What are fiber optic cables and their applications?

Fiber optic cables use light to transmit signals, helping the signal travel farther at high transmission speeds. Let's explore basic information about fiber optic cables through the following article.

1. A glance at fiber optic cables in terms of structure and benefits

1.1 What are fiber optic cables?

In the signal cable transmission industry, there are two basic types of technologies, namely transmission by electricity and transmission by light. The latter is often referred to as fiber optic cables.

The core of fiber optic cables is made of glass fiber or plastic with the transmission principle being the reflection of light rays. Based on the reflection of light rays in the core of an optical fiber, light rays will be reflected when encountering a medium with a lower refractive index. The medium has a high refractive index at the core layer (fiber core). The medium has a low index in the cladding layer, also known as the reflective layer.

Optical cables will generate 3 types of reflected rays whilst working:

- Axial mode: light is transmitted along the central axis of the fiber, which is the fastest of the three types of light.

- Low-order mode: the light has the least number of reflections and the second fastest of the three types of light.

- High-order mode: the number of reflections outweighs the other two, thereby having the lowest transmission speed.

1.2 Structure of fiber optic cables

There are 5 basic components of fiber optic cables:

(1): Cores are made from glass or plastic to spread light.

(2): Cladding has the same material as the core but has a smaller refractive index and wraps around the cores to help reflect light to the cores.

(3): Coating, usually made of PVC, protects the optical fiber during the manufacturing process.

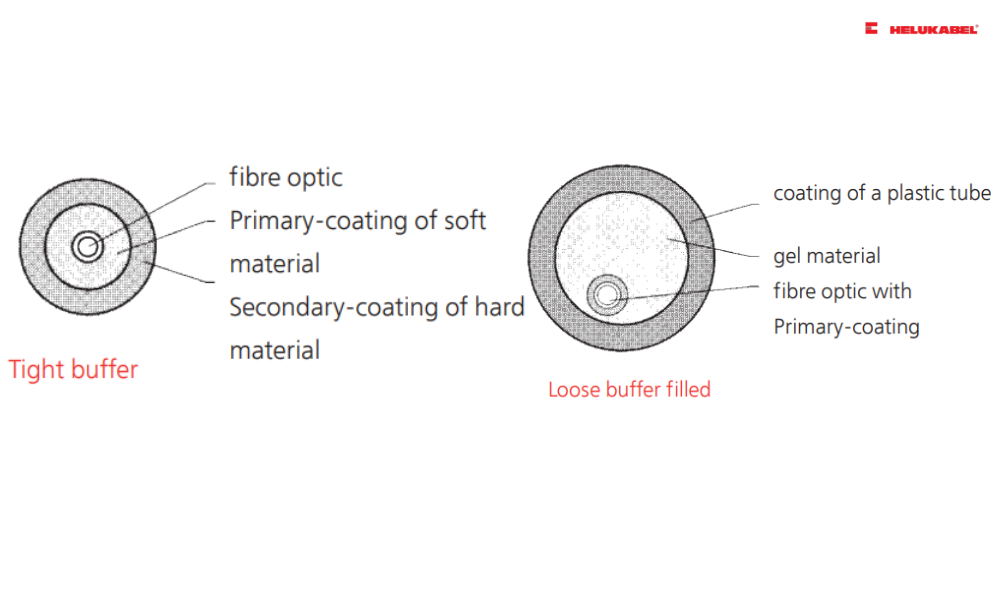

(4): Strength member is usually divided into 2 types:

- Tight buffer tube, made of flexible plastic, adheres closely to the protective shell and has a good bending radius.

- Loose buffer tube, made of a plastic tube with a diameter larger than the diameter of optical fiber, a layer of gel slime is filled to prevent this buffer tube from sticking to the protective layer. This helps the fiber inside to stretch naturally when the temperature changes.

(5): Outer jacket is a shell with impact resistance, heat resistance, tear and wear resistance, and protects the inside of optical fiber.

1.3 Benefits of using fiber optic cables

Technical infrastructure using copper cables is facing enormous challenges due to the increasing scarcity of this metal. Consequently, fiber optic cables offer a valuable alternative with numerous benefits for industries:

- Higher capacity: Fiber optic cables can carry significantly more network bandwidth than copper cables of similar thickness. Standard speeds for fiber optic cables include 10 Gbps, 40 Gbps, and 100 Gbps.

- Superior signal transmission: Light can travel much longer distances through fiber optic cables without significant attenuation, reducing the need for signal boosters. Additionally, fiber optic cables can transmit a variety of analog and digital signals.

- Reduced susceptibility to interference: Copper network cables require shielding to protect against electromagnetic interference. While this shielding helps, it is often insufficient to prevent interference when multiple cables are placed close together. The physical properties of fiber optic cables inherently avoid most of these issues.

2. Classification of fiber optic cables

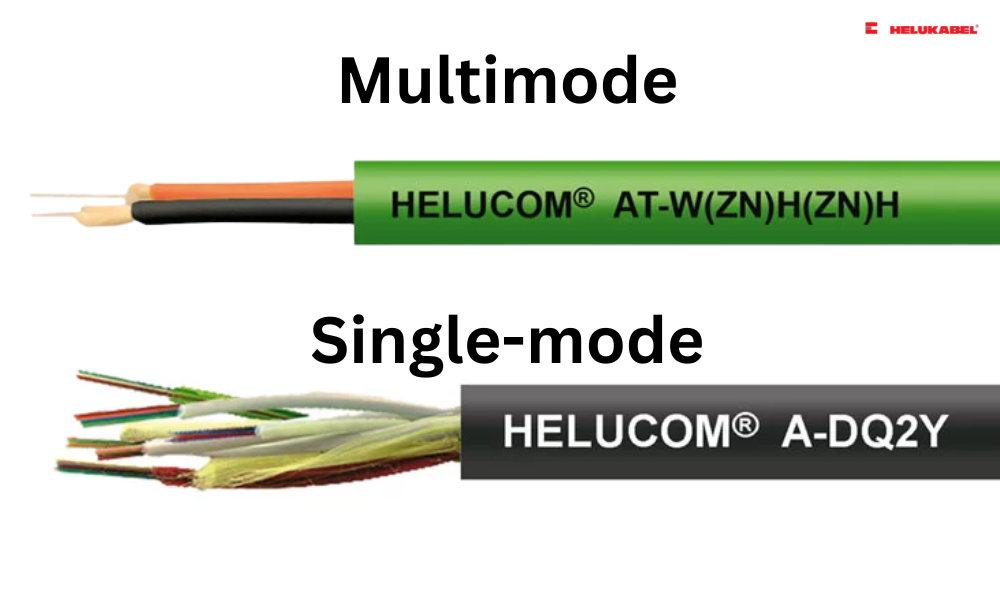

2.1 Multimode cables

Multimode is a type of fiber optic cable capable of spreading all 3 types of light rays: axial mode, low-order mode, high-order mode. Multimode is divided into 4 basic types from OM1 to OM4:

- OM1 has a core diameter of 62.5μm and a reflective layer diameter of 125μm, thereby being named 62.5/125μm.

- OM2, OM3 and OM4 all have a core diameter of 50μm and a reflective layer diameter of 125μm, so they are referred to as 50/125μm.

- The optimal operating beam wavelengths are 850 nm and 1300 nm.

The difference between OM2, OM3, and OM4 is the signal transmission speed per second and the different transmission distance. At the same wavelength of 850nm:

- OM2 has a bandwidth of 500 MHz x km.

- OM3 has a bandwidth of 1500 MHz x km.

- OM4 has a bandwidth of 3500 MHz x km.

The larger the bandwidth, the faster the signal transmission speed and the greater the transmission distance. We have the following order: OM1 < OM2 < OM3 < OM4 < OS1/OS2.

2.2 Single mode cables

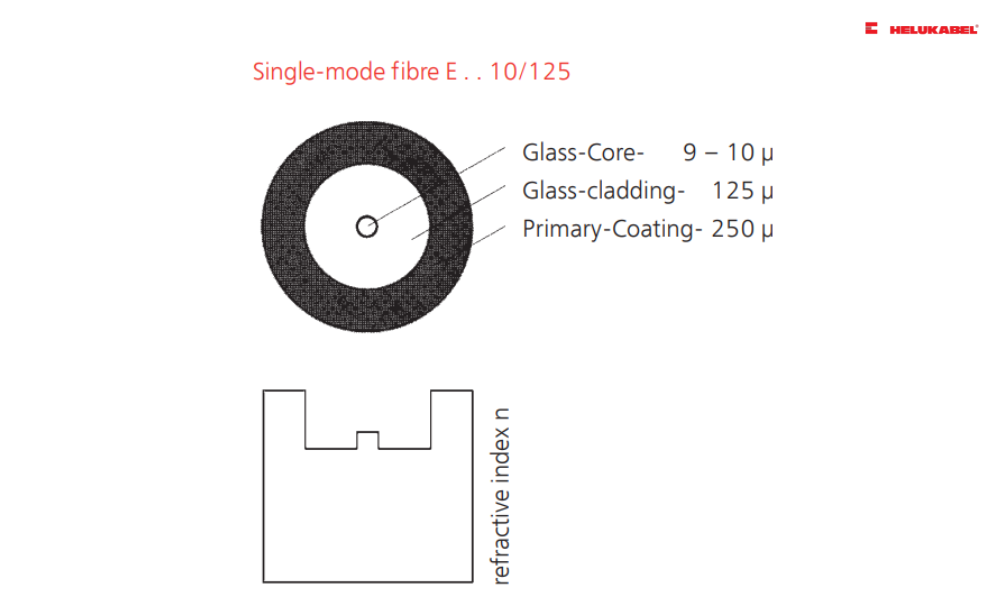

Single mode is a type of fiber optic cable that only propagates axial mode light rays.

Single mode usually has a core diameter of 9μm and a reflection layer diameter of 125μm, so it is also called 9/125μm. Optimal operating light wavelengths are: 1310 nm and 1550 nm. There are two abbreviations for single mode:

- OS1 with the protective buffer tube is a tight buffer tube.

- OS2 with the protective buffer tube is a loose buffer tube.

3. Applications of fiber optic cables

Fiber optic cables are widely used in both residential and industrial environments. In industrial settings, fiber optic cables must withstand extreme temperatures, harsh environments, and electromagnetic interference. These cables are commonly used in industrial automation applications to provide a highly reliable network system that ensures continuous production and worker safety.

Fiber optic cables are utilized in various industries, including:

- Automation: Providing reliable data transmission in industrial automation systems.

- Automotive: Used for interior/exterior lighting and signal transmission between sensors and computer equipment. These sensors, which are crucial for activating airbags, must be both fast and highly reliable.

- Heavy duty industries: Essential in sectors such as mining, which requires fault-tolerant network topologies to support people and equipment, as well as offshore drilling rigs, oil, and gas refineries.

- Power utilities

- Other fields: Used in health care, military, and defense applications…

4. HELUKABEL’s fiber optic cables

HELUKABEL's HELUCOM® fiber optic cables are manufactured according to DIN VDE 0888 standards, specifically as follows:

4.1 Industrial fiber optic cables

Industrial fiber optic cables include:

- GOF (Glass Optical Fiber) features high bandwidth and good impact resistance.

- HCS (Hard Clad Silica) is compatible with both normal mechanical and heavy-duty environments.

- POF (Plastic Optical Fiber) is used for both industrial environments and data transmission in home networks.

In addition, some fiber optic cables are highly compatible with drag chain applications such as: I-V4Y(ZN)11Y , I-V2Y, I-V2Y(ZN)11Y .

4.2 PROFIBUS + PROFInet (breakout) fiber optic cables

This is a type of fiber optic cable with many fibers, each fiber has its own jacket and then they are wrapped together. This fiber optic cable line is compatible with PROFIBUS and PROFinet communication protocols. Some typical products include:

- AT-WQ(ZN)H(ZN)B2Y fiber optic cable possesses an extremely sturdy design, suitable for use in harsh environments, can be used for direct burial.

- The AT-VYY cable line stands out with its high flexibility, not only used for fixed installation applications but can also be used for jumper cables.

- AT-W(ZN)Y(ZN)11Y fiber optic cable has a tight buffer tube structure, making the cable line easily pre-assembled. In addition, this cable line is also compatible with drag chains.

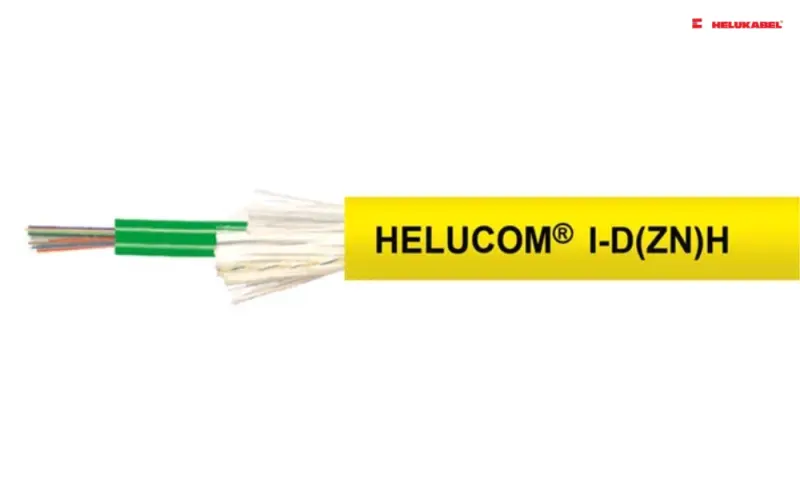

4.3 Indoor and outdoor fiber optic cables

Indoor fiber optic cables are suitable for installation in environments without strict waterproofing requirements. In contrast, outdoor fiber optic cables are designed with enhanced features to withstand environmental factors such as temperature fluctuations and UV rays.

HELUCOM I-D(ZN)H is ideal for cabling systems inside buildings. The halogen-free version of this cable is particularly suited for applications in skyscrapers, hospitals, power plants, and computer centers.

Some notable outdoor fiber optic cable products from HELUKABEL include:

- HELUCOM® I-V2Y and I-V2Y(ZN)11Y: These cables are available in two materials: PE (black sheath) and PUR (purple sheath). Their robust construction and straightforward installation make them suitable for environments that demand reliable data transmission, including heavy industrial settings.

- HELUCOM® A-DSQ(ZN)B2Y: This cable combines optical fibers with a copper core, featuring a protective shell made of PE material. It is specifically designed for fiber optic temperature measurements, such as monitoring dams. The construction of this cable meets the harsh mechanical requirements typical in these applications.

Besides, there are other fiber optic cables galore such as aerial cables, mobile fiber optic cables, multi-purpose optical cables.

4.4 Pre-assembled fiber optic cables

Besides fiber optic cables, connection equipment plays an important role in fiber optic networks. The fiber optic transmission line is only complete after installing the pigtail, jumper cable, plugs, joints, slice box, and wiring box. HELUKABEL provides pre-assembled fiber optic cable connection solutions, helping users save costs and installation time.

Some examples of pre-assembled fiber optic cables include: Patch Cables I-VH , Pigtails , Industry Plugs POF / HCS / MM .

If you still have any concerns or questions, don't hesitate to reach out to HELUKABEL Vietnam's engineering team promptly for detailed assistance.

HELUKABEL® Vietnam

905, Nguyen Kiem Street, Ward 3, Go Vap District, Ho Chi Minh City 700000, Vietnam

Tel. +84 28 77755578 | info@helukabel.com.vn | www.helukabel.com.vn