What are single core cables and their applications?

Single core cables have a simple structure and are widely used in both civil and industrial electricity. Let's learn basic information about single core cables through the following article!

1. What are single core cables?

Electric cables can be classified according to various criteria, such as the usage purposes (control cables, fire-resistant cables, data cables, etc.), insulation types (PVC, PUR, XLPE), and power sources (low voltage, medium voltage, high voltage cables). One of the simplest and most common ways to classify electric cables is based on the number of cores. Electric cables can be divided into single core cables and multi-core cables.

Single electric wires, or single core cables, consist of only one conductive core. This means that these wires are designed to provide a single path for transmitting electricity. The conductive material is placed in an insulating layer. The conductive core of a single electric wire is usually made of copper or aluminum.

2. Features of single core cables

Single core cables have characteristics that distinguish them from other types of electrical cables. These characteristics therefore make single core cables more suitable for certain applications than other types of electrical cables.

2.1 Single pathway design

The main characteristic of single core cables is that they provide a single path for the current to travel due to having only one conductive core. In contrast, multicore cables have multiple conductors within the same insulation. Therefore, single core cables are much simpler in design and construction than multicore cables.

2.2 Single core cables are highly flexible

Single core cables, having only one core, are more flexible and do not hinder twisting or use in continuously moving applications. However, it is important to note that these characteristics apply primarily to standard single core cables. Single core cables can come in various shapes, cross-sections, and thicknesses. A large-diameter cable can also be a single core cable, but it will lack the flexibility of a standard single core cable. Nonetheless, single core cables are generally more flexible than multicore cables of similar cross-section and construction.

2.3 Ability to withstand high voltages

A current-carrying wire generates a magnetic field around it, which can cause interference when interacting with surrounding signals. This magnetic field can affect the quality of power transmission, especially at high voltages.

Therefore, the construction of a single core, where the current passes through only one conductor, is less prone to electromagnetic interference compared to multicore cables. Single core cables are often chosen for high voltage applications because of their ability to withstand high voltages.

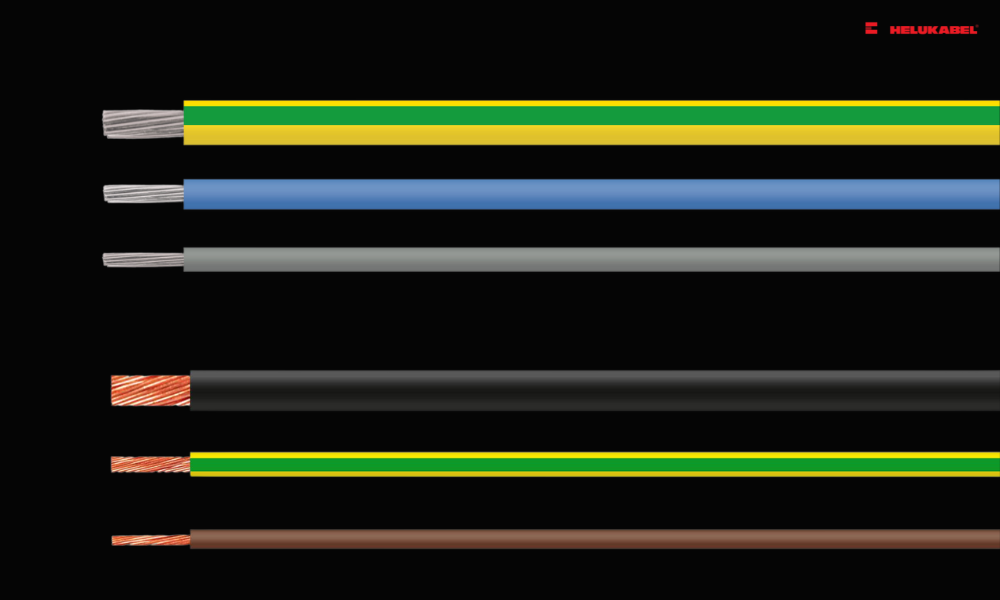

2.4 Color-based standardization

Single core cables are characterized by being color-coded according to standards. These standards ensure that the wires can be identified by casual observation. Furthermore, these codes reveal other information, such as intended use and rated voltage. For example, consider a technician constructing a system inside a factory. Such a system can be complex and require many different types of electrical cables and color coding helps identify the cables needed at a glance, ensuring a quick and safe process because the colors are easy to identify.

2.5 Single core cables are simple in design

Single core cables have certain advantages in manufacturing due to their simple design. These cables contain only a single conductor, unlike multicore cables, which have multiple conductive cores. The construction of single core cables is much simpler because there is no need to prevent individual wires from touching each other, which is essential in multicore cables to avoid short circuits. Consequently, the production and assembly process for multicore cables is much more complex. However, it is important to note that using higher quality materials and insulation can make both single core and multicore cables more expensive.

3. Applications of single core cables

Some of the common applications of single core cables are as follows:

- Power grids: Single core cables are the best choice for transmitting high voltage over long distances, making them ideal for power grids. Power grids are crucial for providing electricity to households, commercial centers, and other locations. Additionally, these grids include substations that convert high voltage into lower voltage suitable for households.

- Industries and factories: Machinery and systems used in industries and factories have a high demand for electricity. Single core cables can be widely used in these environments for various purposes, such as connecting systems, control panels, machinery, and equipment. Moreover, they are durable and flexible, suitable for long-term use and installation in locations with many bends, corners, and twists.

- Railway systems, HVAC systems in commercial buildings, apartment complexes, and homes.

- Telecommunications networks: Telecommunications networks consist of towers that transmit signals and data over long distances, allowing remote locations to communicate with each other. Single core cables play an important role in providing power to these towers and ensuring the network operates efficiently. Additionally, single core cables reduce electromagnetic interference, ensuring that signal transmission is not obstructed.

4. Classifications of single core cables

Some common ways to classify single core cables are as follows:

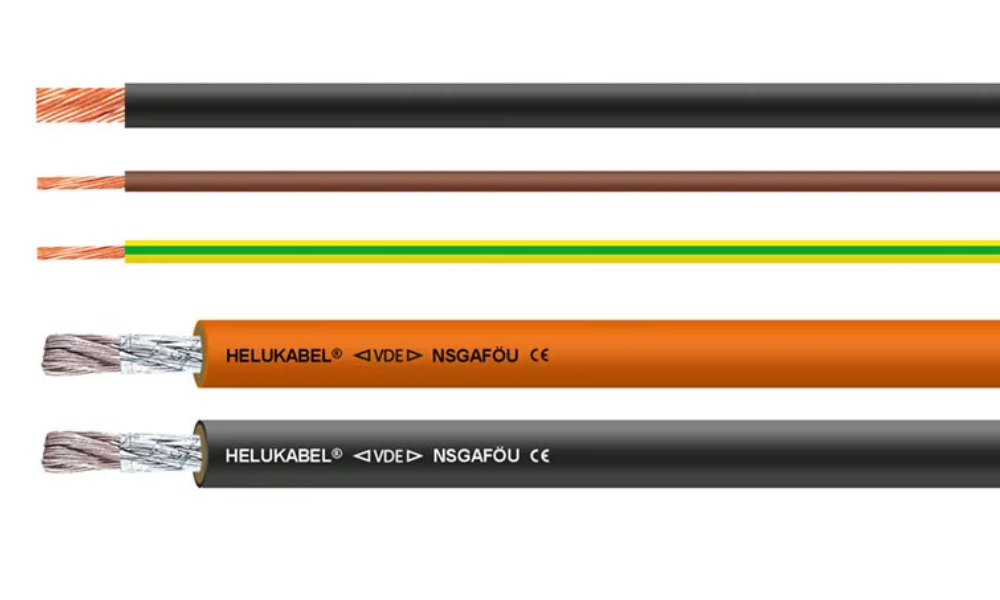

4.1 Solid single core cables

A solid single core wire, or solid single core cable, is a type of cable that has a single conductor made of solid metal, usually copper or aluminum, surrounded by insulation. The cable is then encased in a single sheath made of rubber, PVC, or other materials.

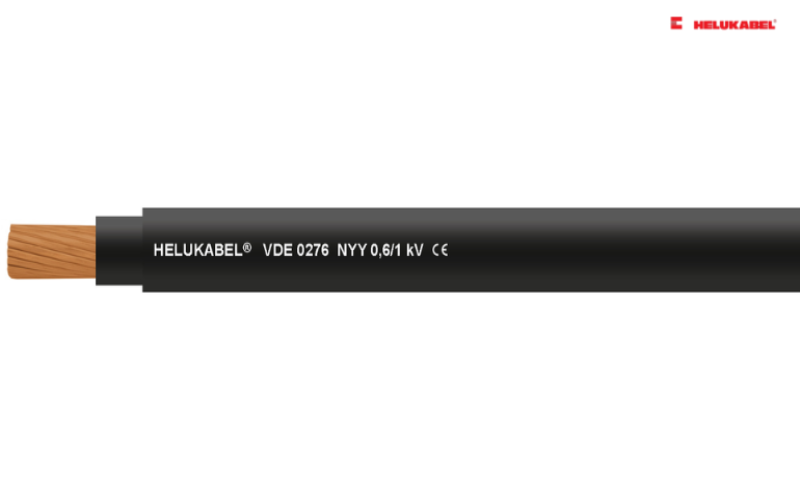

Some solid single core cables from HELUKABEL:

- H05V-U in accordance with DIN VDE 0285-525-2-31 / DIN EN 50525-2-31 is used for installation in electrical conduits, on and under plaster, but only for signal and control circuits. Suitable for protected and fixed installation in appliances and luminaires.

- NYY / (N)YY with rated voltage U0/U 0,6/1 kV is used for power supply installed outdoors, underground, underwater, in concrete, indoors, in cable ducts, power plants, for industry and distribution boards as well as in subscriber networks where there is no possibility of mechanical damage.

- SiF/GL, SiD, SiD/GL are single core cables with high temperature resistance range, up to +220°C, mainly used in steel manufacturing industries, in the aviation industry as well as in shipbuilding, cement, glass and ceramics plants.

4.2 Soft single core cables

Different from solid single core cables, a soft single core wire has a conductive core consisting of many small fibers, suitable for civil applications. Some typical applications include wires connecting household appliances, electrical control cabinets, distribution boxes and wires connecting low-voltage electrical equipment, which can be used to transmit electric power, electrical control signals and switching signals.

Here are some typical single core cable lines of HELUKABEL:

- H05 V-K and H07 V-K single core cables are diverse in cross-section and color, often used for electrical systems in buildings and commercial centers.

- Single core cables H07Z-K / 07Z-K are halogen-free, suitable for applications requiring low smoke and corrosive gas development in the event of a fire.

- NSGAFÖU 1.8/3 kV single core rubber-sheathed power cables for railway and bus transport, as well as in dry rooms. The standard permissible installation types are in conduits, closed ducts, for connecting moving parts, wiring devices and cable bundles. Not for use in cable ladders and cable trays.

4.3 Drag chain compatible single core cables

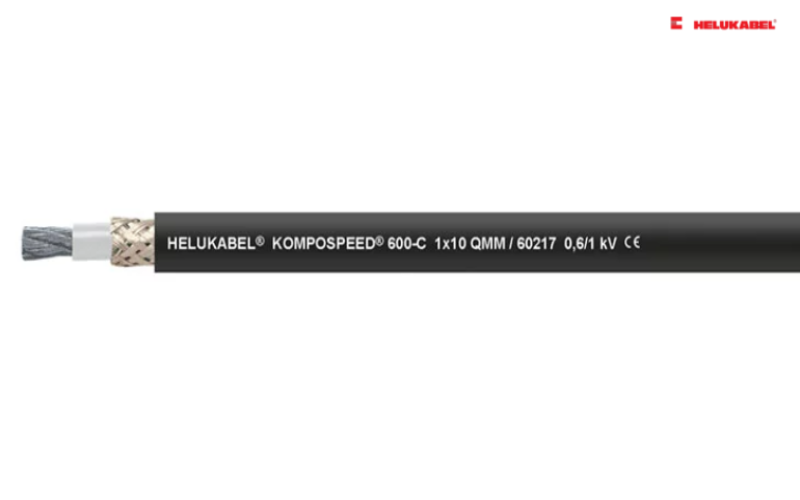

Some single core cables with enhanced mechanical properties, suitable for continuous moving applications such as drag chains:

- MULTISPEED®-600-C-PUR-J / MULTISPEED®-600-C-PUR-O are resistant to interference, suitable for installation in long distance and high-speed applications in dry, humid and wet environments as well as for outdoor use.

- Single 602-RC-J / Single 602-RC-O is a line of oil-resistant, UV-resistant cables, mainly designed for export-oriented machinery manufacturers for flexible applications in machinery, machine tools, robotic engineering, for automatic moving machine parts.

- KOMPOSPEED® 600/600-C 0.6/1kV is a special single core cable used for fixed flexible applications in machinery, machine tools, composting equipment and wastewater treatment plants, livestock barns and greenhouses and used for fixed flexible applications for moving and multi-shift automatic machinery components as well as outdoors.

4.4 Other types of single core cables

Besides, single core cables are also used in other industries such as solar energy or wind energy:

- HELUPOWER® SOLARFLEX®-X PREMIUM is water-resistant according to TÜV Rheinland 2 PfG 2750, used for solar farms and floating solar farms.

- HELUWIND® WK POWERLINE ALU ROBUST 0.6/1 kV has high flexibility and low dead weight, extreme resistance to abrasion and mechanical stress. Therefore, this single wire product is used in many fields of energy and plant engineering.

- H01N2-E single core cable is designed to transmit current between welding transformer and electrode. This cable series is used in several industries such as automotive industry, shipbuilding, conveyor and assembly lines, etc.

If you still have any concerns or questions, don't hesitate to reach out to HELUKABEL Vietnam's engineering team promptly for detailed assistance.

905, Nguyen Kiem Street, Ward 3, Go Vap District, Ho Chi Minh City 700000, Vietnam

Tel. +84 28 77755578 | info@helukabel.com.vn | www.helukabel.com.vn