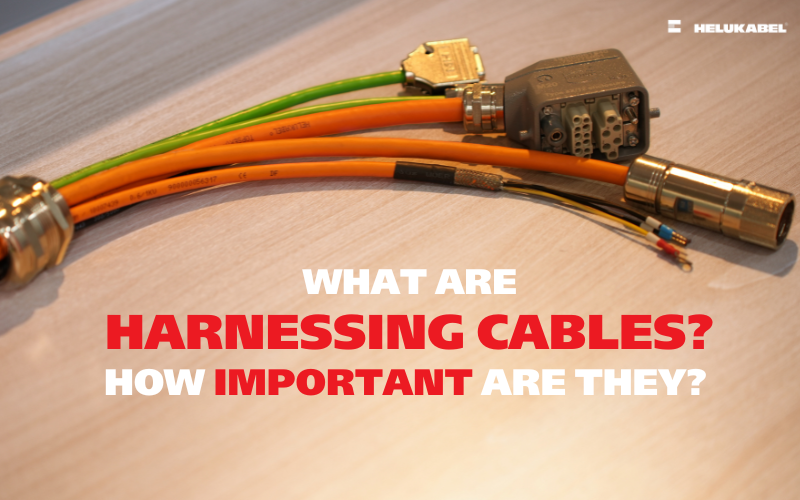

3 steps to choose harnessing cables for drive motors

Using harnessing cables offers many benefits. However, determining the right harnessing solution for your application requires careful consideration. Here are three important steps to follow.

1. Determine the purpose of use

Before proceeding with a harnessing design request, the first step is to determine the specific application and the purpose of using harnessing cables.

Harnessing cables are used across many industries to optimize the transmission of electricity or signals, or both. These cables are crucial in the production of household appliances, medical devices, electronic equipment, telecommunications, military applications, aerospace, automotive manufacturing, robotics, etc.

The design of harnessing cables varies depending on the industry. A harnessing cable can include dozens of cables with multiple components, each going in different directions with various terminals on each branch. Therefore, determining the purpose of use is essential to initially shape the design of harnessing cables.

2. Evaluate application conditions

The second factor is the environmental conditions of the application. This criterion helps determine the appropriate components for harnessing cables. In most cases, you should consider the following two factors:

1. Will the harnessing cables be used indoors or outdoors?

2. Will the harnessing cables be exposed to moisture, liquids, or chemicals?

With this information, specialized engineers can recommend suitable materials and characteristics for the outer sheath, shielding layers, wire cores, etc., ensuring optimal performance in specific environments.

3. Choose components for harnessing cables

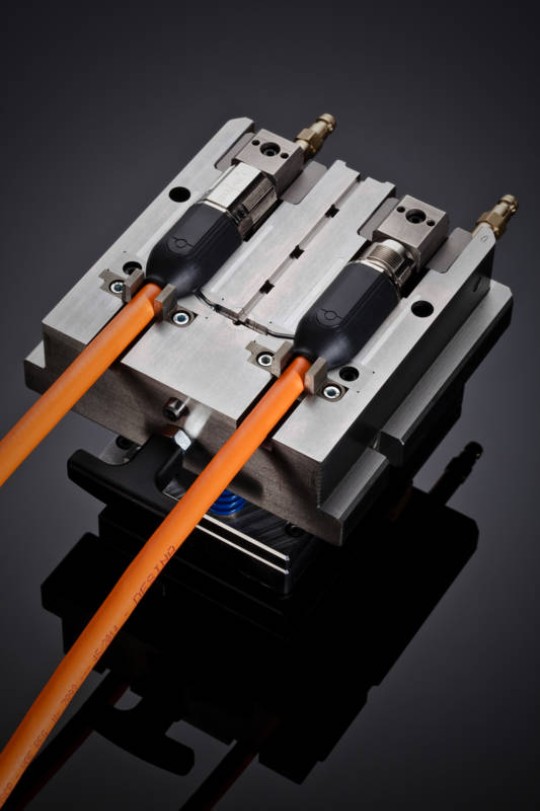

Typically, a harnessing cable consists of cables, connectors, terminals, strain reliefs and grommets. Choosing components is an extremely important step in ensuring you have a product that meets design standards and performs efficiently.

3.1. Cables

Cable is a core component in harnessing cables. When selecting cables, you need to pay attention to two major criteria: the conductor and the insulation.

Conductors are responsible for transmitting current or signals within a harnessing cable. Their transmission capacity must not exceed the voltage or bandwidth limits to avoid thermal shock or degradation. Copper is the best metal for conductors due to its excellent conductivity. However, since copper is prone to corrosion, it is essential to understand the environmental conditions to which cables will be exposed to determine the appropriate sheath.

Meanwhile, the insulation protects inner conductors from adverse conditions such as chemical exposure, oil leakage, water, humidity, and temperature variations. Common insulation materials for cable sheaths include PVC, PE, XLPE, and rubber.

3.2. Connectors

In a harnessing cable, you will find a variety of connectors used to link different cables. Some are fixed to the system, while others are removable for portable products or those with interchangeable parts.

3.3. Terminals

A terminal is the point where a cable ends, is connected to another component or is simply capped. Its role depends on its installation location and usage.

3.4. Strain reliefs

Harnessing cables are designed to be flexible, but they also require rigidity at the connection points where cables meet connectors or plugs. Strain reliefs help harnessing cables withstand stress, tension, and other flexural forces, thereby maintaining the integrity of conductors and overall performance.

3.5. Grommets

Grommets are used to keep harnessing cables secure and in place. They help maintain an organized system, making installation and maintenance more efficient.

Above are some tips for choosing harnessing cables for drive motors. If you want to learn more about specific harnessing solutions for your business, please contact our engineers for more details!

HELUKABEL® Vietnam

905, Nguyen Kiem Street, Ward 3, Go Vap District, Ho Chi Minh City 700000, Vietnam

Tel. +84 28 77755578 | info@helukabel.com.vn | www.helukabel.com.vn