7 outstanding features of SUPERTRONIC®- 310-C-PVC cvv cable

Cvv cables are highly compatible with automation industry. Let’s explore outstanding features of a cvv cable line from HELUKABEL - SUPERTRONIC®- 310-C-PVC in this article.

1. Cvv cables and industrial automation

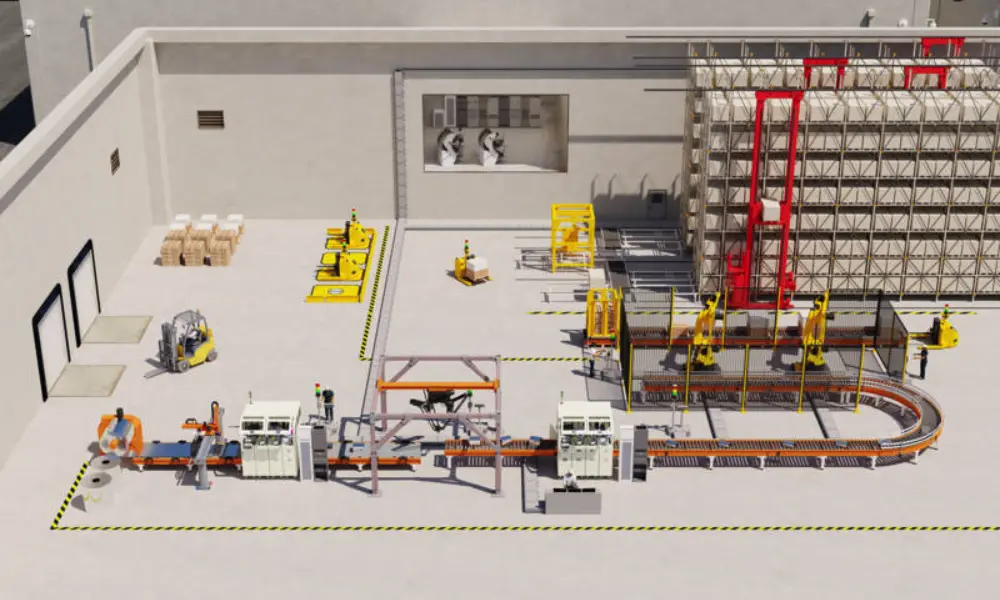

An increasing number of production processes are being automated across industries around the world; for example, the automotive industry, F&B, logistics, robotics… Computer controlled machining centers ensure greater productivity, consistent high quality and flexible manufacturing to batch size. Integrated automation systems in industry require a very large number of processors, sensors, drives and controls that are intelligently and digitally interconnected with each other. The right cables and wires are indispensable for this: they ensure that all system components reliably receive the power and data they need.

They must also meet complex requirements, depending on the application: for example, they might need to be resistant to elevated temperatures, chemicals, oil or mechanical stresses such as bending and torsion, be suitable for use in confined spaces or capable of ever higher data transmission rates. Such requirements make industrial automation a challenging environment for cables and wires.

CVV cables feature unique structural components , including an insulating sheath and an outer PVC sheath, offering high flexibility and suitability for diverse operating environments. These attributes address challenges in automation fields. Specifically, HELUKABEL's SUPERTRONIC CVV cable line is tailored with advanced features optimized for continuous motion systems. The SUPERTRONIC cable series includes variants such as:

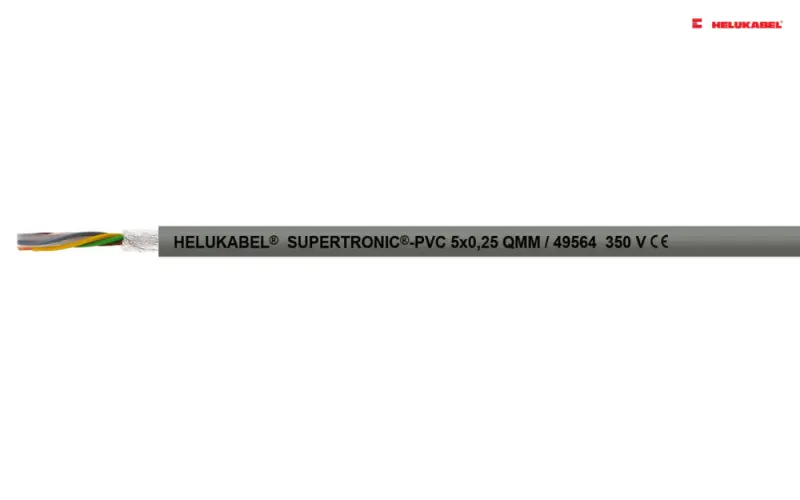

SUPERTRONIC®-PVC

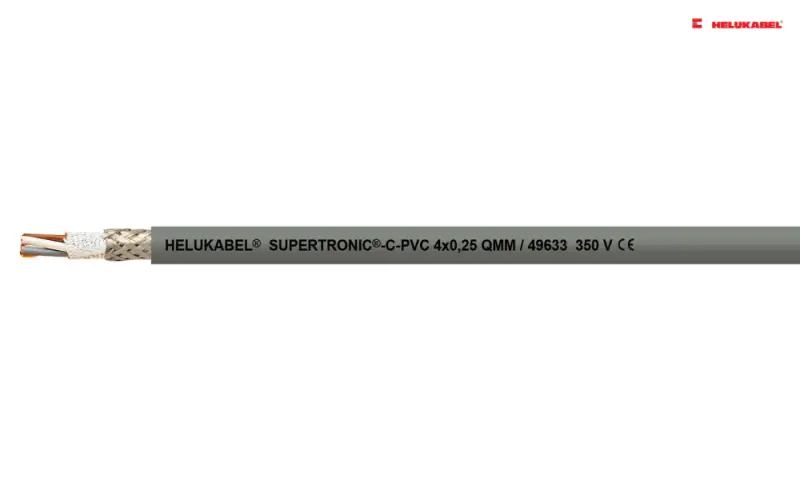

SUPERTRONIC® C-PVC

SUPERTRONIC®-310-PVC

SUPERTRONIC®- 310-C-PVC

Among them, the SUPERTRONIC®-310-C-PVC cable stands out for its exceptional characteristics.

>>See more: A glance at cvv cables and cxv cables

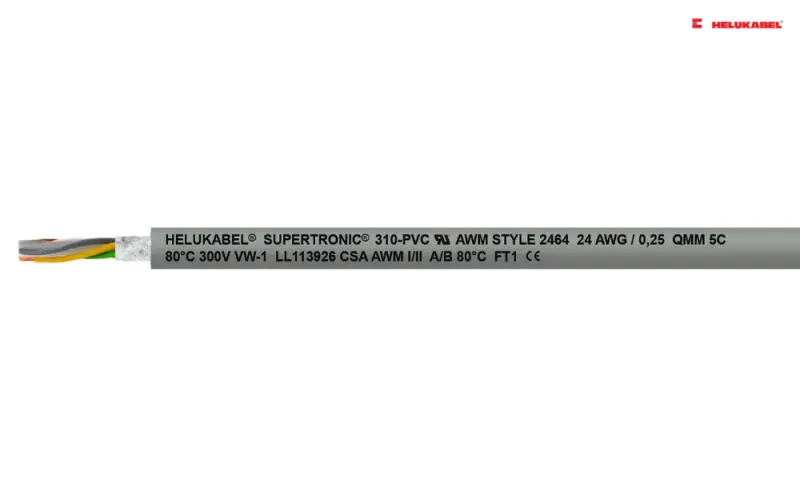

2. Structure of SUPERTRONIC®- 310-C-PVC cvv cable

The structure of the SUPERTRONIC®- 310-C-PVC cvv cable line can be divided into 4 basic elements as follows:

- Conductor: copper wire bare, finely stranded, unilay with short lay lengths. One major advantage of short lay length is the wire is highly flexible.

- Insulating sheath: special PVC according to UL-Std. 1581 Tab. 50.183 (semirigid).

- Outer sheath: grey color, made of special PVC, according to DIN VDE 0207-363- 4-1 / DIN EN 50363-4-1 (compound type TM5), UL-Std. 1581.

- Screen: braided screen of tinned copper wires, approx. coverage 85%

3. Top 7 outstanding features of SUPERTRONIC®- 310-C-PVC cvv cable

3.1 Outstanding physical characteristics

Coupling resistance is a measure of the quality of the anti-interference layer. For SUPERTRONIC®- 310-C-PVC, this cvv cable line has a coupling resistance index of 30 MHz, about 250 Ohm/km. This characteristic makes the cable particularly suitable for high-frequency applications, where noise protection and reduced signal loss are crucial factors.

Also, this cvv cable line stands out with the following voltage characteristics:

- Nominal voltage UL (AWM) AC 300 V

- Test voltage core/core: 1500 V

- Test voltage core/screen: 1000 V

- Breakdown voltage: 3000 V

These voltage ratings show that cvv SUPERTRONIC®- 310-C-PVC cables are designed to meet the high requirements for insulation, signal protection and durability in industrial and commercial environments.

3.2 Temperature spectrum up to 80 °C

Temperature range refers to minimum thresholds and maximum thresholds that the cables can operate normally. This is heavily dependent on the cores and insulating materials, which result in varying operating temperatures. Generally, the material becomes flexible at high temperatures and stiff at low temperatures, making the material less suitable for applications that involve bending at high or low temperatures.

Regarding SUPERTRONIC®- 310-C-PVC cvv cable line, the temperature is -5°C to +80°C (when flexing) and -40°C to +80°C (for fixed installation). The lowest temperature for fixed installation is up to -40°C, helping this cvv cable line withstand harsh conditions in cold environments, such as cold storage or extreme climates, without reducing performance. or durability. The ability to withstand temperatures as high as +80°C helps the cable withstand temperatures generated during operation, ensuring safety and reliability when used in industrial systems requiring high heat loads.

>>See more: Control cables for harsh conditions

3.3 Small bending radius

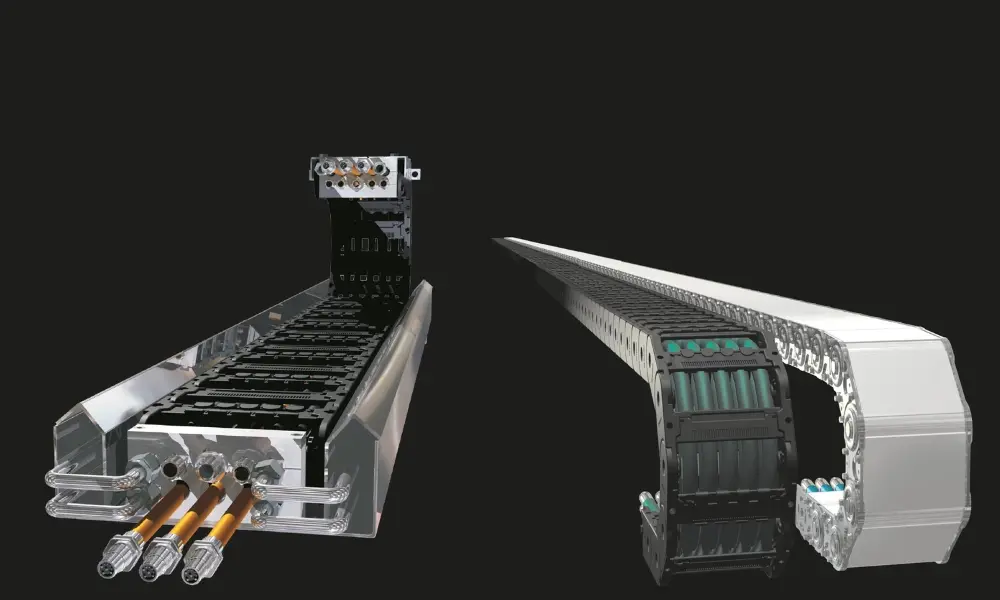

Besides high flexibility, this cvv cable line also has a small minimum bending radius; 7.5 times the diameter when flexing and 5 times the diameter for fixed installations. Thanks to that, the cable is highly flexible, easy to bend and adjust in limited spaces. This line of cables is suitable for use in applications with frequent, continuous lifting and bending stresses such as machine and tool manufacturing, robotics, drag chains, and other continuously moving applications.

3.4 Oil-resistant attributes

Oil can cause decomposition or weakening of the cable's insulation and protective sheathing materials. Oil resistance helps protect the cable from these effects, thereby increasing the service life of the cable and reducing the frequency of maintenance or replacement. SUPERTRONIC®- 310-C-PVC cvv cable line is oil-resistant according to DIN VDE 0473-811-404 / DIN EN 60811-404 / IEC 60811-404 standards, helping the cable's electrical and mechanical features to be maintained, ensuring effective signal and power transmission.

3.5 Flame-retardant capabilities

SUPERTRONIC®- 310-C-PVC is highly flame-retardant according to DIN VDE 0482-332-1-2 / DIN EN 60332- 1-2 / IEC 60332-1-2, UL VW-1, CSA FT1. Along with safety assurance, this standard renders the cable highly applicable in different industrial environments.

3.6 Small cross-sections

The cross-sections of SUPERTRONIC®- 310-C-PVC cvv cable range from 0.14mm² to 0.34mm², along with the number of cores starting from 2 to 25 cores, resulting in high flexibility, space saving, light weight, and accurate signal transmission. Thanks to these, this cvv cable line is among the top priorities for industrial applications and high technology, from automation systems to compact electronic devices.

In addition, during the production of this cvv cable line, in addition to information and symbols such as voltage, cross-section, number of cores... information about metric meter marking is also printed on the cable surface. Thanks to this information, users can easily determine the length of electric cables at certain points without using specialized cable measurement tools.

>>See more: The importance of conductor's cross-sections

3.7 Adhering to international standards

SUPERTRONIC®- 310-C-PVC cvv cable line is one of the cable lines recognized to meet many international standards of HELUKABEL. Compliance with international standards such as DIN EN, IEC, UL and CSA ensures that the cable is compliant with international safety regulations, making it easy to import and use in global industrial projects. This cable line is specially manufactured for use in the export-oriented machine manufacturing industry, especially in the US and Canadian markets.

If you still have any concerns or questions, don't hesitate to reach out to HELUKABEL Vietnam's engineering team promptly for detailed assistance.

HELUKABEL® Vietnam

905, Nguyen Kiem Street, Ward 3, Go Vap District, Ho Chi Minh City 700000, Vietnam

Tel. +84 28 77755578 | info@helukabel.com.vn | www.helukabel.com.vn

_welcome_slider.png)