What are water-resistant cables and their importances?

Water-resistant cables prevent the penetration of water and moisture, which cause damage to the cables. Let’s explore the basic information about water-resistant cables in this article!

Contents:

1. What are water-resistant cables?

Water-resistant cables or water-blocking cables are specially designed to withstand challenges related to moisture, ensuring reliability and efficiency in conditions where standard electrical cables might fail. Applications exposed to water are often harsh and can affect cable performance, so these specialized water-resistant cables are manufactured to endure various external factors and maintain functionality at different depths. These cables are designed to prevent water from penetrating and damaging the cable's insulation, ensuring the cable operates effectively and durably in wet conditions.

There are two main ways water or moisture can infiltrate electrical cables:

- Radial ingress: Water or moisture enters the cable through gaps in the sheath or protective layers, or through any breach in the cables. Once water gets inside the cables, it travels longitudinally within the cables.

- Longitudinal ingress: Water penetrates the cable through improperly constructed joints or terminations, inefficient end caps, especially when joint pits are flooded. This may occur during installation, maintenance, or when the cable is placed near high-moisture areas.

2. Water-resistant cables – solutions for various applications

2.1 Applications of water-resistant cables

Water-resistant cables are essential for environments with a risk of exposure to moisture, such as:

- Food processing plants, where frequent cleaning and sterilization with hot steam are required.

- Outdoor applications like solar power systems, which are regularly exposed to rain and harsh environmental conditions. In particular, water-resistant cables are an indispensable component of floating solar power systems, which are becoming increasingly popular.

- Marine and offshore applications with harsh conditions, such as on ships, oil rigs, or port facilities.

- Underground applications, such as in infrastructure projects, where cables are buried.

2.2 Water-resistant cables ensure high durability

Water-resistant cables, depending on their AD level, can withstand and ensure durability for various applications. This is especially useful for applications like floating photovoltaic systems or installations in areas prone to flooding, heavy rainfall, or high humidity, without concerns about electrical cable failures. This durability provides long-lasting performance, minimizing the need for frequent replacements or repairs.

Water contact with cables can pose serious risks, including corrosion of components and potential system failures. When moisture, whether from the air or direct contact, interacts with metal parts such as electrical conductors, it can cause rust. This corrosion not only weakens the system’s integrity but also increases the likelihood of failures.

2.3 Resistance to environmental effects

In addition to water resistance, electrical cables with a high AD rating, such as AD8, are also capable of withstanding environmental impacts. AD8-rated water-resistant cables are designed to resist UV radiation, extreme temperatures, and wear and tear caused by the environment. This is crucial for maintaining the long-term performance and safety of the system.

2.4 Water-resistant cables ensure fire safety

Moisture also increases the risk of electric shock and short circuits. Water is an excellent conductor of electricity, and when it penetrates electrical systems, it poses a significant danger to user safety. Even a small amount of moisture can damage insulation, leading to exposed wires and increasing the risk of electric shock if touched.

Moreover, when water accumulates in the gaps between conductors, it can cause short circuits by bridging connections that are meant to be separated. This can result in equipment failure and, in severe cases, may lead to fire and explosions. Therefore, taking preventive measures and using water-resistant cables is essential for maintaining the safety and reliability of electrical systems.

2.5 Water-resistant cables ensure compliance with industry standards

Water-resistant cables are manufactured to meet stringent international standards for safety and performance. This ensures they are suitable for use in a wide range of solar energy systems, from small residential setups to large solar farms. Using cables that comply with these standards helps solar installers and operators meet regulatory requirements and guarantees long-term reliability for their systems.

3. Classification of water-resistant cables

AD is a classification system for electrical cables, indicating the level of moisture resistance of the cable. The UNE 20460-3:1996 standard defines the protection levels of AD. Below are some examples of AD protection levels:

| Level | Description | Applications |

| AD1 – Negligible | The possibility of water presence is negligible. | Locations where walls typically show no signs of water, but brief exposure may occur, such as in the form of steam, and where good ventilation ensures rapid drying. |

| AD2 – Drops | Possibility of vertical water drops | Locations where steam occasionally condenses into water droplets or where steam may occasionally appear. |

| AD3 - Sprays | Possibility of water droplets falling at angles greater than 60° from vertical. | Locations where water spray forms a continuous film on walls and/or floors. |

| AD4 – Splashes | Possibility of water splashes from all directions. | Locations where equipment may be exposed to water splashes; applies to certain types of lighting and construction site equipment. |

| AD5 – Jets | Possibility of water jets from all directions. | Locations where water from hoses is frequently used, such as car wash stations and patios. |

| AD6 – Waves | Possibility of exposure to sea waves. | Coastal areas like wharf, beaches, and quays. |

| AD7 - Immersion | Possibility of temporary water immersion, either partially or fully. | Locations prone to flooding and/or equipment being submerged in water. Water levels may reach up to 150 mm above the highest point of the equipment, with the lowest point not more than one meter below the water surface. |

| AD 8 -Submersion | Possibility of permanent and complete water submersion. | Locations like swimming pools, where electrical equipment is completely and permanently submerged in water. |

4. Waterproof connectors – indispensable parts

In an electrical system, it is crucial not only for each individual component to withstand the effects of moisture and water, but also for the connection points to be waterproof. These connection points are where electrical current or data transfers from one component to another, making them critical areas within the system. In all cases, the contact points within electrical connectors must remain dry, as moisture can lead to dangerous short circuits. Therefore, waterproof connectors must also be capable of preventing water ingress.

The IP (Ingress Protection) rating is a standard that helps users easily select appropriate waterproof connectors for their applications. Connectors with high IP ratings provide protection against dust, immersion in water, and high-pressure water jets. Different IP protection levels are defined based on operational conditions related to exposure to dust, short-term or long-term immersion in liquids, and contact with high-temperature water or steam.

5. HELUKABEL’s water-resistant cables

The water-resistant cables from HELUKABEL meet various standards and are suitable for a wide range of applications.

5.1 Water-resistant cables for photovoltaic systems

Some water-resistant DC cables for photovoltaic systems include:

- SOLARFLEX®-X H1Z2Z2-K: This cable meets the standards DIN VDE 0285-525-2-21 / DIN EN 50525-2-21 Appendix E and the TÜV Rheinland standard. Notably, this cable can be directly buried.

- HELPOWER® SOLARFLEX®-X H1Z2Z2-K UL cable: This cable is designed for various applications and complies with UL standards.

- HELPOWER® SOLARFLEX®-X PREMIUM cable: This cable features enhanced water resistance and meets the TÜV 2 PfG 2750 standard, making it particularly suitable for floating solar applications.

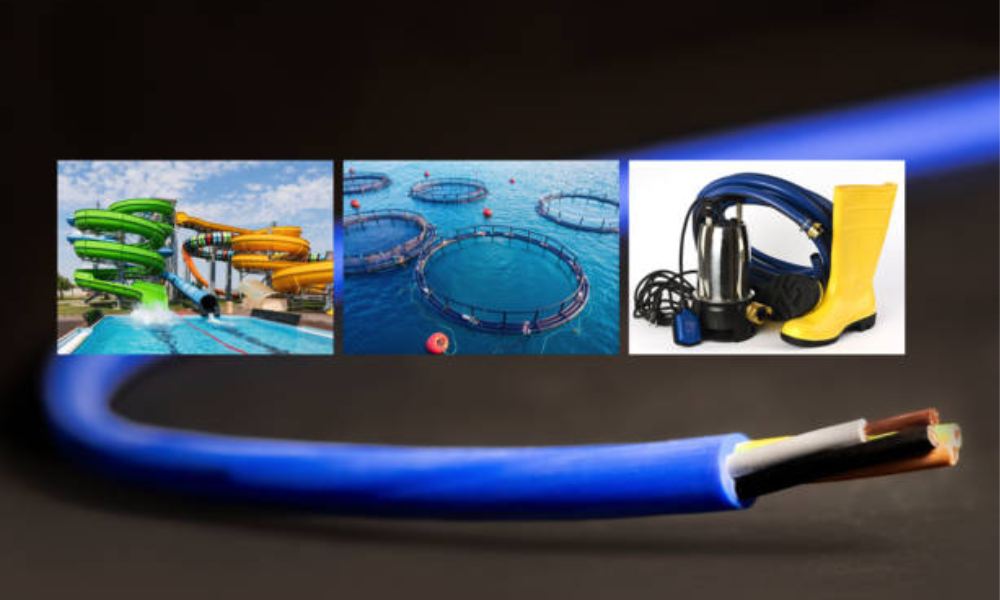

5.2 HELUPOWER® AQUATIC-750-BLUE water-resistant cables

HELPOWER AQUATIC-750-BLUE cables are designed to operate at a voltage of 450/750 V while maintaining excellent performance even when used in underwater environments. With a protective sheath made from a special cross-linked compound, this cable is durable in potable water, seawater, and chlorinated water environments at depths of up to 600 meters.

A notable feature of the HELPOWER AQUATIC-750-BLUE cables is that they have been approved according to the KTW BWGL standard, which evaluates plastic and organic materials in contact with drinking water. This ensures hygienic safety for the cable and is further supported by the W270 approval from the German Gas and Water Association. Additionally, the cables meet the necessary drinking water standards in Italy and Poland through certifications DM 174 and PZH.

5.3 Tauchflex-FL and Tauchflex-R water-resistant cables

The insulation and outer sheath of Tauchflex-FL and Tauchflex-R water-resistant cables are made from EPR. These cables are specifically designed for use as connecting and control cables for submersible motor pumps, underwater floodlights, and float switches, demonstrating exceptional reliability even when submerged in potable, treated, and domestic water at depths of up to 300 meters.

They are effective for installations in dry, damp, and wet areas, as well as outdoor environments. However, these cables are not suitable for hazardous areas, which is an important limitation to keep in mind depending on your application.

5.4 HELUPOWER® SOOW water-resistant cables

The HELUPOWER® SOOW water-resistant cables feature insulation made from EPR rubber, and an outer sheath constructed from CPE rubber. These cables are specifically designed for use as a supply cable in industrial plants and processing facilities. It is suitable for cranes, hand lamps, lifting equipment, construction machinery, and motors, ensuring reliable performance in various demanding environments.

6. Customer Story: Sun Signature Show

With its long coastline, many Vietnamese companies have leveraged this advantage to develop projects near the sea. Due to the specific environmental conditions of these installations, the cables used must meet two basic requirements:

- Resistant to saltwater corrosion, ensuring they withstand the high salinity of the marine environment.

- Stable signal transmission in underwater installation environments.

This was the challenge faced by one of our customers at HELUKABEL Vietnam for their Sun Signature Show project. To address the customer’s concerns for this project, we recommended and supplied the HELUPOWER AQUATIC-750-BLUE water-resistant cable. This cable resolved two major issues for the project:

- It performed well in water, ensuring the signal transmission remained stable and accurate.

- The cable was designed to withstand seawater salinity levels up to 3.5%, while the actual salinity level at the project site was only 3.2%.

>>Find out more: Sun Signature Show

If you still have any concerns or questions, don't hesitate to reach out to HELUKABEL Vietnam's engineering team promptly for detailed assistance.

HELUKABEL® Vietnam

| Address | 905, Nguyen Kiem Street, Ward 3, Go Vap District, Ho Chi Minh City 700000, Vietnam |

| info@helukabel.com.vn | |

| Hotline | +84 28 77755578 |

| Website | www.helukabel.com.vn |

| Discover our products and place orders | Tiki | Product finder |

| Follow us on | Facebook | LinkedIn | Instagram | Youtube | Zalo | WhatsApp | Tiktok | Spotify |