Cables used in mining industry

What role does the mining industry play in the industrial sector? What type of electrical cable ensures safe, continuous, and durable operation in mining activities? Let’s explore in the following article!

1. What is the mining industry?

Mining is the process of extracting valuable materials from beneath the Earth’s surface. Commonly mined materials include coal, gold, and iron ore. Among these, iron ore is the raw material used in the production of iron metal.

These economically valuable substances extracted from the Earth are known as minerals. Minerals are typically inorganic substances with specific chemical compositions and distinct crystalline structures. While minerals can be valuable in their pure form, in nature, they are usually mixed with other rocks and unwanted materials.

During mining, this mixture of rocks and minerals is extracted together from the mine and then processed and refined to separate the desired minerals. This is a crucial step in producing the final products used in various industries and daily life.

Typically, three main stages occur at an active mining site:

- Extraction: Using open-pit or underground mining techniques to bring mineral materials to the surface.

- Initial processing: Sorting raw materials and separating valuable minerals from waste rock (known as tailings).

- Mineral processing: Crushing, grinding, smelting, or refining minerals into final products ready for market.

Mining plays a vital role in providing raw materials for energy production, construction, and essential minerals for electronics and many modern consumer goods.

2. The roles and benefits of the mining industry

The mining industry, including coal mining, plays an incredibly important role in modern life as it provides the raw materials for nearly every aspect of human activity. From building homes and infrastructure to manufacturing electronics and renewable energy technologies - all rely on resources extracted from the Earth.

- Economic impact: Mining is a major pillar of Vietnam’s economy, significantly contributing to GDP and national revenue. For example, the Vietnam National Coal - Mineral Industries Group (TKV), a key state-owned enterprise, not only generates substantial income but also maintains coal and mineral exports to bring in foreign currency. In January 2025 alone, TKV recorded revenue exceeding VND 12,200 billion.

- Social impact: Mining operations create many jobs for local communities. In 2019, the mining sector in Vietnam employed nearly 1.1 million workers, helping to improve livelihoods and reduce poverty sustainably. Additionally, from 2012 to 2020, mining companies contributed over VND 126 billion to support local development.

- Technological advancement: The adoption of modern technologies in mining has increased operational efficiency and reduced environmental impact. At major sites like the Ha Lam coal mine (Quang Ninh), TKV has implemented automated systems, which significantly improve labor productivity and environmental protection. This reflects the industry’s commitment to sustainable, modern, and eco-friendly development.

3. Types of mining

The two most common types of mining are surface mining and underground mining.

3.1 Surface mining

This is a mining method in which the entire ore body is extracted from the surface of the Earth. Depending on the type of rock, different techniques are applied: for hard rocks such as coal or diamonds, the open-pit mining method is commonly used; whereas for softer rocks like limestone, open-cast mining is more appropriate. After extraction, minerals are separated from other rocks at processing facilities near the mine site.

However, surface mining often has a significant environmental impact on the landscape - both at the extraction site and at nearby waste disposal areas.

3.2 Underground mining

This method involves extracting minerals through deep tunnels or shafts while leaving the surface land largely unaffected. The process begins with development mining, where layers of rock are removed to create access paths closer to the ore body. This is followed by production mining, during which the ore containing the desired minerals is brought to the surface.

In underground mining, health and safety are of paramount importance. Effective ventilation systems and stable, reinforced tunnels are essential to protect workers and ensure long-term mining operations.

4. Characteristics of machinery and equipment used in the mining industry

The mining industry, including coal mining, relies on large and complex machinery to support various stages of mineral extraction and processing. These machines are designed to handle heavy-duty operations and optimize efficiency throughout the mining workflow:

- Dragline excavators and bulldozers are used for removing the overburden (layers of soil and rock that cover the mineral deposit).

- Drilling machines are deployed to place explosives, while excavators and specialized dump trucks handle the transportation of ore and waste rock.

- Sorting equipment such as vibrating hoppers and trommel screens help separate ore from unwanted materials.

- In underground mining, elevators are used to transport workers in and out of the mine, as well as to lift extracted ore from deep underground to the surface.

As the demand for mineral resources continues to grow, there is increasing pressure on mining equipment to deliver higher performance and efficiency. This applies to both surface and underground mining operations.

To meet these demands, a new generation of large-scale, high-mobility machinery has emerged. Massive haul trucks and specialized cranes are used to transport huge volumes of ore and overburden. At on-site processing facilities, equipment such as crushers, reactors, ball mills, and roasters are employed to extract valuable minerals from the ore.

5. Features of cables used in the mining industry

Large-scale equipment used in the mining industry must be powered by highly flexible cables that can be coiled or extended as needed. These cables must withstand extreme operating conditions, including high humidity, extreme temperatures, intense mechanical impact, and chemical exposure.

5.1 High mechanical strength

Mining cables are often subject to harsh physical conditions - they may be dragged along rough terrain, exposed to sharp surfaces, or crushed by heavy machinery. Therefore, mechanical durability is a top priority. These cables must offer high tensile strength, resistance to extreme temperatures, and protection against oil, water, chemicals, and abrasion.

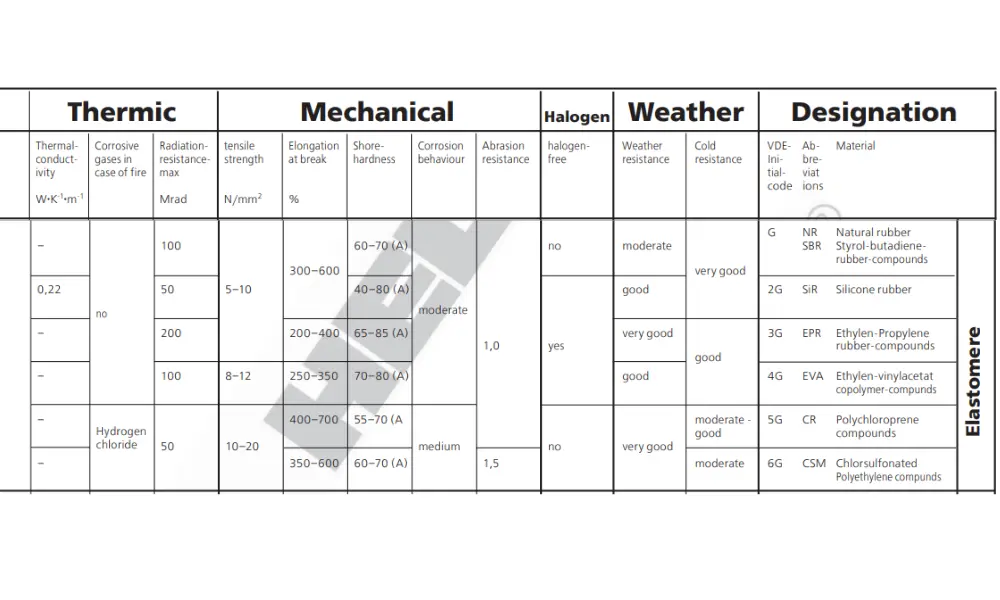

Cables with high-quality rubber or thermoplastic insulation materials are ideal for such demanding conditions, providing long-lasting performance in harsh mining environments.

5.2 High flexibility

In mining operations, cables frequently need to bend around tight spaces or move with mobile equipment. The more flexible a cable is, the easier it is to install and operate, especially in dynamic applications. Cables featuring stranded soft copper conductors and rubber insulation offer excellent flexibility, minimizing the risk of damage from bending or stretching.

5.3 Fire-resistant properties

Safety is a critical concern in mining environments. Electrical cables must comply with strict fire safety standards, especially in enclosed underground spaces. Fire-resistant cables are designed to limit flame propagation and emit low levels of smoke and toxic gases in the event of a fire. These features help protect workers' lives and maintain visibility during emergency evacuation.

Cables with low-smoke, halogen-free sheaths and high dielectric strength under fire conditions are essential for meeting safety requirements.

5.4 Resistance to harsh weather conditions

Mining operations often take place in harsh weather environments - with high humidity, temperature fluctuations, exposure to water, UV radiation, ozone, or chemicals. Therefore, mining cables must have excellent waterproofing, UV resistance, and ozone resistance to ensure long-term insulation integrity. Cables capable of stable performance in wet or corrosive environments reduce the risk of short circuits or electrical failures, contributing to continuous and safe mining operations.

6. HELUKABEL’ cables and accessories for mining industry

6.1 Intrinsically Safe (IS) cables

Intrinsically Safe (IS) cables are specially designed to prevent the generation of sparks or heat strong enough to cause ignition, even under fault conditions or abnormal operating scenarios. These cables are typically used in hazardous environments where there is a high risk of fire or explosion, such as underground mines, chemical plants, or areas with flammable gases. Some examples of Intrinsically Safe cables from HELUKABEL include:

- OZ-BL

- OZ-BL-CY: EMC-preferred type

- OB-BL-PAAR-CY: EMC-preferred type

6.2 Cables for constantly moving applications in the mining industry

HELUKABEL offers a wide range of cable solutions for various mining applications.

- Torsion cables: HELUKABEL ROBOFLEX

- Reeling cables: NSHTÖU, cáp trailing (N)SHTÖU-V, cáp trailing TROMMPUR®-H

- Flat cables: PVC-flat, PVC-flach-CY, NEO-flach, NEO-flach-C

- Lift cables: TRAGO / Lift-2S, LIFT-TRAGO®-30 / -60, NEOPREN

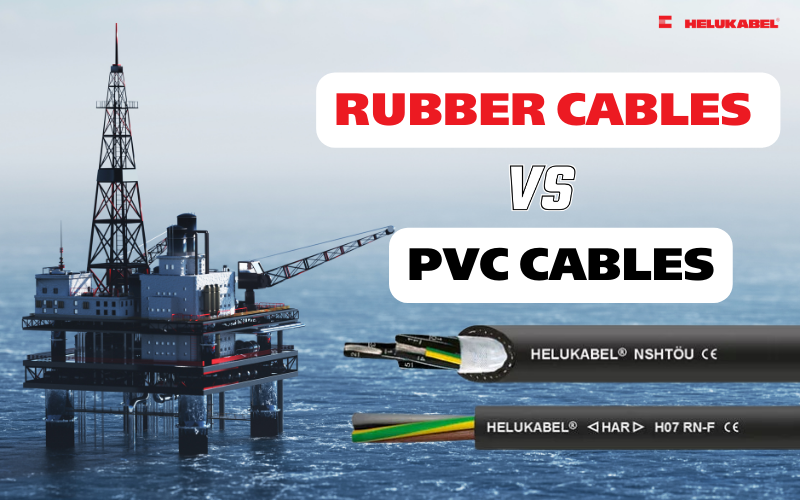

6.3 Rubber cables

The durability and mechanical resilience of rubber make it particularly well-suited for applications exposed to high mechanical stress in the mining industry. Notable rubber cable products from HELUKABEL include: NSSHÖU, HELUPOWER® SJOOW, HELUPOWER® SOOW, YELLOWFLEX

6.4 Explosion-proof cable glands

In Europe, equipment used in potentially explosive environments must comply with the ATEX Directive, which outlines technical requirements to ensure safe operation in areas with flammable gases. Additionally, the International Electrotechnical Commission (IEC) provides IECEx certification standards for equipment used in hazardous environments. These standards ensure that the equipment is designed and tested for safe use in dangerous zones, such as mining operations or petrochemical refineries.

HELUKABEL offers a range of explosion-proof brass cable glands that meet both ATEX and IECEx standards. Notable products include: HSK-MS-EX-E, HSK-MS-EX, HELUTOP® HT-MS-EX-d / e4, HELUTOP® HT-MS-EX-d 1 EMV

If you still have any concerns or questions, don't hesitate to reach out to HELUKABEL Vietnam's engineering team promptly for detailed assistance.

HELUKABEL® Vietnam

| Address | 905, Nguyen Kiem Street, Ward 3, Go Vap District, Ho Chi Minh City 700000, Vietnam |

| info@helukabel.com.vn | |

| Hotline | +84 28 77755578 |

| Website | www.helukabel.com.vn |

| Discover our products and place orders | Tiki | Shopee | Lazada | Product finder |

| Follow us on | Facebook | LinkedIn | Instagram | Youtube | Zalo | WhatsApp | Tiktok | Spotify |