What are temperature-resistant cables? Their features and applications

When conditions become more extreme, temperature-resistant cables perform at their best. Designed to withstand intense heat without compromising performance, these cables are the perfect example of durability and reliability.

When choosing electrical cables, the impact of temperature on performance is a critical factor that must be carefully considered. Along with conditions such as weather, indoor or outdoor environments, dry or humid settings, whether the cable is mounted, laid in conduits, or buried directly, both hot and cold temperatures have a significant effect on the cable's performance. Using the wrong type of cables can result in severe consequences for its functionality in extreme temperatures.

1. The importance of temperature-resistant cables

1.1 The impact of extreme temperature on cables

High temperatures often cause electrical cables to overheat. Specifically, as the temperature rises, the resistance of the conductor inside the cable increases due to the expansion of the material, making it more difficult for the current to flow and reducing the overall efficiency of the cable. In extreme cases, it could even lead to complete failure of the cable. This effect is more pronounced in cables with aluminum conductors, such as those used in overhead power lines.

The insulation of the cable is also on the verge of being damaged by heat. When the temperature becomes too high, the insulation may melt, posing a risk of electric shock or fire. If the appropriate heat-resistant cables are not used, this phenomenon is more likely to occur during extremely hot summers. However, the impact of overheating is even more serious in industrial environments, where cables are often exposed to extremely high temperatures. In these cases, only cables with special insulation that can withstand extreme temperatures can ensure safe and efficient operation.

Extremely cold temperatures also negatively affect electrical cables. Firstly, cold temperatures cause the conductor of the cable to lose heat, which reduces its efficiency. Another vulnerability when cables are exposed to cold temperatures is a reduction in their flexibility, which can lead to breakage. Some insulation materials, such as ordinary PVC, may become rigid and brittle when exposed to cold weather.

1.2 What are temperature-resistant cables?

In many industrial applications, electrical cables are often exposed to extremely high or low temperatures. This can lead to damage and unstable equipment performance, resulting in costly production interruptions. To meet these demands, temperature-resistant cables have been specifically designed and manufactured to withstand temperature fluctuations, ensuring more stable and reliable operation.

Temperature-resistant cables are specially developed for use in extreme temperature conditions. In high-heat production environments, these cables provide optimal safety. They are specifically designed for harsh areas and deliver outstanding performance wherever high temperature resistance is required, combined with flexibility, such as in drag chains with long travel distances.

2. Applications of temperature-resistant cables

Temperature-resistant cables are used in various industries with numerous demanding applications, including:

- Refrigeration technology, air conditioning, or the maritime industry

- Temperature-resistant cables are primarily used for equipment and machinery that face high temperatures daily. For instance, in offshore or port areas, cables used for cranes must withstand not only UV exposure but also high temperatures from direct solar radiation.

- Fields such as metallurgy, steel mills, rolling mills, cement production, glass manufacturing, and ceramics…These industries operate in environments with extremely high temperatures.

- Other industries are exposed to external environmental factors such as agriculture, construction, and many others.

Whether in hot or cold conditions, the functionality and reliability of the cables must be as consistent as they are under normal ambient temperatures.

3. Features of materials used in temperature-resistant cables

Depending on the requirements and the application area, various materials are selected to best meet the necessary characteristics within the required temperature range and specific applications. These materials include XLPE, silicone, FEP, PTFE, glass silk…

| Material | Features | Temperature range |

| XLPE | Temperature-resistant cables made from XLPE are halogen-free and not listed under restricted substances as per RoHS standards. | -35°C to 90°C |

| Silicone | Silicone offers not only temperature resistance but also exceptional flexibility, making it suitable for a wide temperature range. | -60°C to 180°C |

| FEP | Fluorinated ethylene propylene (FEP) exhibits superior characteristics like chemical resistance, solvent resistance, and vapor resistance, suitable for diverse environments. | -100°C to 205°C |

| PTFE | A highly versatile material widely used in many industries due to its stable, durable, corrosion-resistant, and chemically resistant properties, as well as its ability to withstand extreme temperatures. | -190°C to 260°C |

| Glass silk | Glass silk cables are characterized by their high temperature resistance, enduring extremely high temperatures without degrading, making them ideal for extremely hot environments. With their inorganic composition and high melting point, fiberglass can typically withstand temperatures up to approximately 700°C or higher depending on the specific type. | Up to 700°C |

4. HELUKABEL’s temperature-resistant cables

HELUKABEL manufactures and supplies a wide range of temperature-resistant cables, designed to meet the needs of diverse applications.

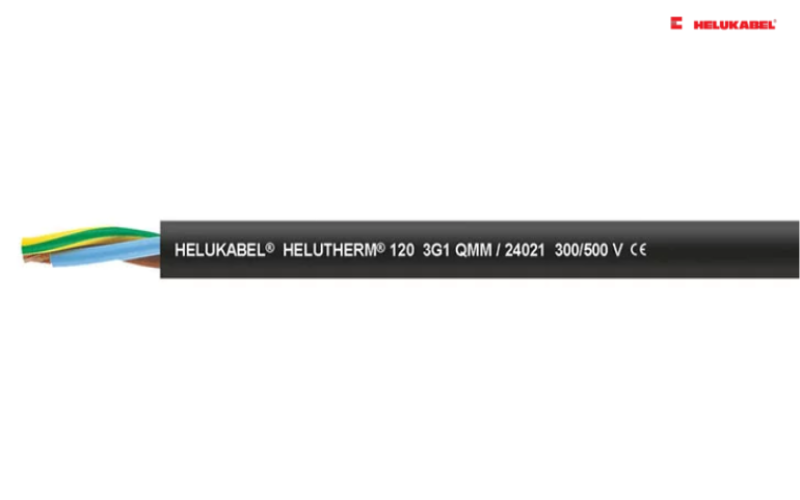

4.1 HELUTHERM temperature-resistant cables

For applications requiring temperature resistance up to 145°C, users can consider HELUTHERM® heat-resistant cables, including the HELUTHERM® 120, HELUTHERM® 145, HELUTHERM® 145 MULTI, and HELUTHERM® 145 MULTI-C variants. These cable lines feature exceptional fire resistance and are used for connecting lighting systems, heaters, electrical machinery, switchgear, and distribution systems.

Besides, users may explore two UL/CSA-certified products: HELUTHERM® 145 UL/CSA 300V and HELUTHERM® 145 UL/CSA 600V . These temperature-resistant cables are designed for internal wiring in lighting systems, heating units, electrical machinery, switchgear, and distribution components in industrial equipment as well as in plant and industrial construction.

4.2 HELUPOWER® THERMFLEX® temperature-resistant cables

HELUPOWER® THERMFLEX® temperature-resistant cables come in many variants such as HELUPOWER® THERMFLEX® 145, HELUPOWER® THERMFLEX® 145-C, HELUPOWER® THERMFLEX® 145-Single. These are single core cables, used as generation connection cables in wind power plants and other applications requiring high current capacity. They are advantageous due to reduced outer diameter, making them suitable for confined installation spaces.

Other applications include: thermal class B (130°C) connection cables for motors, transformers, relays, coils, and magnets; power supply connections in the automotive industry; halogen-free cables for control and distribution cabinets; connection cables for heating devices; power cables for high-performance lighting in industrial areas, sports facilities, and transportation infrastructure; cables for charging stations and pantographs in e-Mobility applications.

4.3 Silicone temperature-resistant cables

Some of HELUKABEL's silicone temperature-resistant cables include:

- SiHF and SiHF-C-Si: Temperature-resistant cables with tinned copper braiding, capable of withstanding low temperatures down to -60°C. These cables are particularly suitable for installation in power plants, steel manufacturing industries, aviation, shipbuilding, and factories producing ceramics, glass, and cement.

- SiHF UL/CSA and SiHF-C-Si UL/CSA: Certified to UL/CSA standards, these cables are developed for export-oriented machine manufacturers, specifically targeting markets in the United States and Canada.

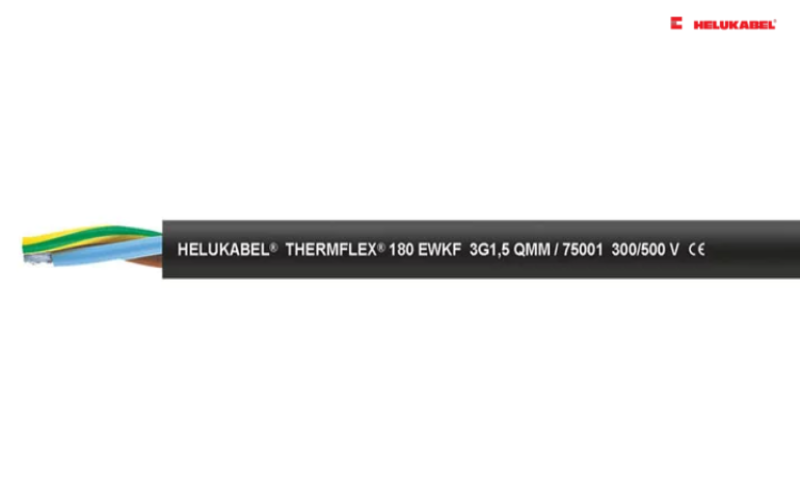

- THERMFLEX® 180 EWKF and THERMFLEX® 180 EWKF-C: Ideal for applications requiring enhanced mechanical durability. Common uses include air conditioning and heating systems, saunas, and solariums, as well as in foundries, steel, cement, and ceramic factories, kilns, and lighting equipment.

HELUFLON®-FEP-6Y (above) and HELUFLON®-PTFE-5Y (below)

4.4 FEP and PTFE temperature-resistant cables

The HELUFLON®-FEP-6Y and HELUFLON®-PTFE-5Y temperature-resistant cables are primarily used for installation in high-temperature control cabinets, as well as in brick factories, heating equipment, kitchen appliances, and measuring devices. They are also widely applied in the chemical industry. These cables are non-flammable and resistant to acids, alkalis, solvents, oils, and gasoline.

Technical data of HELUFLON®-FEP-6Y, single core

4.5 Glass silk cables

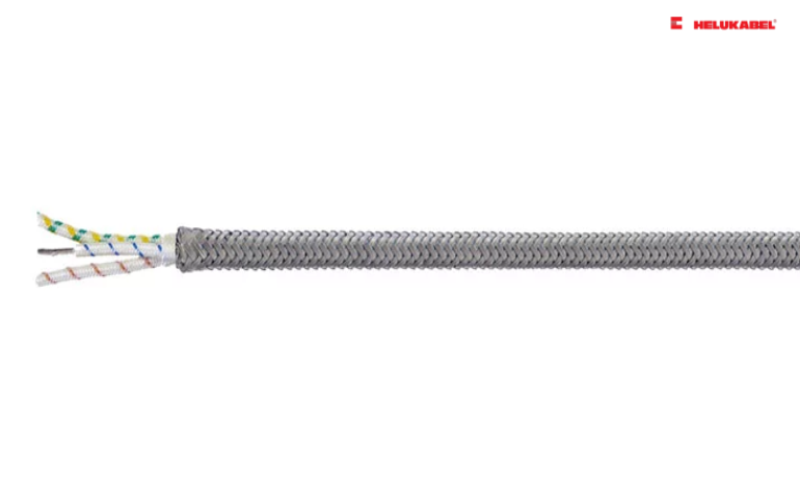

These are high-performance temperature-resistant cables designed for extreme temperature applications, including:

- HELUTHERM® 400-MULTI and HELUTHERM® 400-MULTI-ES: Suitable for applications requiring extremely high connection and ambient temperatures, such as metallurgical, steel, and rolling mills, foundries, glass and ceramic plants, furnace construction, power plants, and thermoplastic processing. These cables are intended for use in dry environments only.

- HELUTHERM® 400: Features a nickel conductor and a wide temperature range. It is especially suitable for aerospace applications, power plants, motor design, and chemical, steel, and metallurgical industries.

- HELUTHERM® 600: Designed for applications with extremely high connection and ambient temperatures, such as electrical heating elements, furnaces, and thermoplastic molding processes. This cable offers excellent resistance to moisture and chemical impacts.

- HELUTHERM® 600-ES: A high-quality armored version that protects the cable against harsh environments and mechanical impacts. The armored sheath not only provides physical protection but also adds an aesthetic appearance and can be used for grounding purposes.

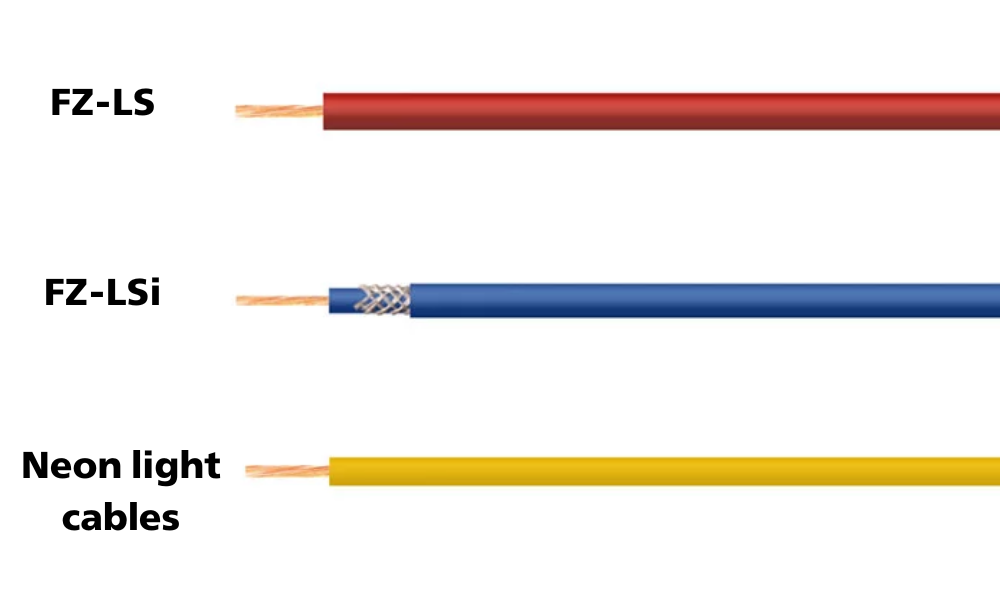

4.6 FZ-LSi / FZ-LS / Neon Light Cables

Other types of HELUKABEL's temperature-resistant cables include:

- FZ-LSi, blue: This ignition cable is suitable for use at high and extremely alternating ambient temperatures up to +180°C. Applications include engine manufacturing, valve manufacturing and heating technology. As protection against mechanical damages a glass fibre braiding and a silicone sheath covers the core insulation.

- FZ-LS, red:This ignition cable is suitable for use at high and extremely alternating ambient temperatures up to +180°C. Applications include the lamp and lighting industry and cooling and airconditioning technology.

- Neon-light-cable, yellow: This cable is primarily suitable for use at high and extremely alternating ambient temperatures such as in the lamp and lighting industry. Protected installation is required.

If you still have any concerns or questions about temperature-resistant cables, don't hesitate to reach out to HELUKABEL Vietnam's engineering team promptly for detailed assistance.

HELUKABEL® Vietnam

| Address | 905, Nguyen Kiem Street, Ward 3, Go Vap District, Ho Chi Minh City 700000, Vietnam |

| info@helukabel.com.vn | |

| Hotline | +84 28 77755578 |

| Website | www.helukabel.com.vn |

| Discover our products and place orders | Tiki | Product finder |

| Follow us on | Facebook | LinkedIn | Instagram | Youtube | Zalo | WhatsApp | Tiktok | Spotify |