What is IP rating? IP-rated cables for harsh environments

Electrical cables and cable accessories that meet IP67 and IP68 standards are selected for use in harsh environments, providing protection for electrical equipment against the ingress of liquids and solids in exposed conditions.

Contents:

1. Impacts of harsh environments on electrical systems

2. What is IP rating? IP rating for harsh environments

3. Choosing products with the appropriate IP rating for specific environments

4. IP-rated cables and accessories for harsh environments

4.1 IP-rated electrical cables

4.2 Cable glands

4.3 HELUTEC cable connectors

1. Characteristics of harsh environments

1.1 What is a harsh environment?

A harsh environment can include various conditions that may cause significant damage to electrical systems if they are not properly designed. Environmental factors such as extreme high or low temperatures, sudden temperature fluctuations, dust, humidity, moisture, and even salt mist can have a major impact. Additionally, real-world application factors may include vibration, impact, high pressure, corrosive chemicals, and different types of electrical stress.

Even when equipment is housed in a fully sealed enclosure, cable connectors can still be entry points for dust, moisture, or other contaminants, leading to damage to internal components. Therefore, selecting the right cables and cable accessories that can withstand harsh environments is crucial.

1.2 Impacts of harsh environments on electrical systems

- Extreme temperatures: Most failures in electronic equipment due to environmental factors result from excessively high or low temperatures, as well as sudden temperature fluctuations. These conditions create thermal stress due to differences in the thermal expansion coefficients of various materials.

- Vibration and impact: Vibration and impact are unavoidable in many harsh environments, such as in the transportation industry or industrial machinery. These forces can cause cracks in solder joints, loosening of screws, or the failure of assembled components.

- Explosion risk: Industries such as oil and gas, coal mining, and wood processing facilities often have environments filled with highly flammable materials like gases, vapors, dust, or fine powders. In such conditions, even a small spark can trigger a serious explosion.

- Chemical corrosion: In many harsh environments, high humidity combined with salt mist is a common cause of connector corrosion. Additionally, exposure to industrial chemicals such as acids (sulfuric, chromic, acetic, hydrochloric, hydrofluoric acids) or bases (ammonium, potassium, sodium hydroxides) can severely damage electronic components and connectors. Therefore, selecting corrosion-resistant materials and fully sealed designs is crucial in these environments.

2. What is the IP rating?

Meaning of 2 digits in IP rating

2.1 Meaning of the IP rating

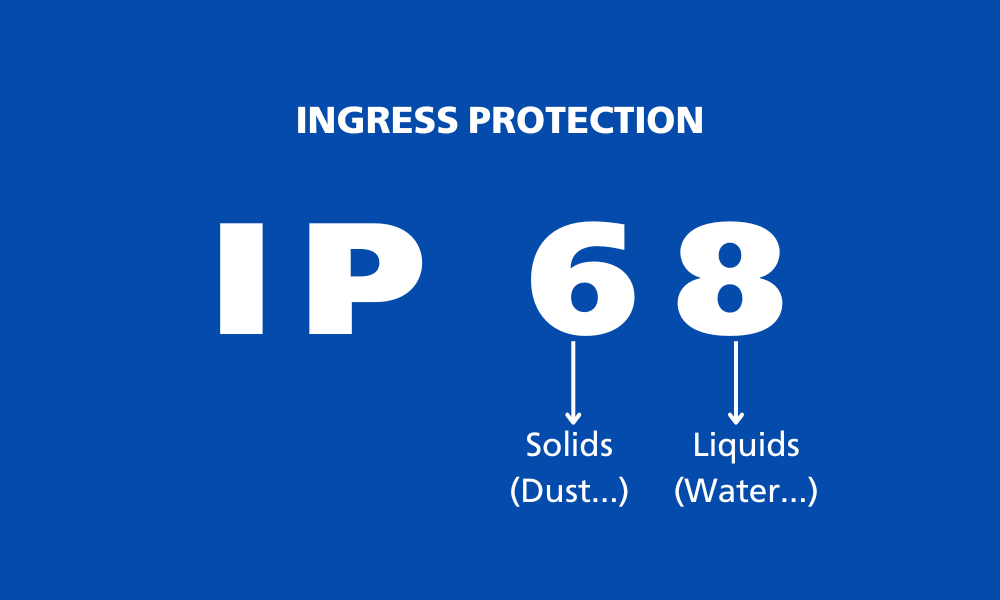

The IP (Ingress Protection) rating system uses a two-digit code to define a product’s level of protection against the intrusion of solid particles (such as dust) and liquids (such as water). The appropriate IP rating for a product depends on the level of exposure to dust or water during operation. To ensure reliability, it is essential to select an IP rating that can withstand the worst possible conditions the equipment might encounter.

IP ratings are defined by the IEC 60529 standard, which evaluates the protection level of enclosures (including connectors) against dust and liquid ingress. This standard is also recognized in the European Union (EU) under the designation EN 60529.

The IP rating consists of two digits:

- The first digit: Indicates the level of protection against solid objects and dust.

- The second digit: Indicates the level of protection against water and other liquids.

IP ratings cover a range of protection levels, from resistance to water splashes to the ability to withstand prolonged submersion. Components and equipment with higher waterproof ratings typically also offer better dust protection.

2.2 Common IP standards for harsh environments

Electronic devices used in harsh environments, such as the marine industry, typically require an IP65 rating or higher to withstand extreme weather conditions. Systems that demand high reliability often need an IP66 rating or above to ensure resistance against medium-pressure water jets or temporary submersion in shallow water.

Summary of suitable IP ratings for electronics in harsh environments:

| IP | Protection level |

| IP65 | Resistant to water jets from all directions and low-pressure water sprays |

| IP66 | Resistant to high-pressure water jets |

| IP67 | Can withstand immersion in water up to 1 meter for 30 minutes |

| IP68 | Can withstand prolonged immersion in water |

Devices with IP6X ratings provide maximum dust protection and are designed for durability in extreme conditions.

3. Choosing products with the appropriate IP rating for specific environments

When selecting electrical cables and connectors with an IP rating, the first step is to assess the worst-case exposure to dust and moisture that the product might encounter. Additionally, some environments have unique factors that must be considered when designing cable connectors, depending on the substances the system may come into contact with.

Below are some common environments where IP-rated cables and accessories are required:

3.1 Marine environment

Electrical cables used in offshore applications or aboard ships should have a minimum IP64 rating to prevent water spray from penetrating and causing moisture-related damage. However, for better protection, IP67-rated products are recommended, ensuring resistance to temporary submersion in shallow water.

For marine environments where equipment might be submerged for extended periods, IP68-rated products are the ideal choice, as they ensure the device remains operational even after being retrieved from deep water without water ingress.

3.2 Industrial environments

Depending on the type of equipment used in industrial environments, electrical cables and connectors with an IP65 rating or higher are necessary. This ensures protection against high-pressure water jets from multiple directions, even though full submersion resistance may not always be required.

Additionally, IP65-rated connectors typically offer excellent dust protection, which is crucial in factories and manufacturing environments where airborne dust and contaminants are common.

3.3 Outdoor electrical equipment

Most outdoor electrical equipment requires a minimum IP65 rating to ensure stable operation. Two common examples include: lighting systems and security devices. For higher durability and reliability, IP66 or IP67-rated products are the optimal choice, as they provide enhanced protection against harsh weather conditions.

4. IP-rated cables and accessories for harsh environments

At HELUKABEL, we provide a wide range of electrical cables and accessories with various IP ratings to meet different application needs. Some of our featured products include:

4.1 IP-rated electrical Cables

Depending on the specific application environment, customers can choose from HELUKABEL's IP-rated cables, including:

- Tauchflex-FL and Tauchflex-R cables: Featuring EPR rubber insulation and outer sheath, these cables can be submerged in water at depths of up to 300 meters.

- HELUPOWER® SOOW and HELUPOWER® SJOOW cables: Designed for power supply applications, these cables are commonly used in cranes, lifting equipment, and construction machinery.

- HELUPOWER® H07RN-F LS0H cable

- HELUPOWER® AQUATIC-750-BLUE cable

Additionally, HELUKABEL offers waterproof DC cables, such as the HELUPOWER® SOLARFLEX®-X PREMIUM , which is specifically designed for floating solar power projects.

4.2 IP68-rated cable glands

Most of HELUKABEL’s cable glands are IP68-rated, ensuring high performance and reliability in harsh environments. These cable glands provide superior protection against dust and water ingress, making them ideal for demanding industrial and outdoor applications.

| IP68 – 5 bar | IP68 – 10 bar |

| HELUTOP® HT-MS, HELUTOP® MS-EP brass cable gland | HSK-MS-PVDF brass cable gland |

| HELUTOP® MS-EP4 EMC brass cable gland | HSK-MZ-E EMC brass cable gland |

| HELUTOP® HT-MS-EX-d / e4 explosion-proof cable gland | HSK-MS-EX explosion-proof cable gland |

| PA HELUTOP® HT plastic cable gland | PA HSK plastic cable gland |

| HELUTOP® HT-E, HELUTOP® HT-Clean stainless steel cable gland | HSK-INOX Clean stainless steel cable gland |

| HELUTOP® Easy threadless cable gland |

>>Find out more: Brass cable glands for harsh environments

HELUTEC cable connectors

4.3 IP68-rated cable connectors

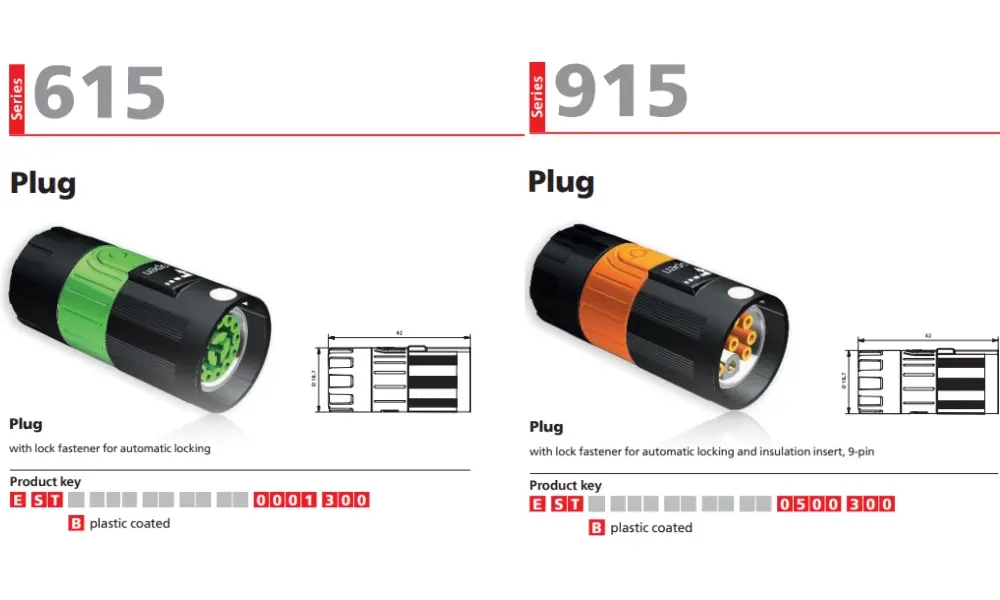

In addition to IP68-rated cables and cable glands, HELUKABEL’s HELUTEC® cable connectors are designed to resist water jets and temporary submersion. Each cable assembly, including the connector and cable, meets IP66/IP67 standards. For special applications, such as environments exposed to water or steam, these connectors can be certified up to IP69K.

The HELUTEC® 615/915 series is specifically designed for long-term underwater operation. Testing has shown that even after continuous submersion for 120 hours at a depth of 15 meters under 1.5 bar pressure, these connectors continue to function normally. As a result, both series are IP68-certified for maximum protection in harsh conditions.

If you still have any concerns or questions, don't hesitate to reach out to HELUKABEL Vietnam's engineering team promptly for detailed assistance.

HELUKABEL® Vietnam

| Address | 905, Nguyen Kiem Street, Ward 3, Go Vap District, Ho Chi Minh City 700000, Vietnam |

| info@helukabel.com.vn | |

| Hotline | +84 28 77755578 |

| Website | www.helukabel.com.vn |

| Discover our products and place orders | Tiki | Product finder |

| Follow us on | Facebook | LinkedIn | Instagram | Youtube | Zalo | WhatsApp | Tiktok | Spotify |