PVC-Flat – Flexible and durable flat cable for reeling systems

Flat cables are often distinguished by their flexibility and durability, making them suitable for industrial applications, particularly in reeling operations. In this article, we’ll explore PVC-Flat cable – a type of cable recognized for its strong load-bearing capacity and adaptability to harsh conditions.

1. The roles of flat cables in reeling systems

As the name implies, the flat cable features a flat, rectangular shape. Its special structure offers many advantages over traditional round cables, giving it greater flexibility and easier bending, thus making it an ideal choice for applications that require constant movement. This feature not only extends the cable’s lifespan but also minimizes the risk of system damage, promoting reliable and long-term operation.

In addition, the flat structure of the cable also offers space-saving benefits, allowing easy installation in tight spaces, such as narrow trenches, pipes, or intricate mechanical systems. This design not only helps minimize space occupation but also enables a tidier and more organized wire layout.

Furthermore, thanks to its flat design, the flat cable can accommodate more conductors in a compact structure, optimizing the ability to transmit multiple signals at once while maintaining performance - especially in reeling systems where multiple connections are required over long distances.

2. PVC-Flat cable from HELUKABEL

PVC-Flat is one of HELUKABEL's outstanding flat cables. It is mainly used as a reeling cable for crane installations, floor conveyer systems and shelf control units. With excellent flexibility, space-saving design and reliable signal transmission, PVC-Flat cable has become an ideal solution for industrial applications.

2.1. Structure of PVC-Flat Cable

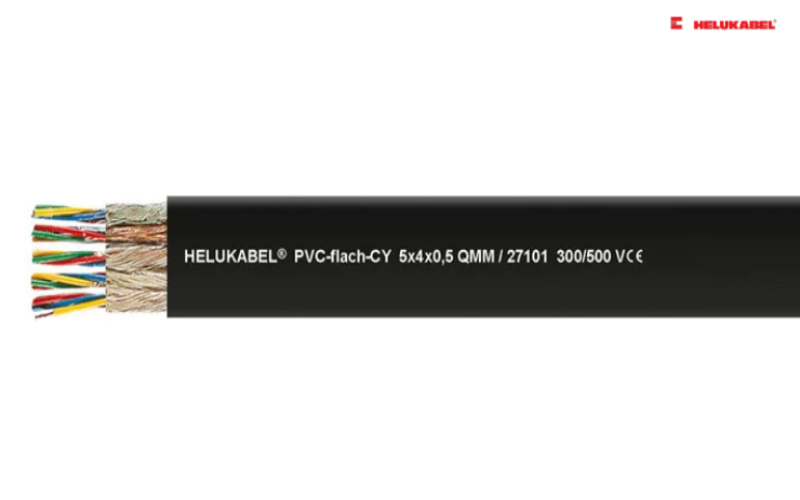

PVC-Flat cable is designed with a black outer sheath made from a specialized TM2-type PVC compound. Its conductor is made of bare copper, meeting the DIN VDE 0295 Class 5 standard, while the conductor insulation is made from a TI2-type PVC compound.

This cable comes with various core options, ranging from 4 to 20 cores, and cross-sections from 0.75 to 70 mm². Unlike round cables, where cores are twisted together, the cores in PVC-Flat cable are arranged parallel to each other in a defined sequence. For cables with 5 cores or fewer, each core is color-coded for easy identification. For cables with 7 cores or more, the core numbers are printed continuously in white on the black insulation.

A distinctive feature of the PVC-Flat cable structure is the green-yellow conductor. This protective wire enhances the cable's safety, ensuring electrical protection throughout the system’s operation.

2.2. Technical specifications and properties

PVC-Flat cable complies with EN 50214 and DIN VDE 0283-2 standards. It operates within a temperature range of approximately -5°C to +70°C for flexing applications and -40°C to +80°C for fixed installations.

The cable's nominal voltage depends on cross-sections. Specifically, the one with a cross-section of 0.75 mm² and 1 mm² has a nominal voltage of U0/U 300/500 V. Meanwhile, for the one with a cross-section of 1.5 mm² or more, it is U0/U 450/750 V.

Thanks to its extremely small bending radius, this cable is extremely suitable for reeling systems. Accordingly, the minimum bending radius is 10 times larger than the cable’s outer diameter, showing high flexibility, thereby reducing wasted system space.

In addition, PVC-Flat cable is designed to withstand mechanical stress during continuous winding and unwinding, preventing twisting or tangling in operation. It also has a packeting possibility, which means it can allow data packets to be transmitted efficiently and reliably, ensuring data integrity and minimizing latency.

Also, the cable’s resistance to oils, chemicals, and radiation (up to 80 Mrad) makes it suitable for harsh environments without sacrificing performance. Furthermore, the PVC material used in these cables has been tested to meet VDE, EN, and IEC standards for self-extinguishing and flame-retardant properties, which is crucial for reducing risks in case of fire or explosion.

Due to the specialized design of PVC-Flat cable, installation must follow specific guidelines, including cable placement, trolly placement on guiding rails or upon carrier beams, and other requirements to ensure safe and effective operation.

3. Other similar flat cables from HELUKABEL

In addition to PVC-Flat, HELUKABEL offers a wide range of flat cable options to meet the diverse needs of various industries. Notably, PVC-Flat-CY cable is an enhanced version of PVC-Flat cable, providing superior oil resistance and interference protection.

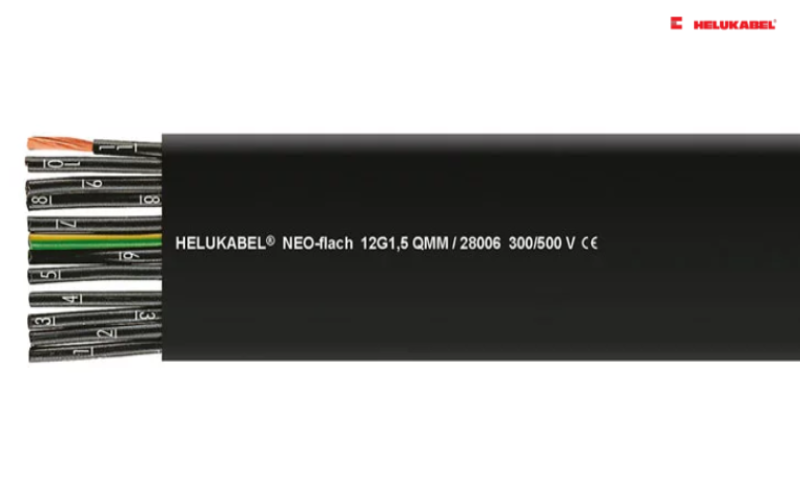

For demanding applications, NEO-Flat cable, made from durable Neoprene, is ideal for use as reeling cables in crane installations, floor conveyer systems and shelf control units. Especially, the NEO-Flat-C version includes an additional anti-interference layer to ensure uninterrupted signal transmission.

We hope this article has provided you with a solid overview of PVC-Flat cable and its advantages in reeling systems. For further assistance with any of the products mentioned, please reach out to the HELUKABEL Vietnam engineering team!

HELUKABEL® Vietnam

| Address | 905, Nguyen Kiem Street, Ward 3, Go Vap District, Ho Chi Minh City 700000, Vietnam |

| info@helukabel.com.vn | |

| Hotline | +84 28 77755578 |

| Website | www.helukabel.com.vn |

| Discover our products and place orders | Tiki | Product finder |

| Follow us on | Facebook | LinkedIn | Instagram | Youtube | Zalo | WhatsApp | Tiktok | Spotify |