Frequently asked questions about brass cable glands

We have compiled some frequently asked questions about brass cable glands to help users easily choose the right gland for their application. Let's explore through the following article!

1. How many types of brass cable glands are there?

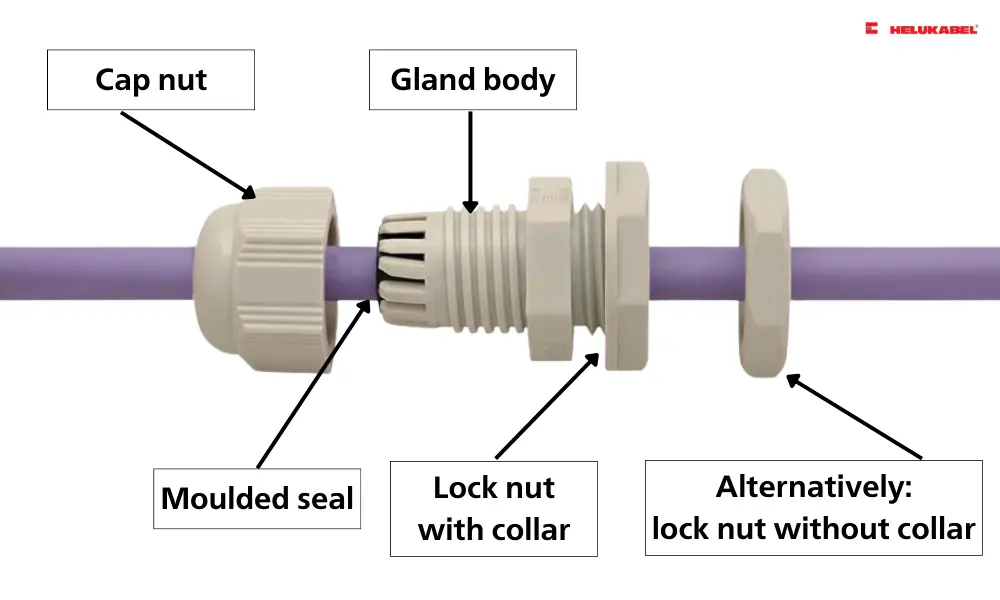

Brass cable glands come in various types and sizes to meet different needs. Understanding these types helps you select the right one for your application. Common types include:

- Single compression brass cable glands: Designed for basic strain relief with a single compression mechanism, suitable for less demanding environments.

- Double compression brass cable glands: With dual compression points, these cable glands provide enhanced protection against dust and moisture, making them ideal for harsher conditions.

- EMC brass cable glands: These protect both cables and machinery from electromagnetic interference (EMI), which can affect the functionality of electrical equipment. Acting as a barrier against EMI at the connection point, these cable glands are commonly used in telecommunications and environments where EMI could disrupt machinery operations.

- Explosion-proof brass cable glands: These are engineered to prevent sparking in environments with explosion risks.

- Weatherproof brass cable glands: Equipped with sealing gaskets, these brass cable glands protect cables from rain, dust, and extreme temperatures.

2. Can brass cable glands be used for all types of electric cables?

Brass cable glands are suitable for most types of cables and are widely used across various industries. However, they may not be ideal for certain specialized environments, such as the chemical manufacturing industry, where reactive substances could affect the durability of brass. Therefore, it’s essential to carefully assess the level of chemical exposure and environmental conditions before selecting brass cable glands. Additionally, choosing the correct specifications and sizes is crucial to ensure compatibility and effectiveness during cable installation.

3. Quality standards for brass cable glands

3.1 Which quality standards must brass cable glands meet?

Brass cable glands are used in various environments, requiring them to be certified with multiple quality standards. Some common standards for brass cable glands include:

- CE marking for European market: Ensures that products can circulate freely within the European Economic Area.

- ROHS certification: Restricts the use of hazardous materials in electrical and electronic products.

- ISO standards: Includes procedures, processes, and policies for planning and implementation in an organization’s core business activities.

- IP68 waterproof certification: Demonstrates that the cable gland meets IP68 standards for waterproofing, which is crucial for many applications.

- ATEX certification: Indicates that the brass cable gland has good explosion-proof capabilities, making it suitable for use in hazardous areas.

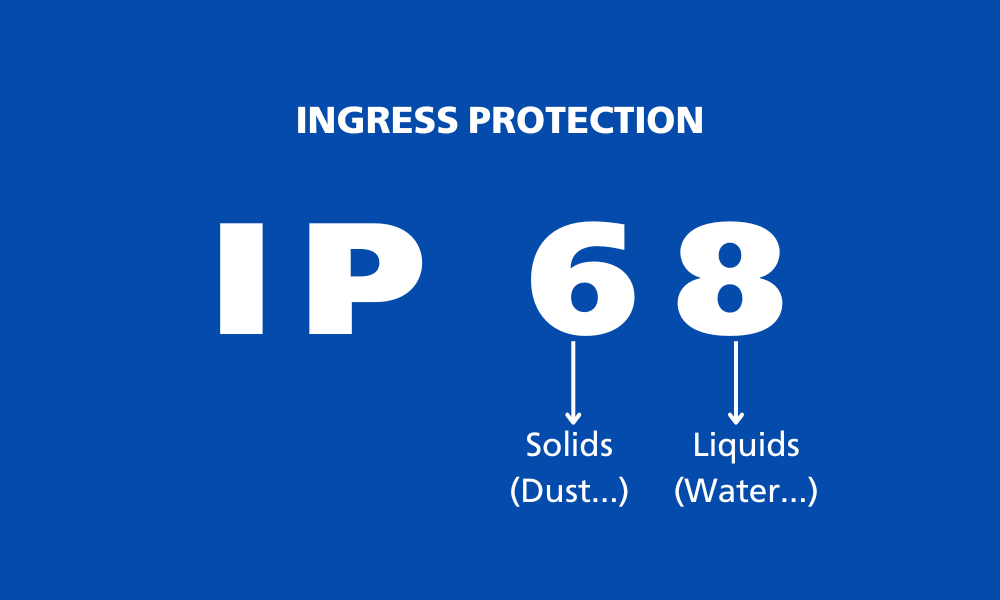

3.2 Is IP rating important when selecting brass cable glands?

IP (Ingress Protection) ratings are critical when selecting brass cable glands, as they determine the level of protection against dust and liquids. These ratings reflect the cable glands’ ability to safeguard the electrical equipment they connect to. The rating consists of two digits: the first indicating protection from solid objects, and the second indicating water resistance.

Common IP ratings include:

- IP65: Suitable for outdoor environments, dustproof, resistant to low-pressure water jets.

- IP66: More durable, resistant to strong water jets.

- IP67: Protects aginst temporary submersion, such as during floods.

- IP68: Suitable for long-term underwater use, where the brass cable glands are completely submerged.

Many of HELUKABEL's brass cable glands are IP 68 certified. This is the highest IP rating, ensuring durability and performance in harsh conditions. Some of HELUAKBEL's brass cable glands that meet IP68 standards include:

| IP 68 - 5 bar | IP 68 - 10 bar / IP 69K |

| HELUTOP® HT-MS HELUTOP® MS-EP HELUTOP® MS-EP4 VMK-SD | HSK-MS-E HSK-MS HSK-MS-E-D HSK-MS-L |

>>See more: Features of HELUTOP HT-MS brass cable glands

HELUKABEL's brass cable glands for explosive areas

3.3 How to select brass cable glands for hazardous areas?

For hazardous environments, selecting brass cable glands that meet strict safety standards, such as ATEX or IECEx certification, is recommended. In these cases, explosion-proof or flame-resistant brass cable glands should be prioritized. Users should consult cable gland suppliers who specialize in these types of connectors to ensure that the product is suitable for the intended use.

Understanding the different types of explosion-proof brass cable glands and their specific features is essential to making the right choice for your industry needs:

- Enhanced safety cable glands (Ex e): Prevent the risk of sparking and protect the circuit from external explosion. These cable glands are suitable for areas with intermittent gas and dust hazards.

- Explosion-proof cable glands (Ex d): These cable glands are capable of containing an explosion within the equipment, making them ideal for environments where explosive gases or dusts are present frequently or continuously. They are designed to withstand harsh conditions, ensuring that any ignition source is completely isolated from the hazardous environment, helping to keep the electrical system and surrounding area safe.

- Dust-proof cable glands (Ex t): are specifically designed for areas with high dust concentrations, helping to prevent dust from entering and protecting against the risk of ignition from combustible dust layers or plumes. These brass cable glands are important for industries that handle fine particles, which can pose a significant explosion risk.

- Extreme temperature cable glands: Some environments are not only potentially explosive, but also operate in extreme temperature conditions. Cable glands designed for these environments are capable of withstanding both extreme cold and hot temperatures, ensuring their integrity and function are not affected by temperature changes.

4. Comparing brass cable glands and other common types of cable glands

HELUKABEL's stainless steel cable glands

4.1 What are the differences between brass and stainless-steel cable glands?

Brass cable glands and stainless-steel cable glands are both made of metal. However, brass cable glands are made from a copper alloy, while stainless-steel cable glands are made from an alloy of iron combined with chromium and nickel.

In terms of corrosion resistance, brass cable glands are considered superior. However, stainless-steel cable glands have better resistance to petroleum products and many types of acids than brass. Some stainless-steel cable glands even outperform brass in harsh marine environments.

One of the biggest differences between brass cable glands and stainless-steel ones is that stainless-steel contains no lead at all. Stainless-steel is very hygienic and resistant to bacteria, microorganisms, and harsh detergents, helping to maintain normal operations in production lines. Therefore, stainless-steel cable glands are widely used in the F&B industries.

Plastic cable glands from HELUKABEL

4.2 What are the differences between brass and plastic cable glands?

Plastic cable glands are made from materials such as polyamide or nylon. Compared to brass cable glands, plastic cable glands are more cost-effective, lightweight, flexible, and easier to assemble. Additionally, the electrical insulation properties of plastic cable glands provide significant advantages in applications where electrical conductivity needs to be avoided. In contrast, brass cable glands exhibit superior mechanical strength and can withstand high temperatures, making them suitable for harsh operating environments.

HELUKABEL understands that each application requires a different type of cable gland to ensure the highest performance and safety. In addition to brass cable glands, HELUKABEL also offers plastic and stainless steel cable glands to meet diverse usage needs in various environmental conditions, from standard to harsh environments. With a wide product range, HELUKABEL is committed to providing comprehensive solutions that meet all of the customers' technical requirements.

If you still have any concerns or questions, don't hesitate to reach out to HELUKABEL Vietnam's engineering team promptly for detailed assistance.

HELUKABEL® Vietnam

| Address | 905, Nguyen Kiem Street, Ward 3, Go Vap District, Ho Chi Minh City 700000, Vietnam |

| info@helukabel.com.vn | |

| Hotline | +84 28 77755578 |

| Website | www.helukabel.com.vn |

| Discover our products and place orders | Tiki | Product finder |

| Follow us on | Facebook | LinkedIn | Instagram | Youtube | Zalo | WhatsApp | Tiktok | Spotify |