Marathon drag chain system: Solutions for long travel distances

In addition to plastic and steel drag chains, the Marathon system is a special solution from Hệ thống xích dẫn cáp Marathon của HELU Connectivity Solutions Haan GmbH. Let’s explore this innovative solution in the following article!

1. A glance at drag chains with rollers

1.1 Drag chains used in heavy-duty applications

In heavy-duty industries such as mining, machine building, steel production, drag chains used must withstand heavy loads and operate efficiently under high pressure. These drag chains are designed to support the weight of cables and cable accessories without causing any damage. In addition, drag chains used in these industries often need to travel over long distances or navigate curves, requiring smooth and stable movement. As the distance increases, so does the risk of cable damage and system inefficiencies, which can lead to costly maintenance and downtime. This is where drag chains with rollers become essential.

>>See more: Why are drag chains used in various industries?

1.2 What are drag chains with rollers?

Drag chains with rollers offer a safe and reliable solution when sliding systems are impractical due to long travel distances or excessive friction. In these systems, the upper section of the drag chain runs on rollers rather than sliding over the lower section. These rollers are mounted on ball bearings along both sides of the chain, enabling it to travel over extended distances while significantly reducing the power needed for operation.

In sliding systems, direct contact between the upper and lower sections of the drag chain increases friction over time, leading to wear and tear, system inefficiency, or even failure—particularly in applications with heavy loads or long travel distances.

By incorporating rollers, friction is greatly minimized. This allows the drag chain to move more smoothly, extending the system’s lifespan, reducing maintenance costs, and ensuring stable operation. This is especially crucial in industries where long travel distances are common, such as cranes, steel mills, and port machinery.

>>See more: Drag chains from EKD Systems

2. A glance at drag chain systems with roller – Marathon systems

Marathon Systems from HELU Connectivity Solutions Haan GmbH.

2.1 About HELU Connectivity Solutions Haan GmbH

HELU Connectivity Solutions Haan GmbH. is a German-based company belonging to the HELUKABEL Group. Founded in 1970 by Ernst Klein, HELU Connectivity Solutions Haan GmbH. is a developer and manufacturer of steel, stainless steel, and plastic drag chains. At HELU Connectivity Solutions Haan GmbH., we focus on providing customized system solutions tailored to customers’ needs, mainly for small and medium-sized orders. Currently, the company owns multiple machining centers, its own die, and mold-making department, and a fully automated plastic injection molding department.

2.2 Marathon Systems from HELU Connectivity Solutions Haan GmbH.

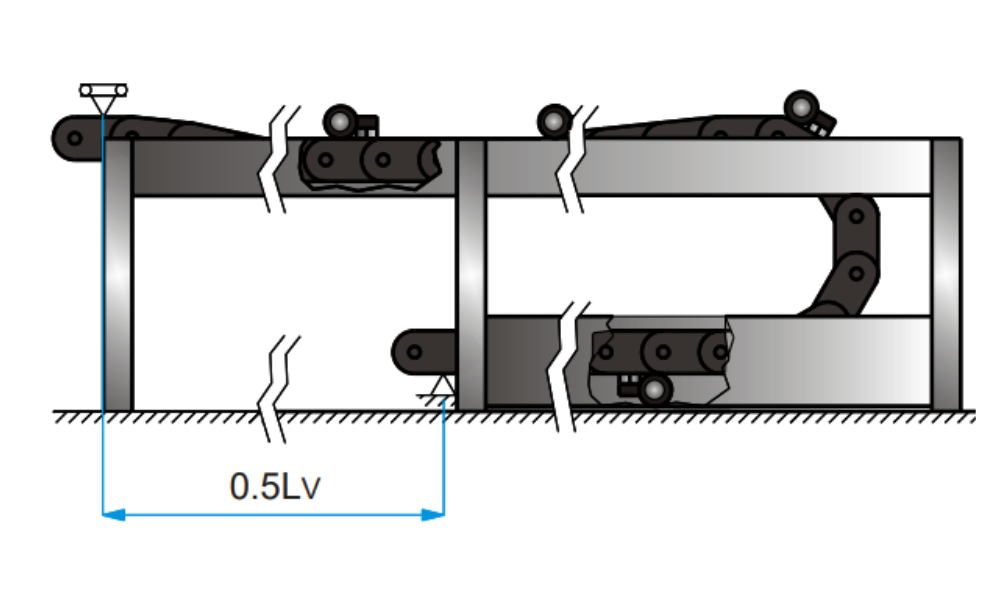

The Marathon systems are patented solutions from HELU Connectivity Solutions Haan GmbH. for applications with unlimited travel distances, high speeds and high accelerations. The upper part of the drag chains runs over support rollers along the entire travel on continuous flat rails, and the rollers rotate at a radius to guide the drag chain on the lower rail. When moving in reverse, the rollers rotate out and guide the drag chains without wear during the entire travel. The Marathon systems are compatible with both steel and plastic drag chains, making it a versatile solution for various applications.

2.3 How the Marathon systems are operated?

The Marathon systems operate as follows:

- The upper part of the drag chains is mounted on rollers, which rest on a flat surface known as the guide rail. This design eliminates sliding friction between the upper and lower parts of the drag chain during movement.

- In front of the chain bend radius, the roller sets are lifted off the guide rails. As the chain enters the bend radius, the rollers rotate and engage the trough in a polygonal pattern, guiding the drag chain onto the lower guide rail.

- In the reverse direction, the rollers behind the bend radius rotate and grip the guide bar, ensuring the drag chain stays on its correct path without slipping.

3. Benefits of using Marathon drag chain systems with rollers

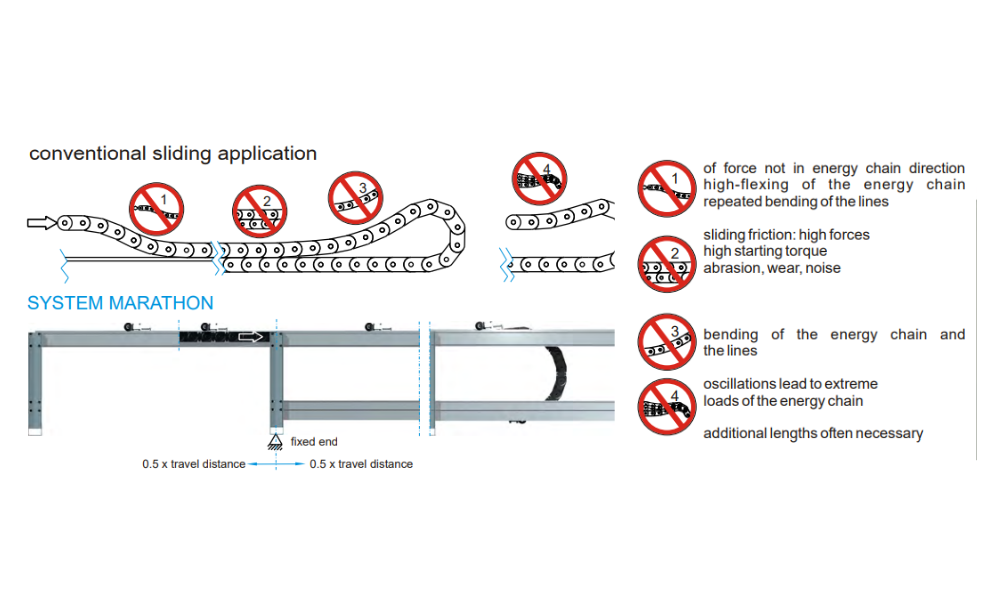

Marathon drag chain systems and conventional sliding drag chains

3.1 The reduction of sliding friction

One outstanding advantage of the Marathon systems is that, due to the roller guidance of the drag chain, it achieves a reduction of friction-related travel forces of up to 90%, resulting in energy savings and efficiency. This improves operating efficiency in applications requiring long-distance travel.

3.2 Reduced starting moments

Sliding friction between the upper and lower parts of the drag chains can generate significant resistance, leading to high starting moments and increased energy consumption. However, by eliminating sliding friction and incorporating rollers in the Marathon systems, starting moments are significantly reduced. This not only allows the system to run smoothly but also reduces mechanical stress, prolongs the lifespan of the drag chain, and conserves energy. In applications requiring long-distance travel, such as seaports, steel mills, or large production lines, lowering starting moments improves efficiency and minimizes maintenance costs.

3.3 The absence of alternating flexure, minimized wear

In the Marathon systems, force is applied parallel to the longitudinal direction of the drag chain, enhancing the system's stability and efficiency. Additionally, the absence of alternating bending between the cables and the drag chains minimizes the effects of pressure and wear on both components.

3.4 Increased lifespan

These aforementioned features help the Marathon drag chain systems extend its service life and ensure high reliability during operation. Additionally, if the rollers wear out, they can be easily replaced during maintenance, eliminating the need to replace the entire drag chain system, which would be costly and time-consuming. The systems are designed with grooves that allow for easy visual inspection and access to the rollers, saving time during maintenance and repairs.

4. Comparing Marathon drag chain systems and conventional sliding drag chains

4.1 Differences between Marathon systems and conventional sliding drag chains

| Conventional sliding drag chain | Marathon drag chain systems | |

| Friction | Using sliding drag chains, creating high friction, resulting in high force requirements and large starting moments | Sliding friction is eliminated due to the use of guide rollers |

| Abrasion resistance | The sliding contact between the upper and the lower parts of the drag chain causes rapid wear, reducing the service life | Reduced wear resistance |

| Bending | Subjected to repeated bending and high tension, which can easily damage the cables over time | The force is applied parallel to the longitudinal direction of the drag chain, avoiding alternating bending of the cable |

| Noise and vibration | The sliding mechanism creates noise and vibration when the drag chain operates. | Smooth operation, minimizing noise and vibration |

The use of conventional sliding drag chains often results in noise, wear, energy loss, and frequent maintenance due to repeated stress on cables and other components of the drag chain systems. In contrast, Marathon drag chain systems, which utilize guiding rollers instead of sliding mechanism, reducing up to 90% friction and saving energy significantly. These advantages enable Marathon drag chain systems to optimize performance whilst providing durability and stability in industrial applications that require high speeds and heavy loads.

Projects used Marathon systems from HELU Connectivity Solutions Haan GmbH.

4.2 Applications of Marathon drag chain systems

This highly efficient solution is well-suited for numerous applications, including the replacement of sliding chains, cable reel systems, festoon systems, and busbar systems. It is extensively used in ship-to-shore operations, particularly in container handling for RTG and STS cranes, as well as in bulk and coal material handling. Furthermore, the Marathon System offers versatility for use across a wide range of industries.

5. HELUKABEL’s comprehensive drag chain solutions for heavy-duty applications

The Marathon drag chain system completes HELUKABEL’s solutions for heavy-duty industries, offering customers a comprehensive solution:

5.1 Marathon drag chain systems for harsh environmental conditions

Modern industrial systems, such as cranes, hoists, and festoons, increasingly demand faster operating cycles and higher speeds. The Marathon systems are fully capable of meeting these requirements, offering high-speed operation, rapid acceleration, and exceptional durability.

5.2 HELUKABEL’s drag chain compatible cables

HELUKABEL’s product portfolio encompasses various cables that are specifically designed for drag chains , ensuring high performance even in the harshest conditions. With their resistance to abrasion, heat, and continuous bending, our cables and wires meet the stringent demands of heavy-duty industries, enhancing system reliability. At our Windsbach manufacturing facility, these products undergo rigorous testing to ensure that our customers receive the highest quality.

>>See more: Put to the Ultimate Test – Part 3: Drag Chain Tests at Windsbach

5.3 Customized solutions tailored to customer’s needs

Understanding that each business has unique technical requirements, HELUKABEL offers flexible, customized solutions tailored to the specific needs of each customer. From cable design and construction materials to complex drag chain systems, we are committed to delivering the most optimal solutions. Our flexibility in meeting customized demands makes HELUKABEL a reliable partner for both large and small projects, contributing to improved operational efficiency and ensuring absolute safety.

If you still have any concerns or questions about Marathon systems, don't hesitate to reach out to HELUKABEL Vietnam's engineering team promptly for detailed assistance.

HELUKABEL® Vietnam

| Address | 905, Nguyen Kiem Street, Ward 3, Go Vap District, Ho Chi Minh City 700000, Vietnam |

| info@helukabel.com.vn | |

| Hotline | +84 28 77755578 |

| Website | www.helukabel.com.vn |

| Discover our products and place orders | Tiki | Product finder |

| Follow us on | Facebook | LinkedIn | Instagram | Youtube | Zalo | WhatsApp | Tiktok | Spotify |