What are servo motors? How do they work and their applications?

Servo motors are used as actuators in automatic control systems. Let’s explore the basic information about this type of motor!

1. Overview of servo motors

1.1 What is servomechanism?

A servo mechanism, also known as a servo system and commonly referred to as a “servo” is an automatic control system capable of adjusting its output based on feedback received. This allows it to achieve exceptional precision in controlling the position, speed, and overall motion of an object. Fundamentally, a servo mechanism is a feedback control system comprising a sensor, a controller, and an actuator:

- Sensor: Measures the position or speed of the object and sends this information to the controller, where it is processed to determine the necessary adjustments.

- Actuator: Typically, a servo motor executes these adjustments to align the actual output with the desired output.

The outstanding feature of a servo mechanism is its ability to correct errors in real time. This is achieved through negative feedback, where the system continuously compares the desired action with the actual action and minimizes the error between them. This ongoing adjustment process enables the servo mechanism to maintain precise control over the systems it governs, making it an indispensable component of modern technology.

1.2 What are servo motors?

A servo motor is an integral part of a servo system. It is a type of rotary or linear motor that receives power from a servo amplifier and generates torque or force to act on a mechanical system, such as an actuator or brake.

Servo motors enable precise control of parameters like angular position, acceleration, and speed. They operate within a closed-loop control system, where the current output is monitored and adjusted to achieve the desired state. In this system, control actions are based on the motor's output, employing positive feedback to regulate movement and the final position of the motor shaft.

Servo motors provide high flexibility in manufacturing environments. Typical applications include collaborative robots (cobots), conveyors, automatic doors, CNC machines, radar systems, tracking systems, and various automation systems.

1.3 Structure and operating principles of servo motors

A servo motor is composed of two windings:

- Stator: Wrapped around the fixed part of the motor, also known as the motor's magnetic field winding.

- Rotor: Wrapped around the rotating part of the motor, also referred to as the motor's armature winding.

The motor includes two bearings at the front and rear to allow the shaft to rotate freely. An encoder, integrated with a proximity sensor, is used to determine the motor's rotational speed and the number of revolutions per minute (RPM).

Servo motors operate within a closed-loop system, receiving commands from the servo controller and utilizing feedback devices to close the control loop. Together, the motor, controller, and feedback device form a servomechanism. The controller sends commands to the motor, causing it to move. The encoder provides feedback (such as current, speed, or the motor's current position) to the controller. The controller compares the feedback data with the command parameters and adjusts the motor's operation as needed to maintain precision.

2. Classification of servo motors

Servo motors utilize two types of electrical current: AC and DC. AC servo motors are capable of withstanding higher surge currents and are commonly used in heavy industrial machinery. DC servo motors, on the other hand, are well-suited for smaller applications, offering superior control and feedback capabilities.

3. Applications of servo motors

Compact and efficient, yet servo motors play a crucial role in applications requiring precise position control. They are widely used in tasks that demand high-accuracy repetitive operations:

- Robots: Servo motors are used to initiate motion and position robotic arms at precise angles.

- Conveyor belts: Servo motors control the movement of conveyor belts, allowing products to pass through various production stages and stop or start at exact points, such as during labeling, bottling, or packaging processes.

- Cameras: Integrated into cameras to adjust lenses and improve focus, reducing image blurriness.

- Automatic doors: Operate automatic doors in supermarkets, hospitals, and cinemas.

- Textile industry: Control knitting machines, looms, and machines for spinning or weaving fabrics.

- Solar tracking systems: Used to adjust the tilt angle of solar panels, ensuring they remain aligned with the sun.

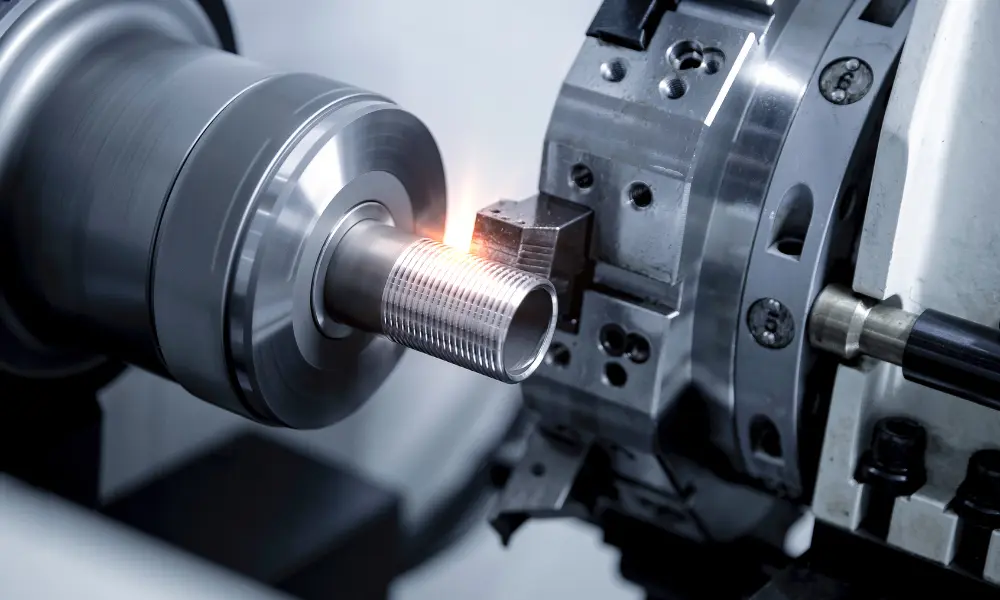

- Metalworking machines: Provide precise motion control for milling, cutting, and other metalworking equipment.

4. Servo motor cables

4.1 The role of cables in servo motors

Servo motor cables are specialized cables used to transmit power and control signals between servo motors and controllers or actuators. They ensure continuous electrical signal transmission, supporting precise control of position, speed, and torque in servo motor systems.

Servo motor cables are designed to withstand constant movement and harsh operating conditions commonly found in industrial automation and robotics applications. These cables not only ensure signal stability but also provide high durability and reliable performance in complex environments.

4.2 Types of cables used for servo motors

The types of cables used for servo motors include:

- Power cables: Used to transmit the electrical energy required for the servo motor. These cables typically have a larger cross-section to ensure they can carry sufficient current to meet the motor's operational demands.

- Feedback cables: Connect the servo motor to feedback devices, enabling real-time monitoring of parameters such as position, speed, and motor operating status for closed-loop control.

- Control cables: Transmit control signals and connect the servo motor to the controller.

5. HELUKABEL’s servo motor cables

5.1 TOPFLEX motor cables

TOPFLEX motor cables play a critical role in signal transmission. These cables help maintain seamless connectivity between components in the production line, ensuring the stable operation of machinery.

| TOPFLEX motor cables | Features |

| 1. TOPFLEX®-EMV-2YSLCY-J 2. TOPFLEX®-EMV-UV-2YSLCYK-J 3. TOPFLEX®-EMV-UV-3-PLUS-2YSLCYK-J 4. TOPFLEX®-EMV-3-PLUS-2YSLCY-J 5.TOPFLEX®-EMV-UV-3-PLUS-2YSLCYK-J UL/CSA 6. TOPFLEX®-EMV-UV-2YSLCYK-J UL/CSA 7. TOPFLEX®-EMV-UV-2YSLC11Y-J UL/CSA | These cables are used as connection cables for applications with medium mechanical stress, suitable for fixed installations and occasionally for free movement in dry, damp, or wet environments, as well as outdoor settings. They can be directly buried starting from sizes of 4G16 mm² and above. These cables are ideal for use in industries such as automotive, food processing, packaging, chemical, and environmental technology. |

| 8.TOPFLEX®-EMV-UV-2XSLCHK-J 9.TOPFLEX®-EMV-UV-3-PLUS-2XSLCYK-J 10. TOPFLEX®-EMV-UV-3-PLUS-2XSLCHK-J 11.TOPFLEX®-EMV-UV-3-PLUS-2XSLCYK-J UL/CSA 12. TOPFLEX®-EMV-UV-2XSLCYK-J | These cables are used for inverter systems, ensuring electromagnetic compatibility (EMC) in systems and installations, as well as in equipment and machinery that may emit electromagnetic interference (EMI) that could negatively affect the surrounding environment. |

| 13. TOPFLEX®-MOTOR-EMV 3/3 | Triple screened. Applications include machine tools, processing and manufacturing machinery, machining centers, industrial robots, conveyor systems… |

| 14. TOPFLEX®-MOTOR-EMV 103 | Well-suited for SIMOVERT control devices in industrial applications such as pumps, fans, conveyor systems, air conditioning systems, and similar uses. |

| 15. TOPFLEX® 600 VFD 16. TOPFLEX® 650 VFD | TOPFLEX® 600 VFD (PVC outer sheath) and TOPFLEX® 650 VFD (TPE outer sheath) are screened, oil-resistant |

| 17. TOPFLEX® 600-C-PVC 18. TOPFLEX®-PVC 19. TOPFLEX® 600-PVC 20. TOPFLEX® 302-UL 21. TOPFLEX® 611-C-PUR 22. TOPFLEX® 611-PUR 23. TOPFLEX®-PUR 24. TOPFLEX®-302 | Some other servo motor cables are made from various materials such as PVC, PUR, and TPE. They feature some characteristics such as anti-interference, oil resistance, abrasion resistance, and compatibility with drag chains |

5.2 TOPSERV servo cables

TOPSERV servo cables meet the standards and requirements of manufacturing plants in automated production lines. Depending on the specific cablé, they offer distinct characteristics and applications tailored to various needs.

| TOPSERV servo cables | Features |

| These are highly flexible servo motor cables, compatible with drag chains. Typical applications include machinery manufacturing, plant construction, robotics, automation, drive engineering, control systems, and production. They are especially suitable for mechanical engineering and export systems. |

| Made from special PVC, designed for applications involving fixed installations or non-continuous movement |

| PUR servo cable with 1 or 2 signal pairs 0.6/1kV, highly flexible, cable for drag chain |

| The supply conductors for these cables are ideally combined with the control conductors for the brake function and the transmission of the Sick Hiperface DSL protocols |

| TOPSERV® 650 VFD | Highly flexible, extremely oil-resistant motor supply cable for modern servomotors |

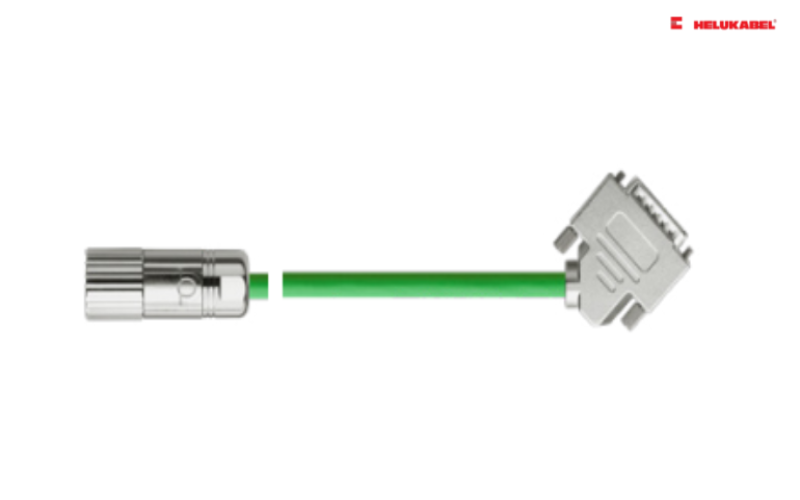

5.3 TOPGEBER feedback cables

Servo motor feedback cables include:

- TOPGEBER 512 PUR: Encoder cable suitable for cable drag chain systems.

- TOPGEBER 511 PVC: Encoder cable designed for applications with minimal movement or fixed installations.

- Incremental Feedback Cable

- Tachofeedback Cable: Helps adjust motor speed and measure actual values.

- Incremental Feedback Cable-C-PUR: Provides acceleration or position feedback for control signal transmission during positioning tasks. It also serves as a flexible connection cable for tachometers, brakes, and pulse generators under high mechanical stress in factories, machinery, and control systems. It can be used in dry, damp, and wet environments.

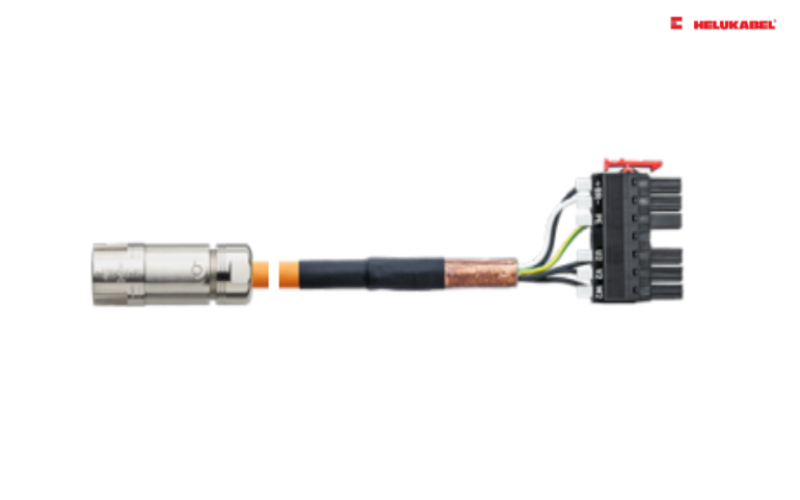

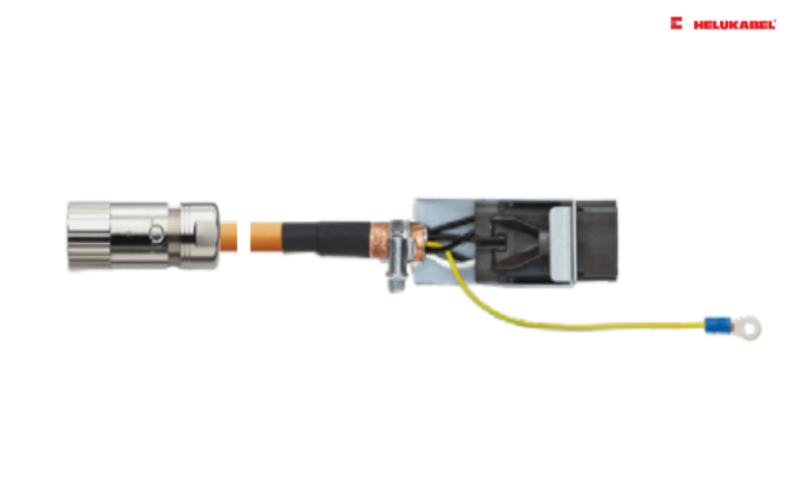

5.4 Harnessing cables for servo motors

In addition to cables, HELUAKBEL also provides harnessing solutions for drive motors using two common materials, PVC and PUR. These solutions are compatible with various OEMs, including Siemens, Lenze, Bosch Rexroth, Rockwell/Allen-Bradley, and B+R Automation…

If you still have any concerns or questions, don't hesitate to reach out to HELUKABEL Vietnam's engineering team promptly for detailed assistance.

HELUKABEL® Vietnam

| Address | 905, Nguyen Kiem Street, Ward 3, Go Vap District, Ho Chi Minh City 700000, Vietnam |

| info@helukabel.com.vn | |

| Hotline | +84 28 77755578 |

| Website | www.helukabel.com.vn |

| Discover our products and place orders | Tiki | Product finder |

| Follow us on | Facebook | LinkedIn | Instagram | Youtube | Zalo | WhatsApp | Tiktok | Spotify |