Cables for Single Pair Ethernet: Where Are We Headed?

Which SPE solutions are preferable against existing communication standards?

1. What is Single Pair Ethernet (SPE)?

Single Pair Ethernet (SPE) is being seen as one of the major trends shaping the future of industrial communication. This new connection technology, with only a single pair of conductors, brings numerous advantages such as high-speed data transmission, space savings, and reduced costs.

Currently, various communication systems are in use within industrial environments, such as Profinet, CAT 5e and 6a, Industrial Ethernet, or EtherCAT. However, Single Pair Ethernet has the potential to replace these technologies in many applications, thanks to its ability to transmit gigabit-speed data and supply power simultaneously through a single pair of wires. This is a smart, flexible, cost-effective, and space-saving solution that enables real-time communication down to field devices.

Single Pair Ethernet (SPE) is a technology for transmitting data over wired networks. Data cables using SPE technology differ from previous types by needing only one pair of copper wires. Previously, PROFINET cabling required two pairs of wires, while Gigabit Ethernet required four pairs. Additionally, SPE enables simultaneous power transmission over the same pair of wires, known as Power over Data Line (PoDL). This makes the cables slimmer and lighter, providing numerous benefits and opening up new applications in the future.

2. Advantages of Single Pair Ethernet Technology

The Single Pair Ethernet (SPE) is gradually affirming its position as an advanced technology in industrial communication, offering superior benefits over traditional Ethernet solutions. Here are the key advantages that SPE technology brings to businesses and modern industrial applications:

2.1 Slim, lightweight, and flexible cable design

SPE Ethernet cables require only a single pair of conductors, saving space, reducing weight, and allowing easy installation even in tight spaces. The high flexibility of SPE cables makes them ideal for applications that require compact cables without compromising on optimal performance.

2.2 Cost and resource savings

Thanks to its simpler design and fewer conductors, SPE Ethernet cables reduce purchase and installation costs compared to previous Ethernet systems. Additionally, using fewer materials translates into resource savings, contributing to environmental protection.

2.3 High-speed, stable data transmission

SPE supports data transmission speeds of up to 1 Gbit, efficiently meeting the demands for high-speed data transfer in industrial applications. This advantage optimizes system performance and ensures stability in operation.

2.4 Wide transmission range

SPE Ethernet cables can transmit data up to 1,000 meters when using AWG 18 wire, enabling stable long-distance connectivity. This feature is particularly beneficial in large plants or systems where devices need to communicate across significant distances.

2.5 Real-time communication to field-level devices

With its support for real-time communication, SPE enables data transfer directly to field-level devices, ensuring that information is updated quickly and accurately to meet operational efficiency demands.

2.6 Excellent bending radius for mobile applications

SPE cables have a small bending radius, making them suitable for applications that require flexible cabling, such as robotic arms or mobile devices in production lines.With these exceptional advantages, Single Pair Ethernet not only offers cost-effectiveness but also opens up new application possibilities, allowing businesses to improve processes and sustainably enhance productivity. This technology is becoming a top choice for modern factories and industrial systems.

3. Applications of Single Pair Ethernet (SPE)

Single Pair Ethernet (SPE) originated in the automotive industry, where space-saving and weight reduction are crucial factors. However, other industries are now also aiming to leverage the benefits of SPE, particularly in applications that require high data transmission speeds.

For the first time, this technology enables comprehensive automation down to the device level, integrating sensors, actuators, and other devices into a unified system. Previously, these devices typically connected to control systems via fieldbus, which is separate from the Ethernet network. SPE bridges this gap, and with its ability to deliver real-time communication down to the field level, it’s seen as a pivotal technology for the Industrial Internet of Things (IIoT) and Industry 4.0.

SPE’s ability to streamline connectivity across the industrial automation pyramid makes it a valuable asset for industries looking to improve efficiency and implement advanced, interconnected systems.

4. Features of SPE

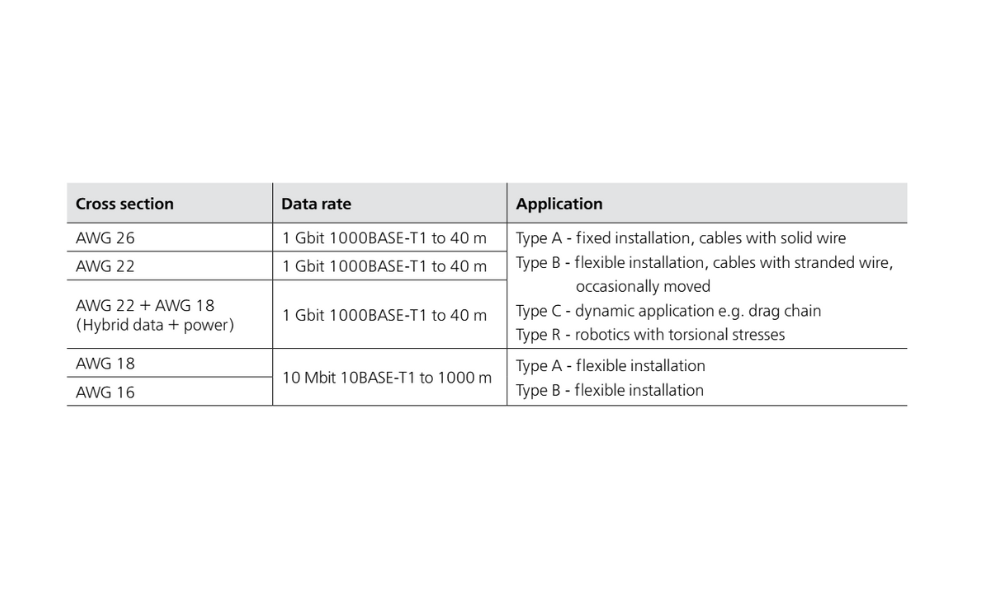

4.1 Cable classification for SPE

A basic prerequisite for the use of SPE is to have the right technical infrastructure in place - from terminals and plug connections to cabling. In order to make the changeover easier for manufacturers and users, the same cable classifications were defined for SPE as are already used for Profinet:

- Type A: wires with solid wire for permanent installation

- Type B: wires with stranded conductors for flexible applications or vibrations

- Type C: wires with stranded conductors for high dynamic applications (such as drag chains)

- Type R: torsion tested cables with stranded conductors for robotic applications

Drag chain and robot cables mainly differ by their respective screening designed for bending or torsional load capacity.

4.2 Properties of different sheath materials of SPE cables

In addition, different sheath materials are used for each cable type to suit specific applications. Cables of type A and B are typically screened with PVC. There are also plenty of halogen-free, food safe and oil and chemical resistant alternatives to choose from. Type C cables are available in PUR, PVC and Santoprene, and type R robot cables are also available in PUR and Santoprene.

| Jacket | Halogen-Free | Flame Retardancy | Low Smoke | Price | Oil Resistance | Repeated Bending | Abrasion Resistance | UL Flame Test Possibilities |

| PVC UL | No | Medium-high | No | Low-medium | Low-high | Medium | Medium | VW1, FT1, FT4 |

| FRNC/LS0H/ LSZH | Yes | Medium-high | Yes | Medium | Low | Low | Low | VW1, FT1, FT4 |

| PE | Yes | No | Yes | Medium | Low | Low | Low | No |

| PUR UL | Yes | Medium | Medium | High | High | High | High | VW1, FT1, CFT |

| TPE (Santoprene) | No | Medium | medium | High | High | High | High | VW1, FT1, CFT |

| TPE (Santoprene) | Yes | No | Medium | High | High | High | High | No |

Table 1: Properties of different sheath materials of SPE cables

4.3 Data transmission of SPE

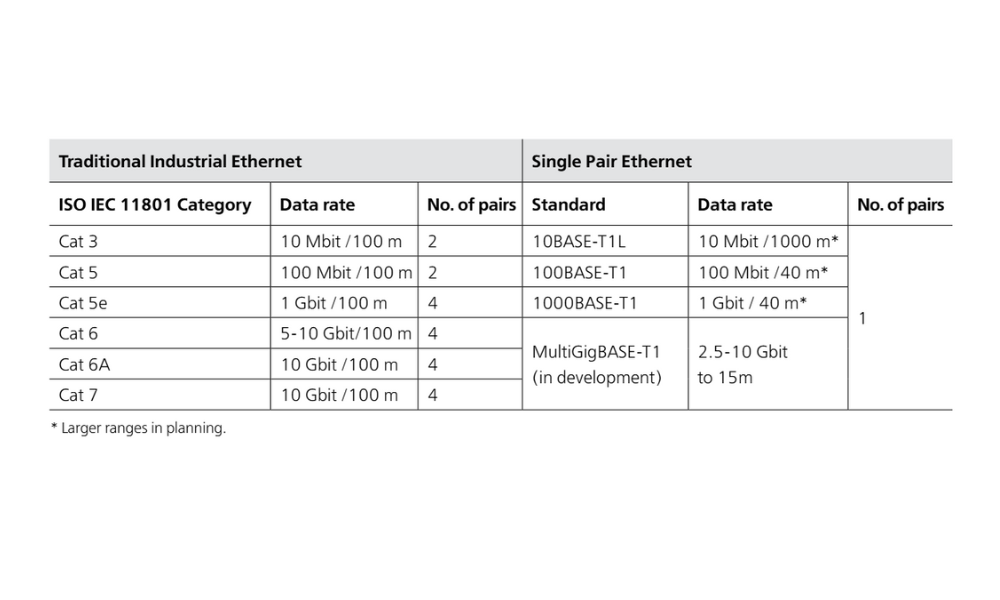

For data transmission, Single Pair Ethernet offers several options in terms of speed and range:

- 10BASE-T1: data rate up to 10 Mbit/s, range up to 1.000 m

- 100BASE-T1: data rate up to 100 Mbit/s, range up to 40 m

- 1000BASE-T1: data rate up to 1 Gbit/s, range up to 40 m

- MultiGigBASE-T1: data rate up to 2,5 / 5 / 10 Gbit/s, range up to 15 m

In the industrial environment, 10BASE-T1 and 1000BASE-T1 are currently the most important. The MultiGig technology, which is still being developed, will open more possibilities in the future. HELUKABEL has already added three different SPE cables for 10BASE-T1 and 1000BASE-T1 to its portfolio, and the product range is constantly being expanded.

5. Comparing different industrial communication technologies with SPE

5.1 Comparing SPE 10BASE-T1 with Profibus PA

When comparing different existing industrial communication technologies with Single Pair Ethernet, many advantages become apparent depending on the application. For example, 10BASE-T1 scores more highly than Profibus PA with its significantly higher frequency range, which enables a data transmission at up to 320 times the speed - fast enough for the transmission of videos, for example.

| Profibus PA / Foundation Fieldbus | SPE 10BASE-T1L | |

| Cross Section | AWG 18 solid or stranded / AWG 16 stranded | |

| Max. Distance | up to 1900 m non harzardous areas, up to 1000 m in hazardous areas (FISCO Power Supply to IEC 60079-11) | up to 1000 m (TI phy DP83TD510E > 2000 m Peer-to-Peer) |

| Impedance | 100 +- 20 ohms @ 31,25 kHz | 100 +- 15 ohms @ 20 MHz |

| Frequency Range | up to 39 kHz | up to 20 MHz |

| Max. Data Rate | 31,25 kbit | 10 Mbit |

| Typical Connector | M12 a-coded 4 PIN IP67 7/8 inch PI67 | M8/M12 SPE IEC 63171-6 |

Table 2: Comparison of SPE 10BASE-T1 with Profibus PA

5.2 Comparing SPE 1000BASE-T1 and Profibus DP

Compared to USB technology, both 1000BASE-T1 and MultiGigBASE-T1 offer a significantly higher data rate and range as well as a greater power supply. 1000BASE-T1 is also preferable due to its smaller cable diameter and lower weight, lower copper requirement and tighter bending radii than cabling with Profibus DP, CAN or Industrial Ethernet.

| Comparison | Profibus DP | SPE 1000BASE-T1 | SPE 1000BASE-T1 | SPE Advantage or Disadvantage |

| Drag Chain Design | Drag Chain Design | Drag Chain Design | ||

| Cross Section | AWG 23/19 | AWG 26/19 | AWG 22/19 | |

| Data Rate | 12 Mbit | 1 Gbit | 83x more data rate | |

| Cable Diameter | 8,0 mm | 4,9 mm | 6,3 mm | 21-38% reduced space |

| Max. Distance | 100 m* | 40 m | disadvantage in length | |

| Power | no(hybrid) | PoDL up to 50 W | power included | |

| Cable Weight | ~ 77 kg/km | ~ 29 kg/km | ~ 50 kg/km | 35-60% reduced weight |

| Copper Fig. | 25 kg/km | 16 kg/km | 24 kg/km | 4-36 % reduced copper |

| Bending Radius Chain | 96 mm | 59 mm | 76 mm | 20-39% red. bending radius |

*with high speed 12 Mbit

Table 3: Comparison of SPE 1000BASE-T1 with Profibus DP

>>Find out more: Information about plastic drag chain

6. Classifications of SPE cables

To simplify the introduction of Single Pair Ethernet (SPE) technology to users, several standards have been established. Depending on the range and data transmission speed, SPE is categorized into different types, similar to previous industrial Ethernet solutions.

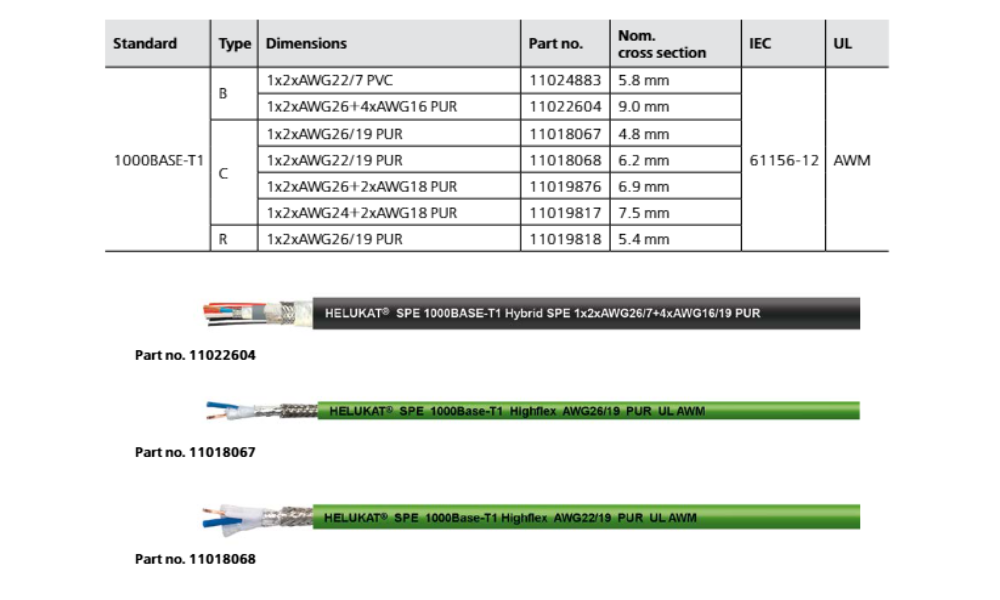

HELUKABEL currently offers several cable types specifically designed for Single Pair Ethernet technology. Below are the available products:

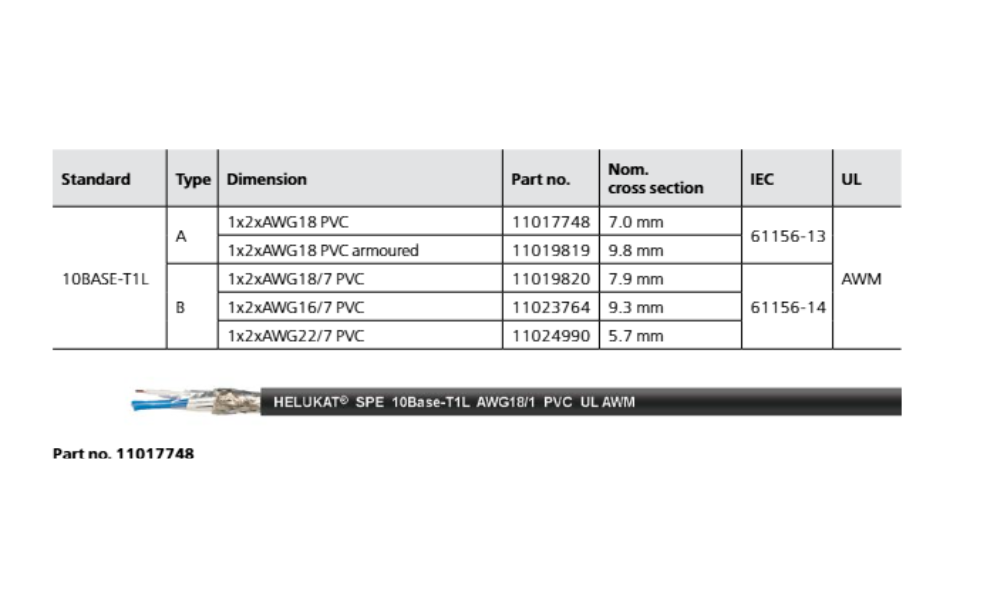

- 11017748 – SPE 10BASE-T1L – for fixed installation

- 11018067 – SPE 1000BASE-T1 – AWG26 – for drag chains

- 11018068 – SPE 1000BASE-T1 – AWG22 – for drag chains

7. HELUKABEL cables for SPE technology

HELUKABEL has been a member of the SPE Industrial Partner Network since 2019. This association, headquartered in Rahden, Westphalia, is a consortium of companies that work together to promote Single Pair Ethernet technology and advocate for uniform standards. The platform now has 52 participating members.

As a premium member of the SPE Industrial Partner Network and a member of the Technical Working Group, HELUKABEL plays a crucial role in advancing SPE technology. The primary goal is to develop a standardized infrastructure that makes the transition to Single Pair Ethernet easier for both manufacturers and users.

HELUKABEL offers a range of cables designed specifically for Single Pair Ethernet, catering to various industrial applications, ensuring both performance and reliability across different use cases.

7.1 Ethernet SPE cables for industrial automation

Some ethernet cables for industrial automation include:

- HELUKAT SPE 1000BASE-T1 Hybrid SPE

- HELUKAT SPE 1000BASE-T1 Highlex AWG 26/19

- HELUKAT SPE 1000BASE-T1 Highlex AWG 22/19

7.2 Ethernet SPE cables for process automation

With the 10BASE-T1L technology, SPE brings a significant leap forward in process automation. Previously, data transmission speeds in this field only reached 31.25 kBit, but SPE 10BASE-T1L can transmit data at speeds of up to 10 Mbit, enabling video transmission from security cameras over a maximum range of up to 1000 meters (which Profibus PA cannot achieve).

You can find out more information in the "Single Pair Ethernet (SPE) Cabling" webinar that HELUKABEL recently did as part of the SPE Industrial Partner Network's "SPE Pioneer Summit" series. HELUKABEL expert Horst Messerer delivers a detailed presentation about the advantages of SPE technology compared to existing communication standards and explains which cables and connectors are already available on the market. The webinar can be accessed free of charge at any time here .

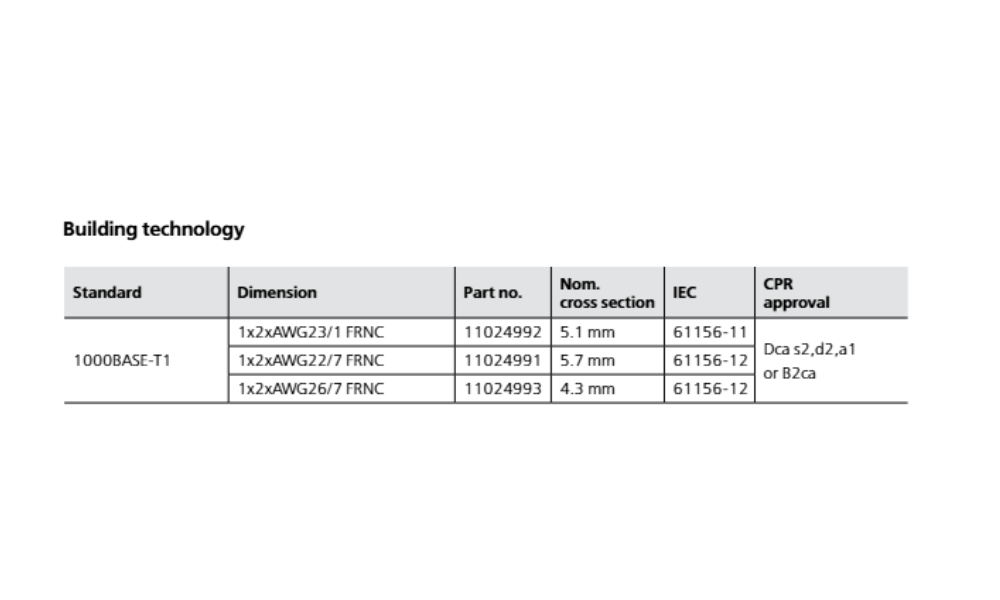

7.3 Ethernet SPE cables for building technology

In addition to the options for expanding or replacing SPE in traditional sensor cable systems and industrial Ethernet, in the future, SPE could also be applied with the CAN bus system, supporting SPE 1000Base-T1 over a range of up to 40 meters. This not only helps reduce weight but also significantly increases data transmission speeds.