What are fiber optic connectors? Common types of fiber optic connectors

Fiber optic connectors are used to connect optical fibers, allowing the transmission of information in the form of light. Let’s explore the different types of fiber optic connectors as well as some key considerations when selecting a suitable connector in the following article!

Contents:

1. What are fiber optic connectors?

2. Components of fiber optic connectors

3. Common types of fiber optic connectors

LC, ST, SC, FC conectors

MPO/MTP connectors

4. Things to know while selecting fiber optic connectors

Polishing stypes: APC and UPC

Single-mode and Multimode cables

Simplex and Duplex connectors

Fiber optic patch cords

1. A glance at fiber optic connectors

1.1 Two methods for connecting fiber optic system components

In electrical systems, current or electrical power is used to transmit energy or communicate information between components and subsystems. Fiber optic systems primarily utilize optical energy to transmit information or data. Regardless of the data format or transmission rate in a fiber optic system, there are three functional stages carried out between various components and subsystems. A component may emit optical energy (such as LEDs and lasers), transmit optical energy (such as fiber optic cables and optical couplers), or receive optical energy (such as phototransistors and photodiodes).

To connect these fiber optic components and enable the transmission of optical energy within the system, two main methods are commonly used:

- Fiber optic connectors

- Splices

1.2 What are fiber optic connectors?

Fiber optic connectors are designed to mechanically align and join or terminate optical fibers, allowing two fiber optic cables to connect and disconnect quickly and safely. These connectors align the fiber cores mechanically, enabling light to pass through the cables without interruption.

Unlike splicing methods, where two fiber cores are permanently joined by fusion - heating the ends of the fiber cores to around 1600°C and then fusing them together - the use of fiber optic connectors allows technicians to inspect, maintain, and reconfigure networks with ease.

Most fiber optic connectors are designed with ferrules to hold and align the fiber when connecting, enabling light to transmit from one cable to another, or to active devices, testing equipment... Fiber optic connectors play a critical role in the reliability and performance of the networks they connect. High-quality connectors experience minimal light loss due to poor connection alignment or fiber misalignment.

2. Components of fiber optic connectors

Fiber optic connectors consist of several components, but the three main components are the ferrule, the connector housing, and the coupling mechanism.

- Ferrule: This is a thin, usually cylindrical structure used to hold the glass optical fiber. The center of the ferrule is hollow to secure the fiber in place tightly. Ferrules are typically made from ceramic, metal, or high-quality plastic and usually hold a single optical fiber.

- Connector housing: Also known as the connector body, this is the largest part of the fiber optic connector. It is a plastic or metal structure that holds the ferrule and attaches to the outer sheath of the cable, adding durability to the fiber optic components.

- Coupling mechanism: This part of the connector body secures the connector when attached to another device (such as a switch, NIC, or bulkhead coupler). It may be a clip, a bayonet-style nut, or a similar device.

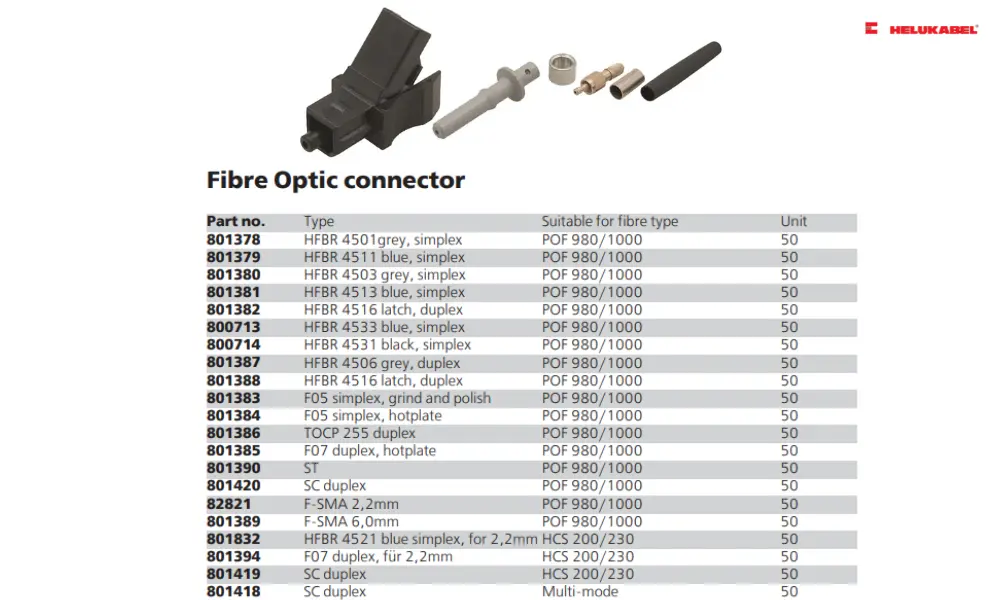

3. Common types of fiber optic connectors

3.1 LC connectors

LC connectors are a popular type of small form factor (SFF) connector. This interface was developed by Lucent Technologies, which is why it is called the Lucent Connector. The LC connector uses a latch mechanism similar to that of a telephone or RJ45 connector, and it has a square-shaped body. LC fiber optic connectors are typically held in a duplex configuration by a plastic clip. The ferrule in an LC connector has a diameter of 1.25mm.

3.2 ST connectors

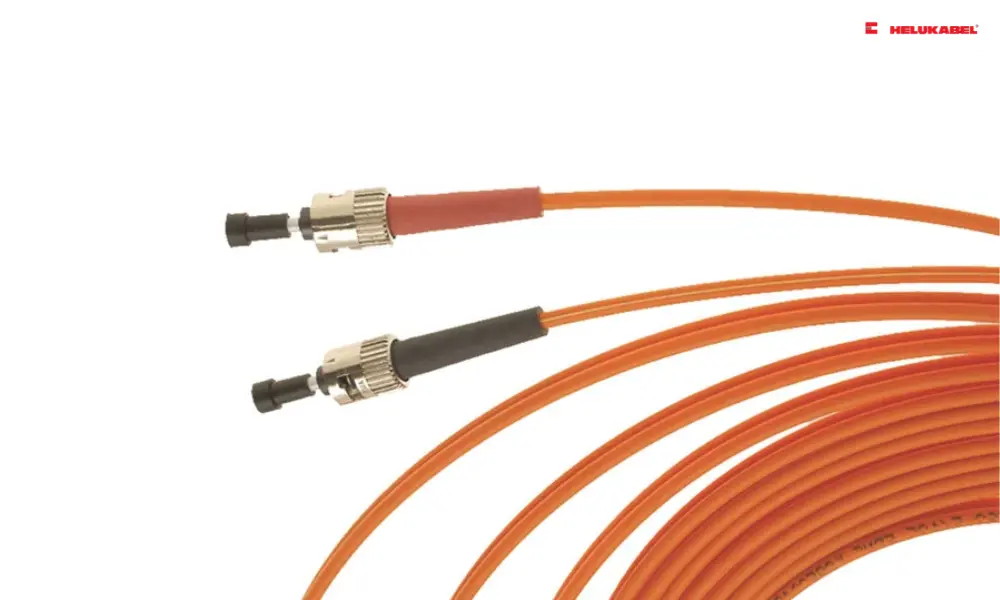

The ST (Straight Tip) connectors are one of the first widely used connectors in fiber optic networking applications. The ST connection uses a ferrule with a diameter of 2.5mm and has a round plastic or metal body. This connector is secured using a bayonet-style "twist-on/twist-off" mechanism. ST fiber optic connectors are commonly used in multimode fiber systems for campuses and buildings, enterprise network environments, and military applications.

3.3 SC connectors

The SC (Square Connector) also uses a 2.5mm round ferrule to hold a single optical fiber. This connector utilizes a "push-pull" connection mechanism, which is often easier to use in tight spaces compared to the twist-style of the ST connector. The SC connector body is square-shaped, and two SC connectors are often held together by a plastic clip (also called a duplex connection). Thanks to its excellent performance, the SC fiber connectors are commonly used in applications that require polarization maintenance. SC fiber connectors are well-suited for datacom and telecom applications, including point-to-point connections and passive optical networks.

3.4 FC connectors

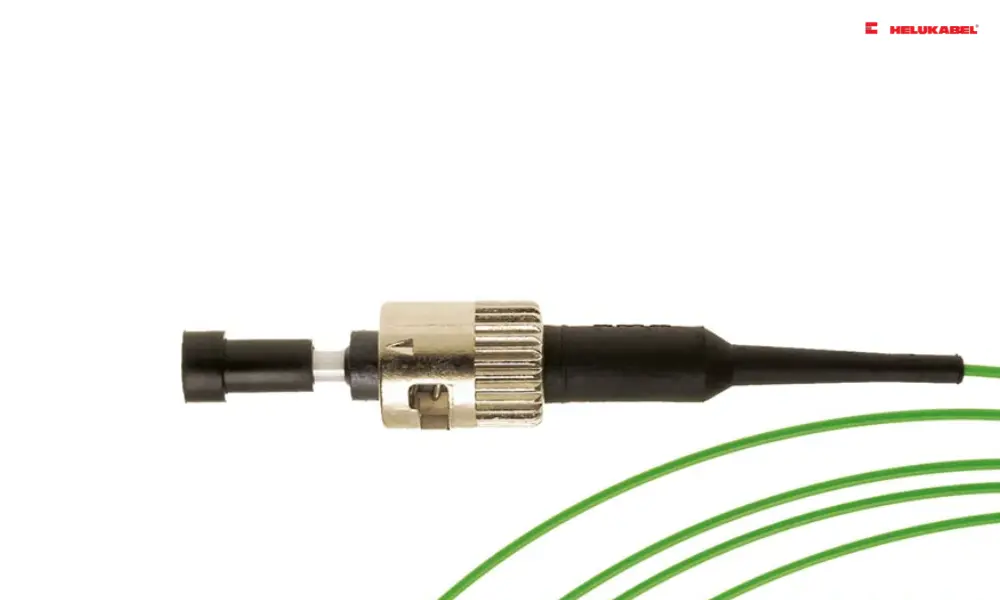

The FC (Ferrule Connector) is the first fiber optic connectors to use a ceramic ferrule. Unlike SC and LC connectors, which have plastic bodies, the FC connector uses a round, screw-type coupling made from stainless steel or nickel-plated metal. The end face of the FC connector relies on an alignment key for precise installation and is then tightened into the amplifier or jack with a threaded sleeve. Despite the added complexity in both manufacturing and installation, the FC connector remains a preferred choice for high-precision measurement equipment such as OTDRs, as well as for single-mode fiber applications. Similar to ST and SC connectors, the FC connector also uses a 2.5mm diameter ferrule.

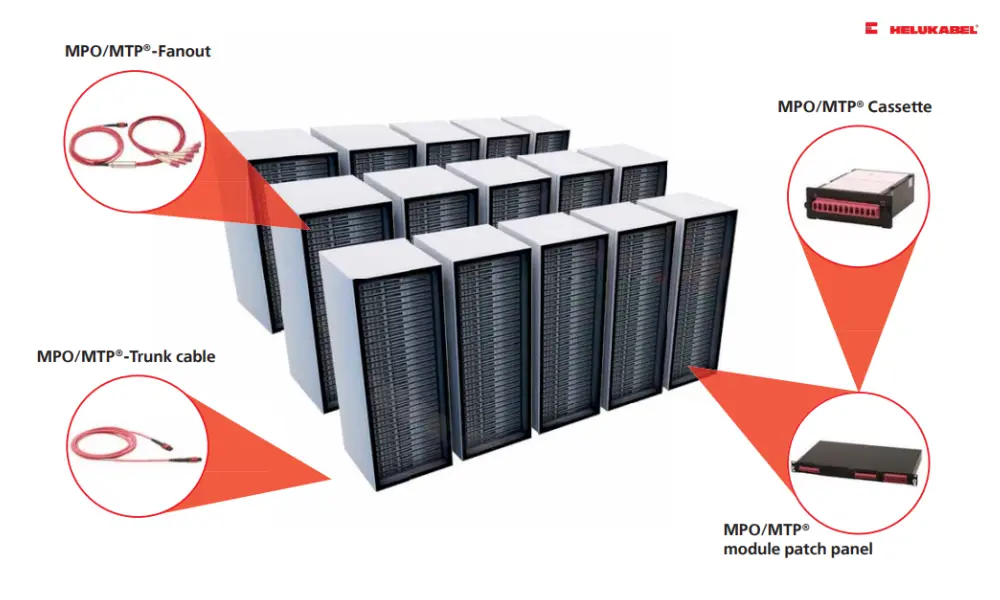

3.5 MPO/MTP fiber optic connectors

The MPO (Multi-Fiber Push-On) connectors are a fiber optic connector that can accommodate multiple fibers, typically available in configurations ranging from 4 to 144 fibers. It is commonly used in high-speed data centers and telecommunications applications. Integrating multiple fibers within a single connector significantly conserves space. The MTP connectors are an enhanced version of the MPO, designed with a removable housing and the ability to switch between male and female configurations. The MTP connection is secured with a push-pull latch mechanism and can be identified by a pair of metal guide pins protruding from the front of the connector.

4. A few notes prior to the selection of fiber optic connectors

4.1 Polishing styles: APC and UPC

When selecting fiber optic connectors, users should pay attention to the polishing type of the ferrules. Different polishing types are designed to enhance light transmission efficiency at connection points and minimize back reflection.

The main difference between APC (Angled Physical Contact) and UPC (Ultra Physical Contact) connectors lies in the end face of the optical fiber. The APC connectors have an 8-degree angle cut on the ferrule, creating a very tight connection between fibers. However, its return loss can reach up to -60 dB. Meanwhile, the UPC connectors have a convex end face with a smoother finish, offering a return loss ranging from -40 dB to -55 dB, making it reliable for transmitting TV and data signals. Additionally, APC fiber optic connectors are green, while UPC connectors are blue.

4.2 Single-mode and Multimode fiber optic connectors

The fundamental difference between Single-mode and Multimode fiber optic cables is the number of light modes that can be transmitted at once. Single-mode fiber allows only one light mode to pass through at a time, while Multimode fiber can transmit multiple light modes simultaneously. This distinction also applies to Single-mode and Multimode fiber optic connectors, as they are paired with their corresponding fiber types.

However, with advancements in technology, fiber optic connectors like SC, LC, and FC, provided by manufacturers, are now compatible with both Single-mode and Multimode fiber cables.

4.3 Simplex and Duplex fiber optic connectors

Simplex and duplex connections serve different purposes and are suitable for various applications, making it essential to understand their differences when choosing the appropriate fiber optic connector:

- For one-way communication: If your application only requires data transmission in one direction, a simplex connection is sufficient and often more cost-effective.

- For two-way communication: If your setup needs simultaneous data transmission in both directions, duplex connections are the suitable choice.

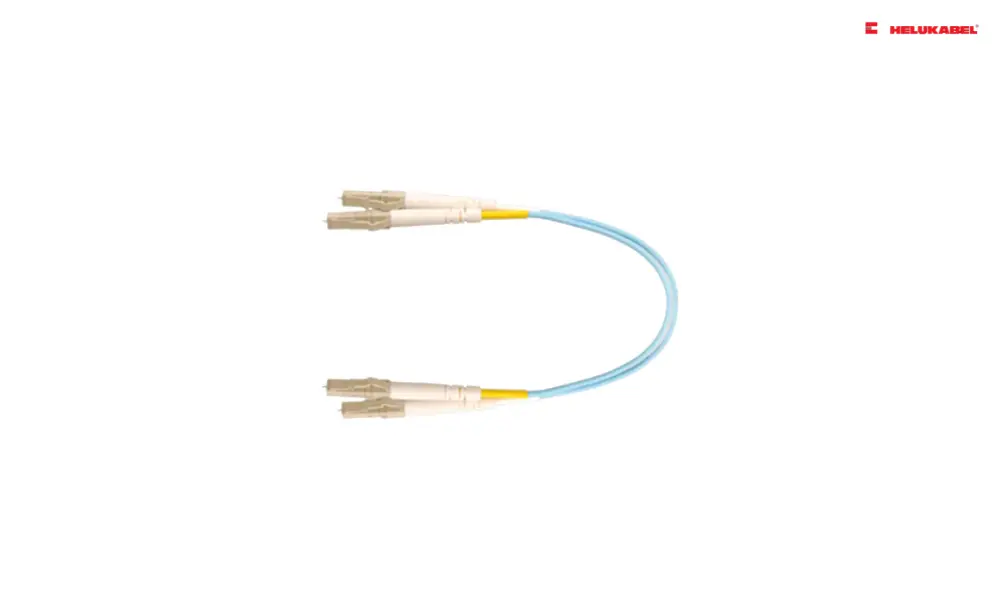

4.4 Fiber optic patch cords

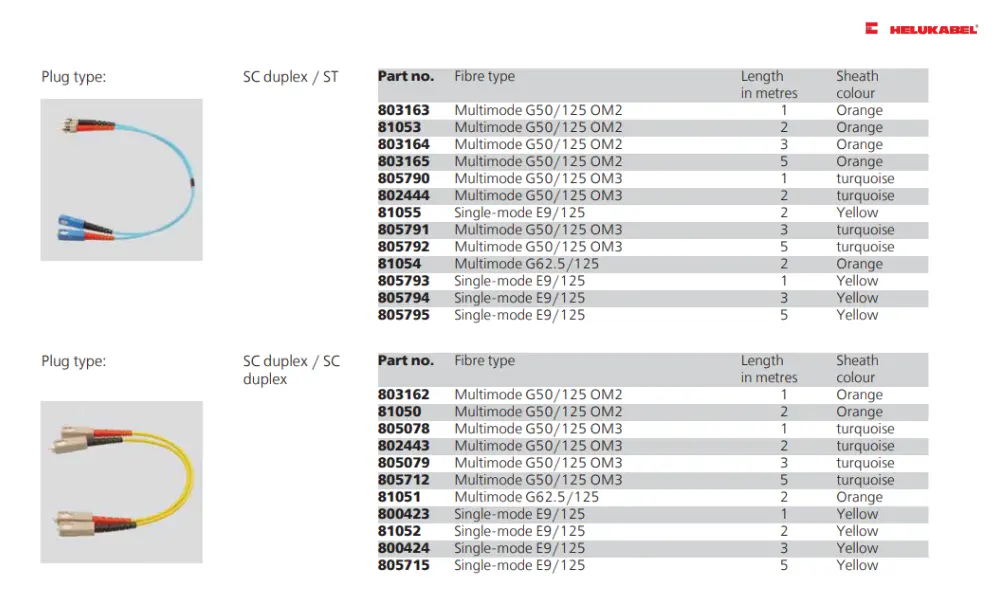

An essential application of fiber optic connectors is in fiber optic patch cords. A fiber optic patch cord is a pre-assembled fiber optic cable, available in various diameters and lengths, with connectors installed on both ends. Some common types of fiber optic patch cords include:

- LC-LC fiber connection: Known for its compact size, the LC-LC connection is ideal for dense network systems, helping to save space.

- LC-SC fiber connection: The small size of the LC connector makes it suitable for high-density setups, while the SC connector, with its push-pull locking system, ensures a secure connection. This combination provides flexible connectivity across different types of equipment.

- LC-ST fiber connection: LC connectors are suitable for high-density configurations, while ST connectors, with their round, bayonet-style coupling, offer reliability and ease of use. This setup is a flexible choice for various environments.

- SC-SC fiber connection: A patch cord with SC connectors on both ends ensures a stable connection and is commonly used in data centers.

- SC-ST fiber connection: This combines the secure push-pull style of the SC connector with the bayonet-style of the ST connector, providing flexibility and reliable performance across diverse network systems.

If you still have any concerns or questions about torsion-resistant cables, don't hesitate to reach out to HELUKABEL Vietnam's engineering team promptly for detailed assistance.

HELUKABEL® Vietnam

| Address | 905, Nguyen Kiem Street, Ward 3, Go Vap District, Ho Chi Minh City 700000, Vietnam |

| info@helukabel.com.vn | |

| Hotline | +84 28 77755578 |

| Website | www.helukabel.com.vn |

| Discover our products and place orders | Tiki | Product finder |

| Follow us on | Facebook | LinkedIn | Instagram | Youtube | Zalo | WhatsApp | Tiktok | Spotify |