Cable glands: Selection criteria and installation instructions

Cable glands are strongly associated with the cabling process and harnessing solutions. Therefore, users need to get a grasp on how to select and install cable glands for each specific application.

Cable glands play a key role in many different industries, providing a safe and reliable method for connecting and securing electrical cables to equipment. Whether you are using power cables, control cables or instrument cables, properly installing cable glands is essential to ensure safety, functionality and longevity.

>>See more: Top 4 popular cable glands

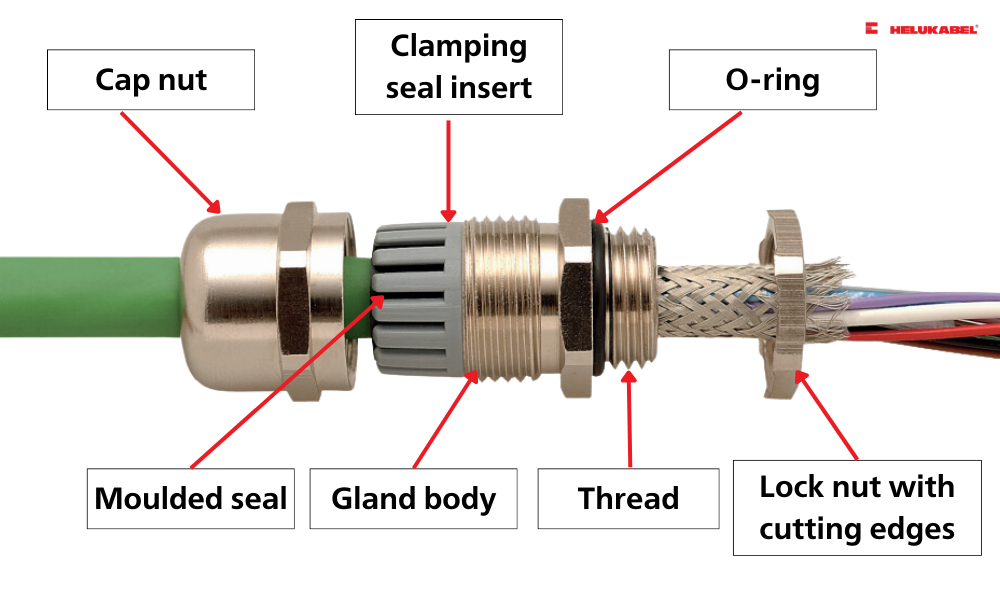

1. Structure of cable glands

Structure of cable glands

Prior to the selection of cable glands, users shall have a notion of cable glands’ basic structure. Main components of cable glands include:

- The gland body is made from various materials such as plastic, brass, stainless steel. This component constitutes the outer sheath, ensuring the structural integrity and serving as a conduit for cables to pass through.

- Cap nut is basically made of the same materials as the main body, threads onto the body, and secures the cables in place. The design of the nut consists of a series of ridges or teeth that grip the outer shell of the cable, preventing the cable from slipping out. The threaded connection between the nut and body provides a secure cover for the cables inside.

- Moulded seal is made from elastic material such as rubber or silicon. The main function of this part is to create a tight sealing layer, preventing the penetration of moisture and dust. Depending on the level of protection required, the part can be made from materials that demonstrate enhanced characteristics in extreme temperatures and environments.

- Clamping seal insert plays the role of securing cables, alleviating the strain and preventing cables from being pulled or twisted.

- Entry thread: is the point where cables are inserted into the cable glands. The choice of thread size must be compatible with the diameter and types of cables used.

In some cable gland configurations, there might be additional locknut (extremely useful for moving applications), O-ring (enhancing the tight sealing ability).

2. Selection criteria for cable glands

In order to select appropriate cable glands, users should take into account the following criteria:

2.1 Determining the size of cable glands

The choice of cable gland sizes hinges on the overall diameter, armor diameter, and the cable’s thickness. With many options available, users may find it difficult to select cable gland size that corresponds to the cables being used.

The first tip is to always aim to use cable glands from the same manufacturer for the entire system, as this provides maximum efficiency and performance. Manufacturers often provide information stating any specifications or conversions needed to measure cable glands. This data will help you easily measure and determine the appropriate cable gland size.

When measuring cable glands, you must first determine the type of cable being used . Determine whether the cable is armored or not. The difference between cable types is important because each type requires a different cable gland size. Unarmored cables are simpler to measure, as it is the diameter of the cable that matters.

Meanwhile, armored cables require some additional measurements and considerations. Some of these considerations include:

- Diameter of the inner bedding.

- Diameter of armor layer.

- Size and type of armor.

- Type and material of cable sheath.

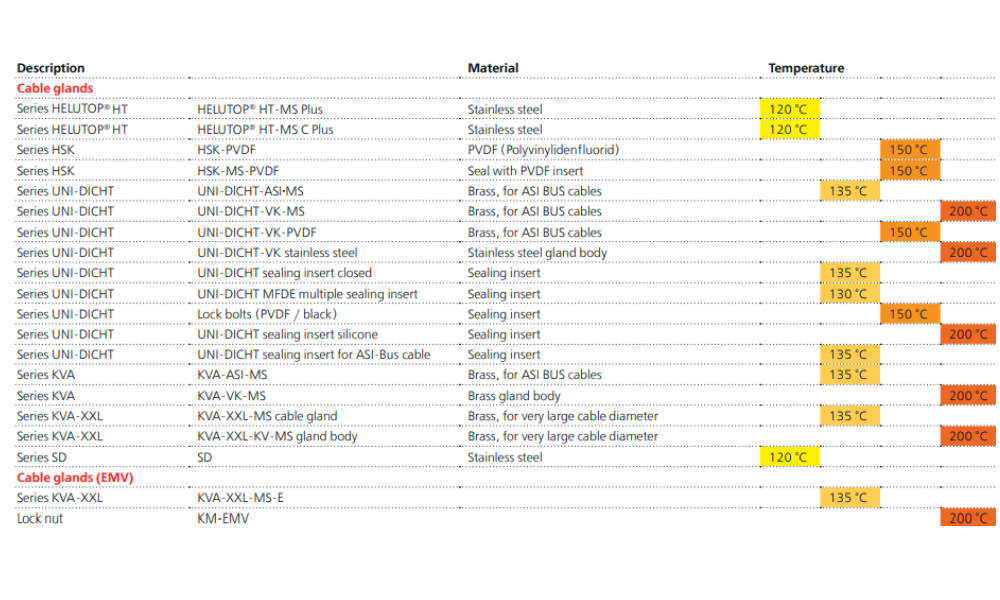

Operating temperature of some cable glands from HELUKABEL

2.2 Environmental conditions

A crucial factor to consider when choosing cable glands is the environment in which they are occupied. If the cable glands are exposed to harsh weather conditions or other hazards, you will need a seal that can withstand these conditions. Additionally, if the cable glands are used in a hazardous area, you need ones that are designed to meet the relevant safety standards.

Besides, you need to consider the expected operating temperature and pressure conditions in your application. Different types of cable glands are designed to withstand different temperature ranges and pressure levels.

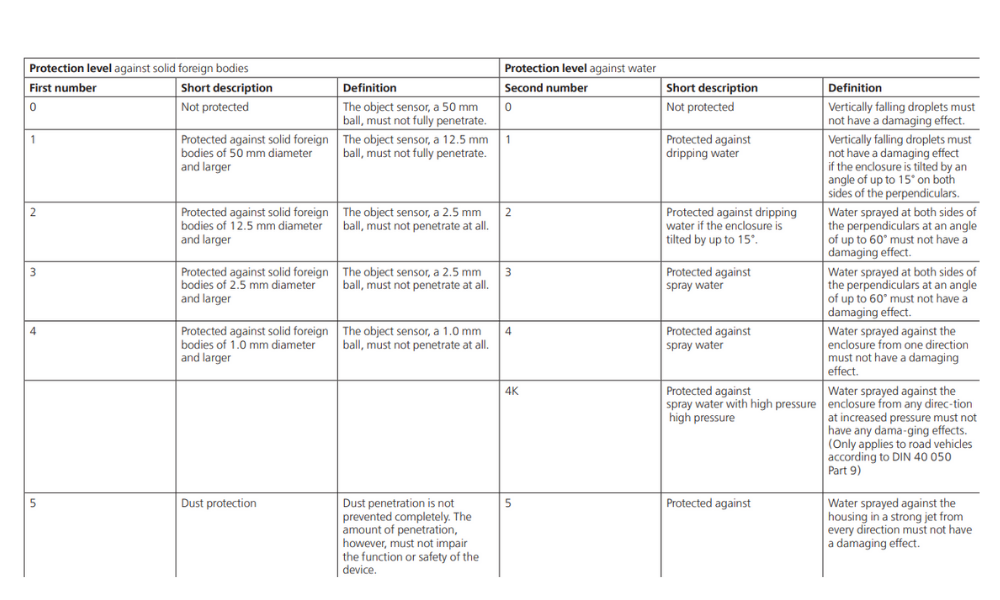

In addition, we should also pay attention to IP – Protection Classification. The IEC 60529 “Protection classifications using enclosure” (IP-Code)“ provides a system for classifying the protection ratings of electrical operating materials by enclosure. This standard defines terms for the protection classifications by enclosure concerning:

- Protection of persons against access to dangerous parts inside the enclosure

- Protection of operating material inside the enclosure against ingress by solid foreign substances

- Protection of operating material inside the enclosure against damage by the ingress of water

2.3 Cable glands materials

The choice of material used to make cable glands affects compatibility for each specific application:

- Copper cable glands have good thermal conductivity, suitable for elevated temperature and high-pressure environments. In addition, copper cable glands have good hardness and elasticity, so they are less likely to break compared to stainless steel.

- Stainless steel cable glands are commonly used in petrochemical, pharmaceutical, electronics and marine engineering applications. Outstanding corrosion resistance makes them ideal for use in wet environments where corrosion and rust are likely to occur. Furthermore, this type of cable gland has high longevity and durability, ensuring sustainable performance over extended periods of use.

- Nylon cable glands are suitable for many environments, including power lines, instrumentation, lighting equipment... Their main advantages include resistance to long-term water exposure, corrosion resistance, non-toxic and adaptable to temperatures from -40°C to 135°C.

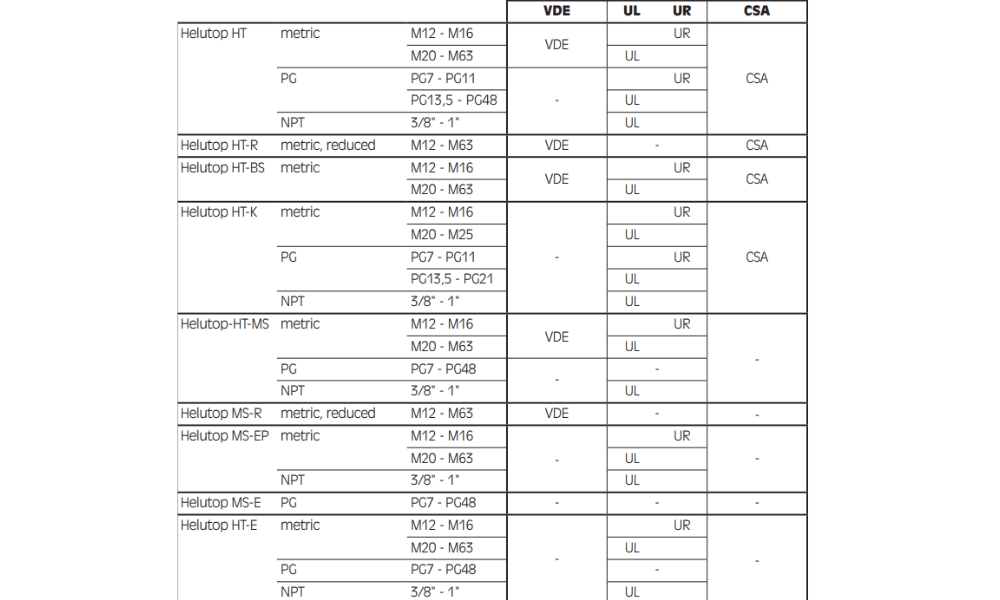

2.4 Selecting cable gland thread types

The three most common types of cable glands thread include:

- NPT (National Pipe Thread) has a 1/16 taper, meaning they taper towards the end. This taper allows the flanks of the thread to be effectively sealed together when twisted. NPT thread creates a reliable seal, making it suitable for applications where moisture or dust ingress needs to be minimized.

- Metric Thread: adheres to ISO metric system and ubiquitous in most IEC countries. Unlike NPT, metric thread does not have a taper. Metric thread is abbreviated “M”, followed by the diameter in millimeters (e.g., M12) and the pitch (e.g., M12 x 1.5).

- PG (Panzer-Gewinde) thread originates from Germany and is commonly used in electrical installations in Europe. PG thread has a smaller depth but larger flank angle than NPT thread and metric thread. PG thread is ideal for cable glands in harsh environments, providing a strong seal.

3. Cable gland installation process

The installation process for cable glands may vary depending on the specific type and design. However, the following steps outline the basic process of installing cable glands:

- Step 1: Choose the appropriate cable glands: Consider the cable type, diameter, and the environment in which they will be installed.

- Step 2: Prepare the cable: Strip the outer layer of the cable to expose the conductor. Follow the manufacturer's instructions regarding the required length of the stripped section.

- Step 3: Install the cable: Thread the cable through the cable glands, making sure the cable passes through the sealing mechanism.

- Step 4: Secure the cable glands: Depending on the type of cable glands, either screw into the device or enclosure or use a compression mechanism to secure the cable in place.

- Step 5: Tighten the cable glands: Use appropriate tools to safely tighten the cable glands. Be careful not to overtighten as this may damage the cable or gland.

- Step 6: Check the installation: After installing the cable glands, perform a visual check to ensure that the cable is properly positioned, and the gland is properly secured. Conduct any necessary checks to verify connection integrity.

4. A few notes for cable gland installations

Proper cable gland installations require technical knowledge and skills of users as follows:

4.1 Installation tools

While installing cable glands, you need to choose some supporting tools and accessories to ensure a safe installation process without damaging any materials or equipment. Each type of cable gland will require the support of different tools, such as:

- HELUTOP® HT plastic cable gland: Adapter PA, O ring, HELUTOP® HT-MFDE sealing insert.

- HELUTOP® HT-E brass cable gland is compatible with O-ring FPM, VS-O stainless steel.

- HELUTOP® MS-EP and HELUTOP® MS-EP4 EMC cable glands match the following accessories: electric scissors, hexagon adapter.

4.2 Installation standards

Similar to most electrical equipment intended for industrial use, cable glands are subject to regulations to ensure that every product meets the highest possible standards of safety, performance and long-term reliability. Some popular standards include:

- IEC & EN 62444: for cable glands used in electrical installations.

- IEC 60079: explosive atmospheres (Parts 0, 1, 7, 11, 14, 15, 17, 31...).

- IEC 61892: installations for mobile and fixed offshore installations.

- IEC 60092: for electrical installations on ships.

4.3 Safety issues while installing

You need to ensure safety during installation in many ways, such as:

- Make sure you do not damage the threads during installation.

- Different components of cable glands are compatible with each other only if they come from the same manufacturer. Furthermore, installing components from the same manufacturer will ensure the safety of the installation process.

- The sealing rings come with cable glands from the time of production. Under no circumstances should the sealing ring be removed from the cable glands. Additionally, do not expose the sealing rings to dirt, chemicals, and other foreign objects.

4.4 Cable gland assembly: Checking the performance

After installation, you must check the performance to ensure the cable glands are well-functioned:

- Sealing performance: Test the seal for fit, functional performance and reliability. Factors that can affect cable gland performance include material selection, sealing design, and a valid and effective testing program. Various tests include tensile resistance, thermal endurance, ingress protection and cable anchorage.

- Armor clamping: Loose clamps can also lead to improper installation of cable glands. Using the correct armor and clamp will ensure that you create the proper termination to secure the armor wire during the tightening process.

- Earth continuity: If you do not clamp the armor wire properly, it will adversely affect the potential balance. With the right armor clamping method, you can create a low-impedance termination without self-loosening, suitable for grounding.

If you still have any concerns or questions, don't hesitate to reach out to HELUKABEL Vietnam's engineering team promptly for detailed assistance.

HELUKABEL® Vietnam

905, Nguyen Kiem Street, Ward 3, Go Vap District, Ho Chi Minh City 700000, Vietnam

Tel. +84 28 77755578 | info@helukabel.com.vn | www.helukabel.com.vn