What are cobots? Using cobots at the production facility of HELUKABEL

Cobots are used at our Windsbach production facility, reducing manual labor and contributing to improved efficiency.

1. A glance at cobots

1.1 What are cobots?

A cobot (collaborative robot), often referred to as a "collaborative robot," is a form of robotic automation designed to work safely alongside humans in a shared workspace. In most applications, cobots are responsible for performing repetitive and simple tasks, while human workers focus on more complex jobs that require critical thinking. The precision, continuous operation, and repeatability of cobots are designed to complement human intelligence and problem-solving abilities.

1.2 What differs cobots from traditional robots?

The design of cobots differs significantly from traditional industrial robots. With rounded edges, force limitations, and lightweight construction, cobots are primarily designed with safety. Most cobots are equipped with a range of sensors to avoid collisions with humans, along with safety protocols that automatically stop operation in the event of any unintended contact. Their ability to work collaboratively with humans greatly expands the potential applications of robotic automation. An increasing number of industries are recognizing the benefits this technology brings.

2. Cobots at the production facility of HELUKABEL

The HELUKABEL production facility in the Franconian city of Windsbach was already one of the most modern of its kind. Now, the location is investing further in the automation of their manufacturing processes. As of recent, a cobot (a collaborative robot) has been supporting employees in mounting parts onto the specialized, automated machines.

2.1 Cobots replace manual works

The screening material, that many cables and wires produced by HELUKABEL are braided with, is delivered on large drums. To further process the material, it must then be rewound onto smaller spools, which are mounted onto the automated braiding machines. The empty spools must be placed into the winding machine and then removed once fully wound. It's monotonous work, which until now has been done by hand. Much to the pleasure of the employees, the robot is now performing these tasks fully automatically. They are now able to focus on more important tasks.

2.2 Benefits of using cobots at the production facility of HELUKABEL

"Manually handling the spools was not only monotonous but made keeping up with increasing production speeds exceptionally difficult," explains Project Lead Peter Bluhm. "With the new cobot, our teams operating the braiding machines can work not just more ergonomically, but also more efficiently." A magazine with 200 spools serves as a buffer to reduce downtimes and thereby increase productivity. The loaded spools are stacked onto a pallet by the robot. From here, the employees can comfortably mount the spools onto the different automatic braiding machines. A safety system allows the use of the cobot without the need for further protective equipment. The system is certified by the TÜV, a group of independent testing organizations.

"By automating this process step, we can save a lot of time and effort," says Bluhm. "This is right in line with our lean management concept." Further investments in automation and digitalization in Windsbach have already been planned. The HELUKABEL plant will continue in the future to be considered one of the most modern of its kind.

3. HELUKABEL’s cables and wires for cobots and robots

3.1 Operating environment of cobots and robots

Cobots and robots are an essential part of highly dynamic manufacturing industries around the world, and it is difficult to imagine these industries without them. Robots and cobots can be found operating and interacting in close proximity with humans on production lines, but they also perform tasks independently. Modern industrial robots move in three-dimensional space and are able to carry out a great variety of tasks. In doing so, the robot, or rather the robot arm, repeats a sequence of movements millions of times. It nevertheless completes repetitive work processes with continuous precision while maintaining consistent quality – without daily variations or signs of fatigue.

3.2 Requirements for cables used in cobot and robot applications

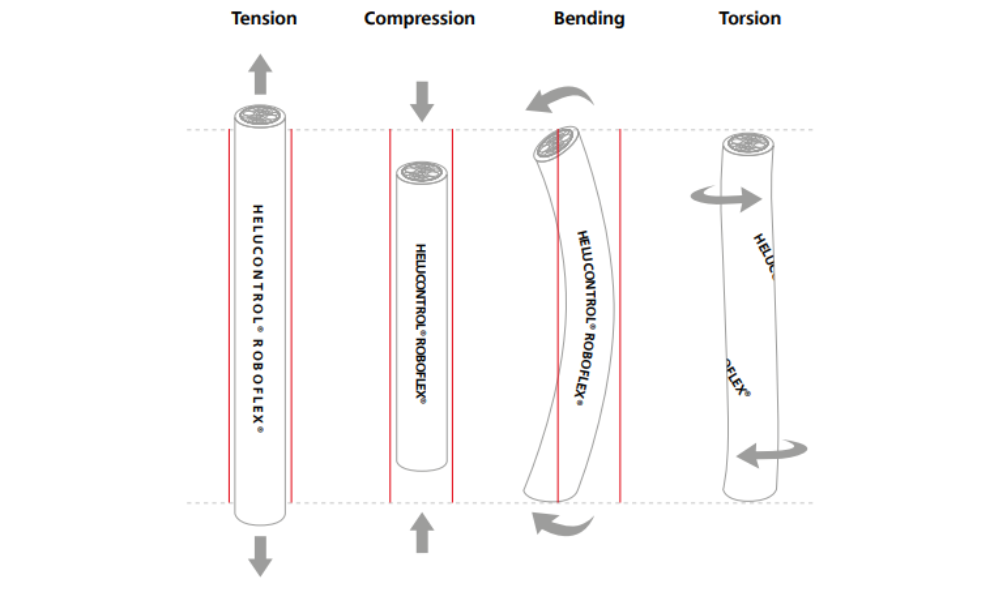

In order to be able to do this, the cables in the cobots and robots must meet the highest standards:

- Rapid acceleration and deceleration, tensile loads as well as combined bending and torsional movements are just a few of the operating conditions taken into account during cable design.

- At the same time – and depending on the application – space-saving solutions are needed to feed the cables into or along the robot arm whilst maintaining the greatest possible freedom of movement.

- Mechanical stress as well as chemical and thermal factors often play a role here too.

3.3 HELUKABEL’s cables for cobot and robot applications

With our Roboflex® brand of cables, we have the right solution for a wide variety of applications. Resistance to oil, abrasion, notch and welding beads or extreme bending radii are just some of the requirements fulfilled by our cables. Some of these cables are: HELUCONTROL® ROBOFLEX®-D, HELUDATA® ROBOFLEX®-D-PAAR, HELUPOWER® ROBOFLEX®, HELUKABEL® ROBOFLEX®-recycle…

HELUKABEL’s assortment of cables for robotic applications includes control and motor cables of many different dimensions, hybrid cables and cables for the sensor and data, network and bus technology sectors:

TOPSERV® Hybrid PUR, TOPGEBER 512 PUR, MULTISPEED® 500-PUR UL/CSA, PROFInet Type R, H07V-K / 07V-K, FIVENORM PROFInet Type A or B…

>>See more: TOPSERV PUR cable series for drag chain applications

>>See more: VFD cables for drive technology

If you still have any concerns or questions, don't hesitate to reach out to HELUKABEL Vietnam's engineering team promptly for detailed assistance.

HELUKABEL® Vietnam

| Address | 905, Nguyen Kiem Street, Ward 3, Go Vap District, Ho Chi Minh City 700000, Vietnam |

| info@helukabel.com.vn | |

| Hotline | +84 28 77755578 |

| Website | www.helukabel.com.vn |

| Discover our products and place orders | Tiki | Product finder |

| Follow us on | Facebook | LinkedIn | Instagram | Youtube | Zalo | WhatsApp | Tiktok | Spotify |