DC cables and AC cables: Solutions for photovoltaic systems

DC cables and AC cables are designed to address specific purposes, connecting various components within a solar power system.

1. Understanding DC cables and AC cables

1.1 What are DC cables?

Electrical power can be classified as either Alternating Current (AC) or Direct Current (DC) based on the direction of energy flow. DC is a unidirectional current that moves in a straight line. DC cables are designed to transmit electrical power in the form of direct current. Many electronic devices and appliances, such as lights, refrigerators, and washing machines, as well as solar panels, fuel cells, and certain types of generators, utilize DC power. DC current can be generated from AC electricity using a rectifier converter.

1.2 What are AC cables?

Alternating current (AC) is a type of electrical current in which the direction of flow and polarity periodically reverse over time. Most power grids operate using AC because generators typically work on the principle of an AC generator, which produces alternating current when the stator coil rotates within a magnetic field. AC transmission is widely preferred because its voltage can be easily adjusted using a transformer, making it suitable for a wide range of applications. AC cables are commonly used to transmit electricity over long distances and in commercial buildings.

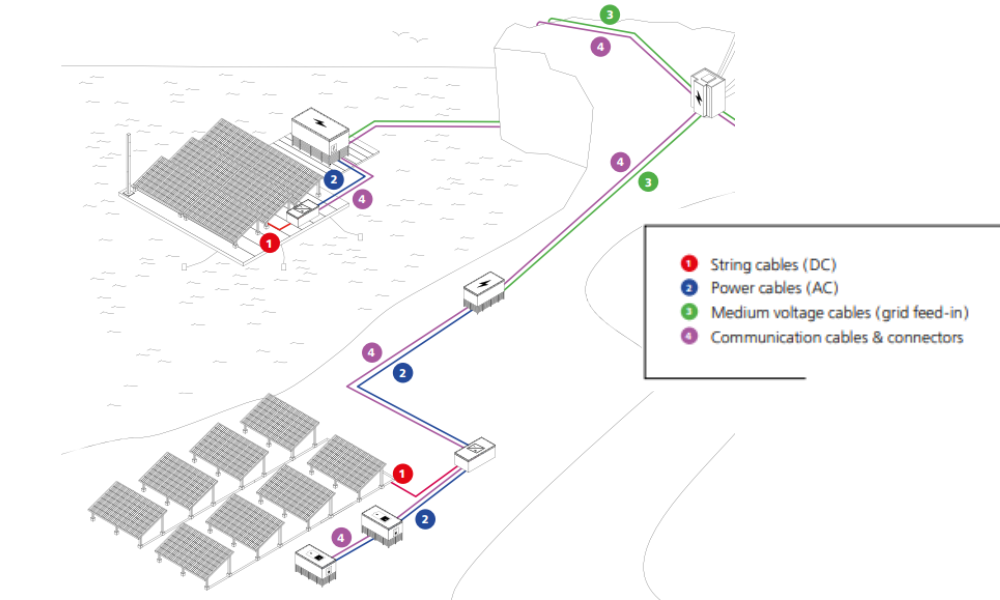

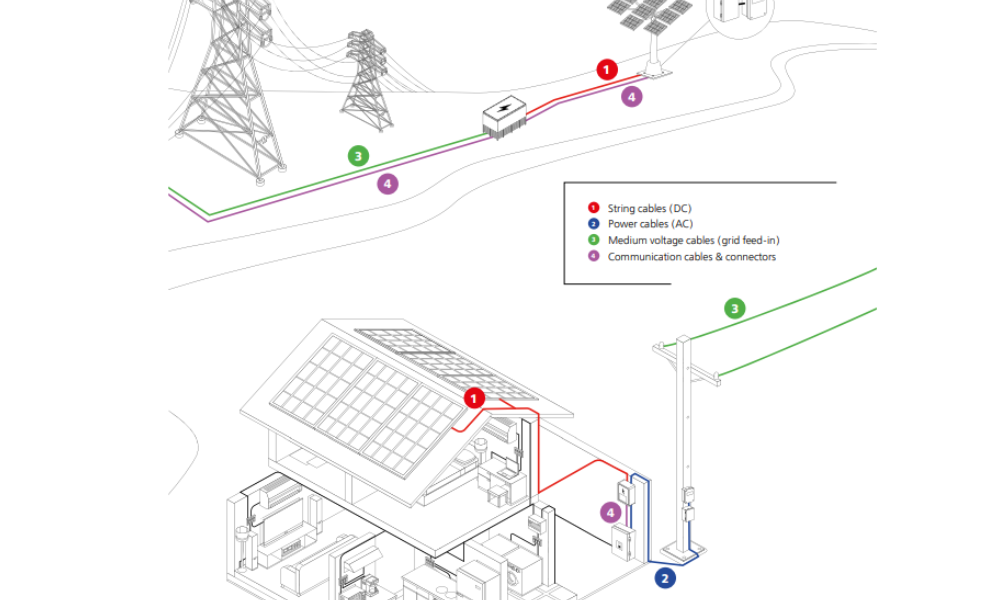

2. The roles of DC cables in photovoltaic systems

Solar cables serve as the physical connection between the various components of a solar power system. They carry the direct current (DC) generated by the solar panels to the inverter, where it is converted into alternating current (AC) for use in household appliances and the electrical grid.

2.1 Characteristics of DC cables

DC cables are the backbone of a solar power system, serving as the electrical pathway from the solar panels to the inverter for conversion into usable alternating current (AC). These cables are specifically designed to handle the high voltages and currents generated by solar photovoltaic arrays while minimizing energy loss and ensuring safe, reliable operation. Key characteristics of DC cables include:

- Voltage rating: DC cables are designed to handle the high voltages produced by solar photovoltaic arrays, typically ranging from 600 V to 1500 V or more.

- Current-carrying capacity: DC cables must conduct the high currents generated by solar panels under varying operating conditions. The current-carrying capacity depends on factors such as the cable's cross-sectional area, conductive material, and ambient temperature rating.

- Insulation requirements: DC cables must meet stringent insulation standards to ensure safe and reliable operation in harsh outdoor conditions, including exposure to sunlight, humidity, and temperature fluctuations. Common insulation materials include XLPE and ethylene propylene rubber (EPR), known for their excellent electrical and mechanical properties as well as resistance to environmental factors.

- Durability and weather resistance: DC cables are exposed to various environmental conditions such as sunlight, rain, wind, and extreme temperatures. As a result, they are designed to withstand these challenges while maintaining optimal performance and reliability over time.

2.2 Connecting DC cables and solar panels

Connectors, also known as junction boxes or combiner boxes, are crucial components that link solar panels and DC cables. They are designed to securely attach the DC cables to the solar panels while insulating and protecting against environmental hazards such as moisture, dust, and debris.

DC cables should be carefully routed from the solar panel connectors to the main junction box or combiner box, ensuring proper clearance and protection throughout the pathway. Cables must be secured using appropriate cable clips, brackets, or cable ties to prevent scratches or damage caused by wind, vibration, or thermal expansion. Additionally, it is important to avoid sharp bends, twists, or kinks in the cables, as these can increase resistance and reduce energy efficiency.

3. The roles of AC cables in photovoltaic systems

AC cables are used after the power has been converted to AC by the inverter, carrying the current to appliances in homes or businesses and sending any excess power back to the grid. These AC cables must adhere to strict standards for voltage rating, insulation, and safety to ensure seamless integration into existing electrical systems and compliance with regulations.

3.1 Characteristics of AC cables

- Voltage rating: AC solar cables are designed to conduct electricity at standard household voltages, typically ranging from 110V to 240V for residential applications, with higher voltages used in commercial and industrial settings. The voltage rating of an AC cable is determined by factors such as the size of the electrical load, transmission distance, and regulatory requirements for the electrical installation.

- Current carrying capacity: Like DC solar cables, AC solar cables must be capable of carrying the high currents produced by the solar inverter under various load conditions.

- Insulation requirements: Common insulation materials used in AC solar cables include PVC, XLPE, and ethylene propylene rubber (EPR). These materials offer excellent electrical and mechanical properties while providing resistance to environmental factors.

3.2 Connecting AC cables and solar power systems

The connection between the AC cables and the inverter typically occurs at the inverter's input and output terminals. The input terminals receive DC power from the solar panels, which is then converted to AC, while the output terminals deliver the converted AC power to electrical loads in the home or facility. In grid-tied systems, any excess power is returned to the grid.

The AC cable configuration can vary depending on the design and layout of the solar system, offering single-phase or three-phase connection options to accommodate different load requirements and power distribution needs. It is important to install appropriate overcurrent protection and grounding devices to ensure the safety and reliability of the electrical system.

4. HELUKABEL’s DC cables and solar cables for photovoltaic systems

HELUKABEL's product portfolio includes a wide range of DC cables, AC cables, and connectors, providing comprehensive solutions for the solar energy sector.

4.1 SOLARFLEX®-X H1Z2Z2-K DC cables

SOLARFLEX®-X H1Z2Z2-K is the typical DC cable of HELUKABEL, available in blue, red, and black colors. Technical data of this type of DC cable:

- Copper wire, finely stranded, class 5. Various cross-sections, ranging from 2.5 mm2 to 240 mm2.

- Operating temperature: -40°C to +90°C (fixed installation)

- Permissible operating temperature of the core: +120°C

- Nominal voltage: AC U0/U 1000/1000

- DC U0/U 1500/1500 V

- Test voltage: 6500 V

- Minimum bending radius: 5 times the diameter (fixed installation)

Besides, SOLARFLEX®-X H1Z2Z2-K DC cables are also available with the NTS upgraded version, equipped with rodent protection.

Datasheet of SOLARFLEX®-X H1Z2Z2-K NTS

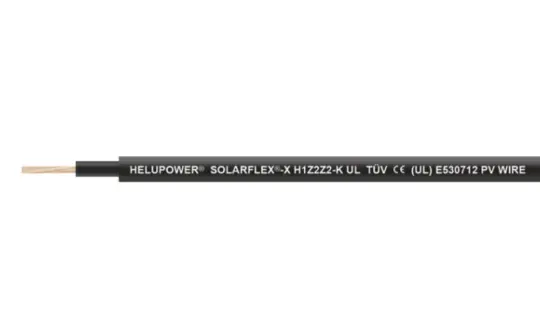

4.2 HELUPOWER® DC cables

HELUKABEL's solutions for photovoltaic systems are expanded with two new DC cables from the HELUPOWER® series: HELUPOWER® SOLARFLEX®-X PREMIUM , HELUPOWER® SOLARFLEX®-X H1Z2Z2-K UL .

| HELUPOWER® SOLARFLEX®-X H1Z2Z2-K UL | HELUPOWER® SOLARFLEX®-X PREMIUM | |

| Standard | DIN VDE 0283-618 / DIN EN 50618, IEC 62930, UL-Std. 4703 (PV Wire) | DIN VDE 0283-618 / DIN EN 50618, IEC 62930, TÜV Rheinland 2 PfG 2750 |

| Operating temperature | -40°C to +90°C (fixed installation) | -40°C to +90°C (fixed installation) |

| Nominal voltage | AC U0/U 1000/1000 V DC U0/U 1500/1500 V UL (PV) DC 2000 V | AC U0/U 1000/1000 V DC U0/U 1500/1500 V |

| Minimum bending radius | 5 times the diameter (fixed installation) | 5 times the diameter (fixed installation) |

| Applications | Suitable for system manufacturers who focus on exporting products to overseas markets, such as the US. Besides, this cable series is also suitable for exporting worldwide. | Suitable for use in floating photovoltaic systems or floating solar farms |

4.3 AC cable product lines

Some type of AC cables from HELUKABEL:

- HELUPOWER® 1000 RV-K cables are direct burial cables, XLPE insulation, temperature is up to 90° C.

- H07RN-F / 07RN-F cables are made of rubber, oil-resistant and weather-resistant.

- HELUPOWER® H07RN-F LS0H cables are oil-resistant, up to 100m depth in water.

4.4 DC connectors

The MC4 DC cable connectors and MC4-Evo2 cable connectors are integral components in completing HELUKABEL's solar power system solutions.

| MC4 | MC4 Evo2 | |

| Operating temperature | -40°C to +90°C | -40°C to +85°C |

| IP standard | IP67 | IP68 |

| Rated volatge | 1000 V (IEC) | 1500 V (IEC) |

| Rated current | 22A (2.5 mm²), 30A (4mm², 6mm²) | 39A (2.5 mm²), 45A (4 mm²), 53A (6 mm²), 69A (10 mm²) |

| Contact resistance | 0.35 mOhm | 0.20 mOhm |

If you still have any concerns or questions, don't hesitate to reach out to HELUKABEL Vietnam's engineering team promptly for detailed assistance.

HELUKABEL® Vietnam

905, Nguyen Kiem Street, Ward 3, Go Vap District, Ho Chi Minh City 700000, Vietnam

Tel. +84 28 77755578 | info@helukabel.com.vn | www.helukabel.com.vn