What are drag chain cables? A glance at drag chain cable TOPSERV® PUR

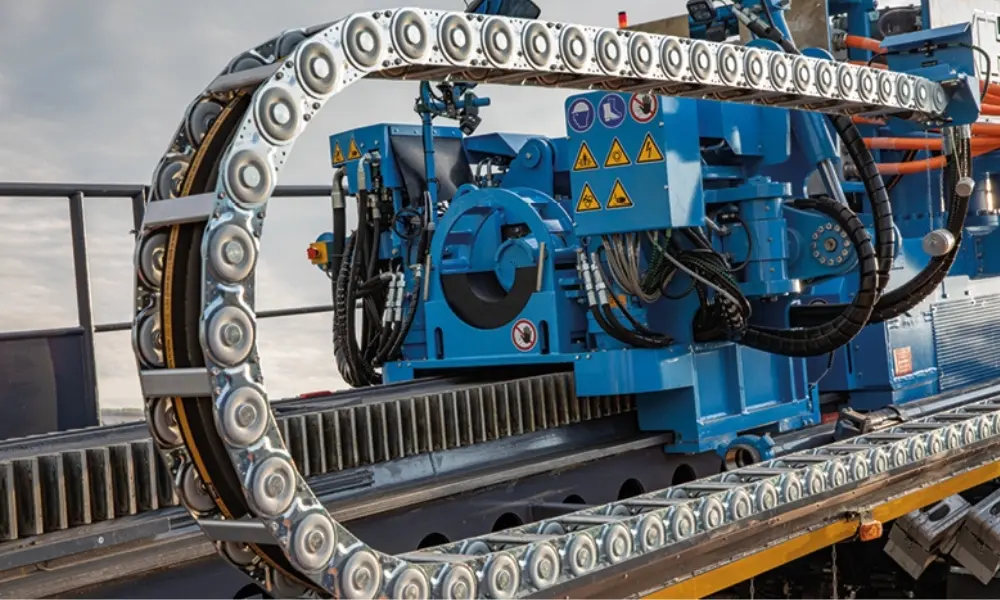

Drag chains, which are characterized by continuous movements, require compatible drag chain cables. Let’s find out more about this topic and drag chain cable TOPSERV® PUR.

1. What are drag chain cables?

In modern industrial and technical applications, drag chains play an extremely important role and are widely used. Specially manufactured cables used in drag chains are highly flexible and sturdy, capable of withstanding harsh environments and continuous movement. These cables effectively organize and secure power, data, and pneumatic lines, ensuring smooth system operation and reducing damage. They are used in many industries , including automation, robotics, and instrumentation. These cables are essential for increasing equipment lifespan and ensuring continuous operation in challenging environments through reliable performance.

>>See more: A glance at drag chains and whey are they used?

2. Characteristics of drag chain cables

Drag chains protect cables within automatic machinery and equipment by shielding them from strain caused by constant movement. However, not all cables perform well in this harsh environment. Drag chain cables are specifically made to withstand repeated bending. Therefore, these cables possess the following characteristics:

- Outstanding flexibility: Standard cables are made for fixed installations, thus being incapable of withstanding continuous movement of drag chain. Therefore, drag chain cables are made from highly flexible materials, allowing them to bend many times without breaking. Additionally, the point where the cable connects to the plug or terminal is especially susceptible to strain when moved. These cables incorporate powerful strain relief mechanisms at the terminations, preventing excessive pulling forces from damaging connection points and ensuring the wire stays in place.

- Abrasion resistance: The operating environment of the drag chains can be harsh on the outer sheath of cables. Constant rubbing against drag chains and other cables can quickly wear out standard cables. Therefore, the cables used must have a durable, abrasion-resistant protective sheath, usually made of polyurethane (PUR). This special material acts like armor, protecting the delicate wires inside from scratches or cuts.

- Bio-oil and chemical resistance: In industrial environments, machinery and equipment are likely to encounter coolants, oils, and other chemicals. The outer sheath of drag chain cables is specifically designed to resist these agents, protecting the functionality and lifespan of the cables.

3. Classification of drag chain cables

Standard drag chain cables: these cables are specifically made for use in drag chains. Their flexible, rugged design resists bending and twisting during the constant movement of drag chains, allowing reliable data or power transmission in industrial automation systems.

Highly flexible drag chain cables: Designed to withstand intense bending cycles, these highly flexible cables offer greater adaptability and resistance to stretching. They are the perfect choice for highly dynamic automation systems with continuous movement and frequent changes in cable direction.

Oil-resistant drag chain cables: Oil-resistant drag chain cables maintain performance and durability in environments exposed to oil and lubricants. They protect electrical equipment and ensure uninterrupted signal transmission.

Anti-interference drag chain cables: Shielded to prevent EMI and RFI, these cables are ideal for use in environments with magnetic interference. They ensure signal integrity and minimize signal loss.

>>See more: MULTIFLEX 512®-PUR UL/CSA drag chain cables for physical impcat environment

4. A glance at drag chain cable TOPSERV® PUR

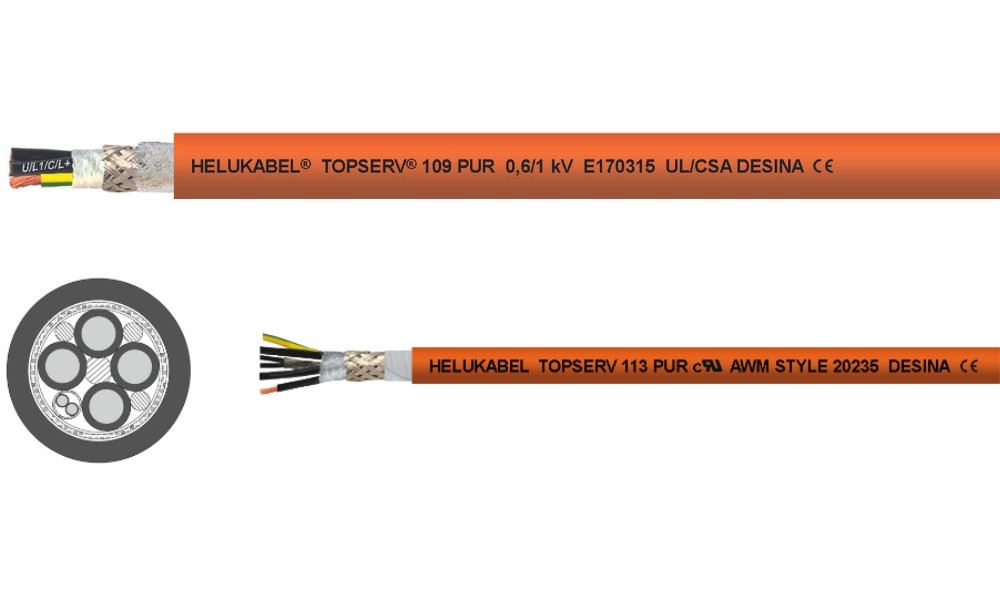

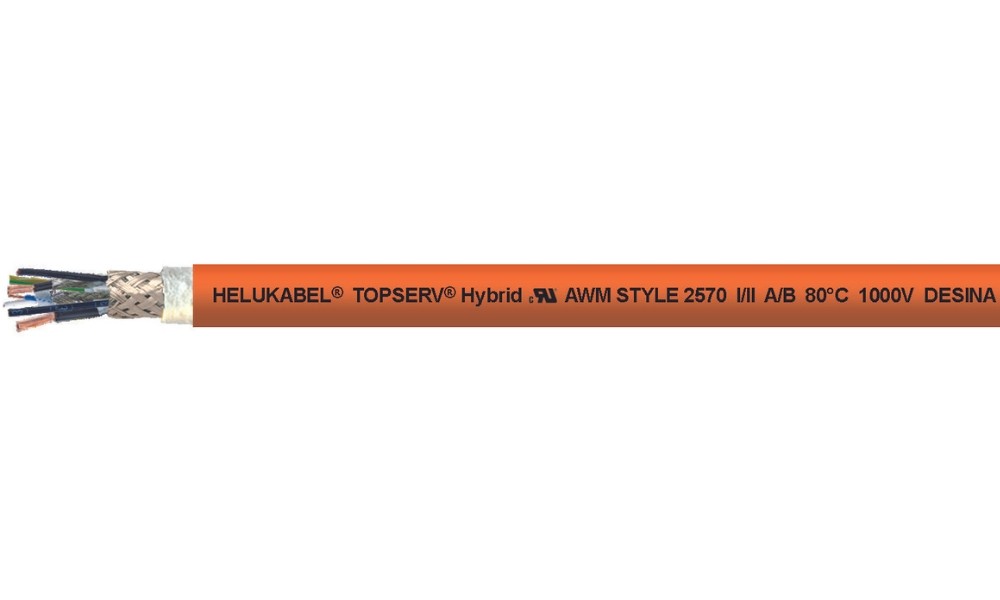

In this article, 2 types of PUR drag chain cables are presented: TOPSERV® PUR and TOPSERV® Hybrid.

4.1 Characteristics of PUR materials

PUR drag chain cables are halogen-free, fire-resistant, with enhanced mechanical and chemical resistance, which render them resilient and suitable in harsh environments. In addition to being abrasion-resistant, PUR also inhibits the growth of bacteria and germs, making this cover material particularly suitable for use in the food and beverage industry, clean rooms, and other hygiene-compliant production lines.

Using PUR as the outer sheath material also maintains the cables’ flexibility. As a result, PUR cables are compatible with applications requiring frequent or continuous bending, such as drag chains, conveyors, flexible drum winding cables for festoons and equipment moving machinery, control cables for robots, and machine tools.

4.2 Technical data of TOPSERV® PUR and TOPSERV® Hybrid drag chain cable

TOPSERV® PUR and TOPSERV® Hybrid are PUR drag chain cables, operating well in environments with temperature from -30°C to +80°C when flexing and -40°C to +90°C for fixed installations. At the same time, the PUR outer sheath is flame-retardant and self-extinguishing, adhering to DIN VDE 0482-332-1-2 / DIN EN 60332-1-2 / IEC 60332-1-2 standards, which helps to prevent fire incidents.

There is a certain level of resemblances between these two drag chain cables:

- Nominal voltage according to VDE U0/U 600/1000 V, UL/CSA is 1000 V.

- Insulating resistance: min 20 MOhm x km.

- Coupling resistance: max 250 Ohm/km

- Minimum bending radius:

Flexing7,5x cableØ

Fixed installation 4x cable Ø

Data sheet of TOPSERV® PUR drag chain cable

Data sheet of TOPSERV® Hybrid drag chain cable

4.3 Structure of the cables

In terms of structure, TOPSERV® PUR and TOPSERV® Hybrid drag chain cables share the following similarities:

- Copper conductor, extra fine wire according to DIN VDE 0295 class 6 and IEC 60228 class 6.

- Insulation is made from halogen-free material – PP.

- GN-YE conductor.

- Overall screening from tinned copper braid, optimal coverage approx. 85%.

- The outer sheath is made from PUR material with orange colour.

Screening of the control cores in pairs wrapped with tinned copper braid. Power supply cores laid up with optimal lay length and stabilizing filler. Cores can be identified as follows:

| TOPSERV® PUR | TOPSERV® Hybrid | ||

| Power supply cores | Core 1: black with imprint U/L1/C/L+ Core 2: black with imprint V/L2 Core 3: black with imprint W/L3/D/L | ||

| Control cores | TOPSERV® 109 PUR | No control cores | Core 1: black with number no. 5+6 Core 2: white and blue |

| TOPSERV® 113 PUR | With one control cores According to Siemens Core 1: black with imprint BR1 Core 2: black with imprint BR2 According to Lenze Core 1: brown with imprint BR1 Core 2: white with imprint BR2 | ||

| TOPSERV®121 PUR | With 2 control cores Pair 1: black with number no. 5+6 Pair 2: black with number no. 7+8 | ||

4.4 Properties of these two drag chain cables

TOPSERV® PUR and TOPSERV® Hybrid are highly compatible with drag chain due to the following characteristics:

- PUR outer sheath: low adhesion, extremely abrasion resistant, halogen-free, resistant to UV-, oil-, hydrolysis and microbial attack.

- Optimum compliance with requirements for EMC by approximately 85% coverage from braided screen.

- These cables are produced to high quality specifications and conform to the DESINA® standards.

- The materials used during manufacturing are cadmium-free, contain no silicone and are free from substances harmful to the wetting properties of lacquers.

TOPSERV® Hybrid drag chain cables possess low capacitance properties, which help reduce signal loss and latency due to electrical build-up between conductors. Additionally, the servo motor cable and feedback cable are combined into a single cable, reducing installation time and saving space in the drag chain. The TOPSERV® PUR cable line is also resistant to cleaning and disinfecting agents according to ECOLAB® standards.

>>See more: Anti-inteference signal cable for drag chains

4.5 Applications of TOPSERV® PUR and TOPSERV® Hybrid

TOPSERV® Hybrid are not only compatible with drag chain applications. Besides, the supply conductors for these cables are ideally combined with the control conductors for the brake function and the transmission of the Sick Hiperface DSL protocols. Applications include machine, plant and robot construction.

TOPSERV® PUR drag chain cables find wide applications:

- The combination of supply cores with the control cores for the braking function and thermal protection in these cables is ideal.

- Precision servomotors, as used today in many areas of highly automated manufacturing processes, call for high-quality, reliable and long-lasting, anti-interference cables.

- Production is based on the specifications of established manufacturers of servo-drives and controls, as well as on various VDE, UL and CSA standards.

- Applications include machine, plant and robot construction, automation, drive, control and production engineering.

- Attractive for export-oriented mechanical and system engineering.

If you still have any concerns or questions, don't hesitate to reach out to HELUKABEL Vietnam's engineering team promptly for detailed assistance.

HELUKABEL® Vietnam

905, Nguyen Kiem Street, Ward 3, Go Vap District, Ho Chi Minh City 700000, Vietnam

Tel. +84 28 77755578 | info@helukabel.com.vn | www.helukabel.com.vn