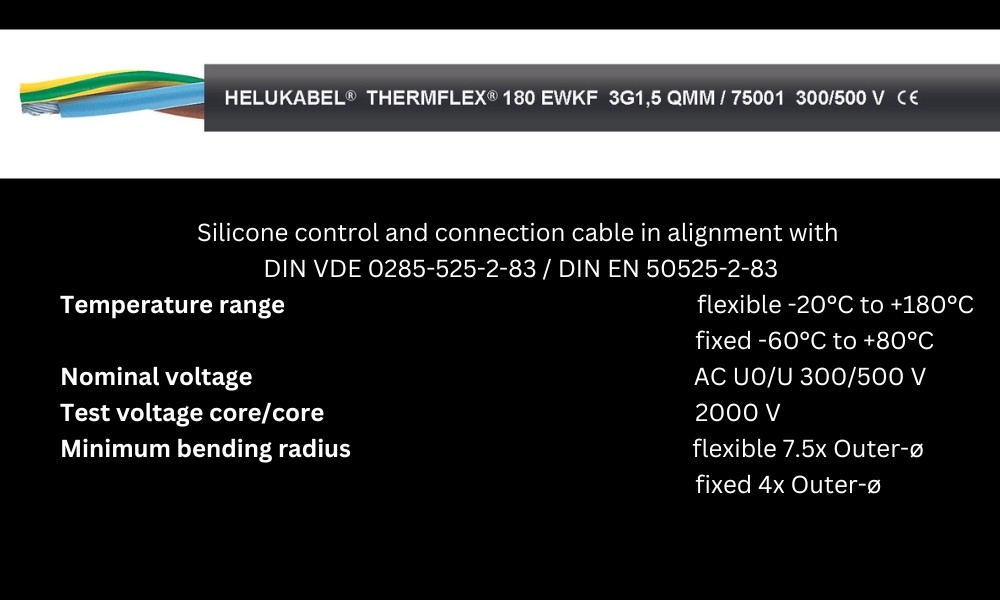

4.3 THERMFLEX® 180 EWKF control cable

This is a line of temperature-resistant control cables made of silicon, with enhanced mechanical strength, and possesses the following outstanding features:

- Resistant to ozone, oxygen, weathering effects, alcohols, dilute acids, alkalis, saline solutions, oxidizing agents, high molecular weight oils, vegetable and animal fats, plasticisers and clophen, seawater.

- Abrasion-resistant, notch-resistant, tear-resistant.

- Higher mechanical resilience, increased abrasion resistance and longer service life than conventional silicone cables due to EWKF quality.

- High flash point.

- Leaving an insulating layer of SiO2 when exposed to flames.

- No significant changes in dielectric strength and insulation resistance even at higher temperatures.

Halogen-free silicone cable THERMFLEX® 180 EWKF is used for applications that require an increased mechanical strength as well as a higher temperature resistance, for use in dry, damp, and wet rooms as well as outdoors. They are also suitable for use in air conditioning and heating systems, in saunas and solariums, in foundries, in steel, cement and ceramic plants as well as in furnaces and lighting fixtures.

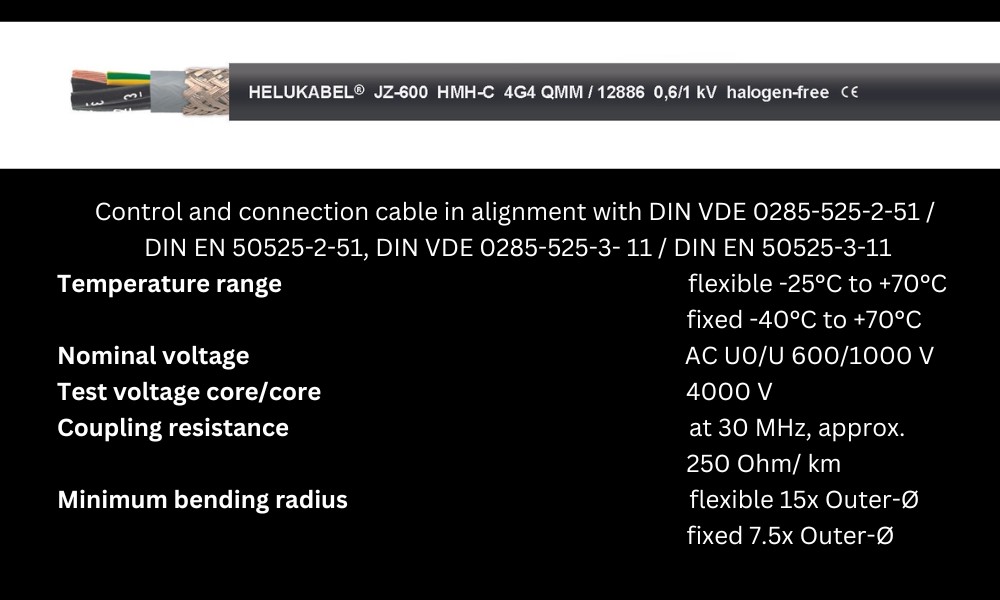

4.4 JZ-600 HMH-C control cable

JZ-600 HMH-C is highly flame-retardant, largely resistant to oil. This type of cable is suitable for use in tool machinery, conveyor belts, production lines, plant construction, in air-conditioning devices, in metallurgical, steel and rolling mills. For fixed installation and flexible applications with occasional, not constantly recurring free movement without forced motion, without tensile stress and for medium mechanical stress.

If you still have any concerns or questions, don't hesitate to reach out to HELUKABEL Vietnam's engineering team promptly for detailed assistance.

HELUKABEL® Vietnam

905, Nguyen Kiem Street, Ward 3, Go Vap District, Ho Chi Minh City 700000, Vietnam

Tel. +84 28 77755578 | info@helukabel.com.vn | www.helukabel.com.vn