What are PUR control cables and their applications?

Selecting cable sheaths is pivotal to the durability, safety, and performance of electrical systems. This article aims to explore the features and applications of PUR control cables.

1. A glance at PUR control cables

1.1 How important is cable sheath?

The sheath is the outer-most layer of cables. It is an enclosed wrapping that is extruded onto the cable or wire using one of several extrusion methods. The sheath protects the cable cores and other structural components from external factors such as temperature, moisture, chemical, and mechanical influences. It also secures the shape and form of the stranded cores, as well as the screening, if present, which minimizes disruptions in the electromagnetic compatibility (EMC) of the cable. The sheath, therefore, not only correlates with the durability of the cables, but is also important in ensuring the consistent transmission of energy, signals, or data within the cables.

PUR and PVC are a more prevalent type of cable sheath. Optically, there is no difference between these materials. However, to a greater or lesser extent, they exhibit unique properties, which are best suited to certain applications. Other materials can also be used as sheath material, including commercial rubber, thermoplastic elastomers (TPE), and special compound plastics.

>>See more: Choosing insulating sheaths for cables

1.2 What are PUR materials?

The term “polyurethane” (or PUR) signifies a group of plastics which were developed at the end of the 1930s. It is produced through a chemical process called polyaddition. The raw base material is typically petroleum, however raw plant materials such as potatoes, corn, or sugar beets can be used in its production as well. PUR are thermoplastic elastomers. This means that they are flexible under heat but can return to their original form when the heat is removed. In standards and article descriptions, PUR is given the label 11Y.

1.3 Characteristics of PUR control cables

PUR has especially good mechanical properties. The material is extremely abrasion, cut, and tear resistant, and remains highly flexible even at low temperatures. This makes PUR especially suited for applications subjected to dynamic movements and bending requirements, such as in drag chains. Cables with PUR sheaths have no problem enduring millions of bending cycles or strong torsion forces in robotics applications. PUR is also highly resistant to oils, solvents, and UV radiation. Furthermore, depending on the material’s composition, it is halogen-free and flame-retardant, which are important criteria for cables with UL approvals.

>>See more: Drag chain cable - TOPSERV PUR control cables

1.4 Applications of PUR control cables

PUR control cables are characterized by outstanding mechanical and chemical characteristics, making it suitable for various applications:

- Industrial automation: The abrasion-, cut-, and tear-resistant characteristics render PUR control cables reasonable for harsh environmental conditions as well as automated systems that require continuous and repetitive movements.

- Renewable energy: Owing to their capabilities to withstand harsh conditions and UV rays, PUR control cables are ideal for use in wind turbines and solar panels.

- Transportation: PUR cables are widely used in transportation applications, such as autos, trains, buses and aircraft, because of their flexibility and durability, making them viable for constant vibration and movements.

- Communications: PUR control cables can also be used for sound and lighting systems.

>>See more: Halogen-free control cables for outdoor uses

2. A comparison between PUR and PVC control cables

| PUR | PVC | |

| VDE label | 11Y | Y |

| Temperature resistance | -55°C to +90°C | -30°C to +80°C |

| Halogen-free | Possible* | No |

| Mechanical durability | Very high | High |

| Abrasion resistance | Very high | Medium |

| Flexibility | Medium | High |

| Oil resistance | Very high | Medium |

| UV resistance | Very high | Possible* |

| Resistance to cleaning agents | High | Very high |

| Suitable for wet areas | Good | Very good |

| Material costs | High | Low |

*Can be improved through the use of different material mixtures

PVC control cables are highly flexible and suitable for a variety of applications by altering their component ratios. The mechanical loading capacity is not as high as PUR control cables, yet they are more economical; PUR control cables, on average, are four times more expensive. In addition, PVC control cables are odorless and resistant to water, acids, and cleaning agents, making them ideal for use in the food industry or humid environments. However, PVC control cables contain halogen, which makes them unsuitable for certain indoor applications.

PVC control cables are more favorable for general applications, especially when cost is a priority. In contrast, PUR control cables are better suited for more demanding industrial applications where resistance to harsh environments and a longer service life are important requirements.

3. HELUKABEL’s PUR control cables

HELUKABEL’s portfolio encompasses various kinds of PUR control cables tailored to customer needs. Some of the typical ones include:

| Temperature range (flexing) | Temperature range (Fixed) | Nominal voltage U0/U | Bending radius (Fixed) x Ø | Bending radius (Flexing) x Ø | Halogen-free | Resistance to UV | Drag chain compatible cable | |

| PURö-JZ / PURö-OZ | -20°C to +80°C | -40°C to +80°C | 300/500 V | 7.5x | 4x | x | ||

| PURö-JZ-HF | -20°C to +80°C | -40°C to +80°C | 300/500 V | 7.5x | 4x | x | x | x |

| JZ-500-PUR / OZ-500-PUR | -15°C to +80°C | -40°C to +80°C | 300/500 V | 7.5x | 4x | x | ||

| MULTIFLEX 512®-PUR | -30°C to +80°C | -40°C to +80°C | 300/500 V | 5x | 3x | x | x | x |

| MULTISPEED® 500-C-PUR | -30°C to +80°C | -40°C to +80°C | 300/500 V | 7.5x | 4x | x | x | x |

| TOPFLEX® 611-PUR | -30°C to +80°C | -40°C to +80°C | 0.6/1kV | 7.5x | 4x | x | x | x |

| TOPSERV® 110 / 120 | -30°C to +80°C | -40°C to +80°C | 0.6/1kV | 7.5x | 4x | x | x | x |

In this article, outstanding characteristics of PURö-JZ-HF / PURö-J-HF / PURö-OZ-HF control cables will be discussed.

4. Top 4 outstanding features of PURö-JZ-HF control cables

PURö-JZ-HF / PURö-J-HF / PURö-OZ-HF is drag chain compatible cables, possessing the following structures:

- Copper wire bare, extra finely stranded acc. to DIN VDE 0295 Class 6 / IEC 60228 Class 6.

- Core insulation: oil-resistant PVC in alignment with DIN VDE 0207- 363-3 / DIN EN 50363-3 (compound type TI2).

- Core identification acc. to DIN VDE 0293-334, black cores with consecutive labeling in white digits.

- G = with protective conductor GN-YE, in the outer layer, x = without protective conductor (OZ).

- Cores stranded in layers with optimally matched lay lengths.

- Outer sheath: Special grade of full polyurethane acc. to DIN VDE 0207-363-10-2 / DIN EN 50363-10-2 (compound type TMPU).

- Sheath colour: grey (RAL 7001).

Data sheet of PURö-JZ-HF / PURö-J-HF / PURö-OZ-HF

Outstanding characteristics of PURö-JZ-HF control cables:

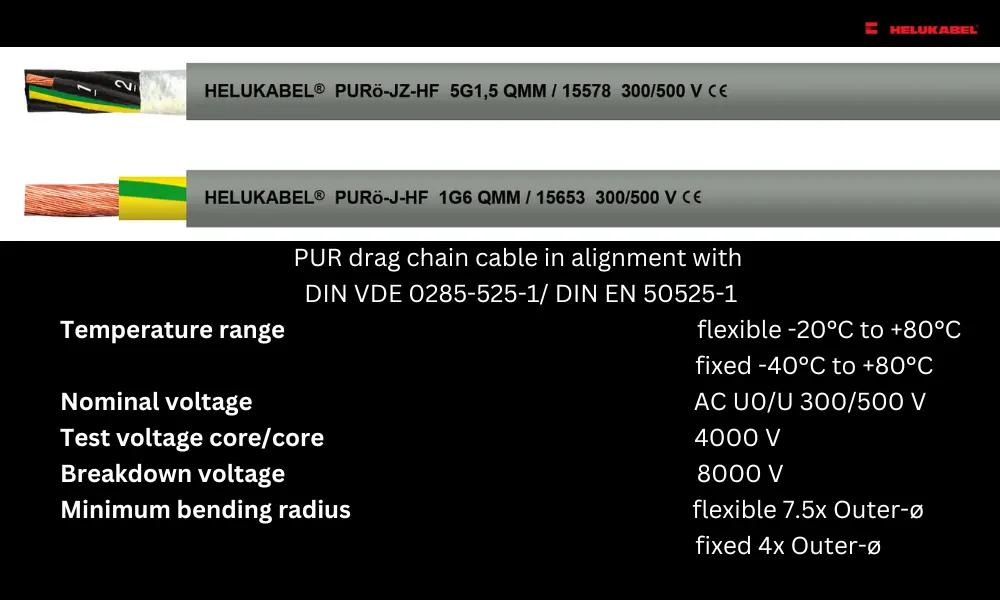

4.1 Operating temperature up to 80 °C

PURö-JZ-HF can function well within a huge temperature spectrum, ranging from -20°C to +80°C (when flexing) and -40°C to +80°C (fixed installations). Thus, these cables are compatible with many environmental conditions, including outdoor uses.

4.2 Resistant to demanding environments

PURö-JZ-HF control cables comply with different standards:

- Oil-resistant acc. to DIN VDE 0473-811-404 / DIN EN 60811-404 / IEC 60811-404.

- UV-resistant acc. to DIN EN ISO 4892-2.

- Weather-resistant acc. to DIN EN ISO 4892-2

PURö-JZ-HF control cables are extremely robust despite harsh environmental conditions. Due to its resistance to mineral oils, notably against coolant emulsions, it is suited for use in particularly critical locations in machine, tool and plant construction, rolling mills and steelworks.

4.3 Compatible with drag chains

This is an extremely sturdy cable line with high durability, cut and tear resistance, abrasion resistance and notch-tensile strength properties. Furthermore, the small bending tempering radius (4 times the core diameter for fixed installations and 7.5 times that for flexing’s) makes PURö-JZ-HF an excellent choice for continuous moving applications such as drag chains.

4.4 PURö-JZ-HF control cables come in different cores and cross-sections

Another outstanding feature of PURö-JZ-HF control cables is the diversity of cores and cross-sections. Users can opt for single core or multicores (up to 65 cores) PURö-JZ-HF control cables; cross-sections vary between 0,5mm2 and 95mm2.

>>See more: Why cross-sections are important?

If you still have any concerns or questions, don't hesitate to reach out to HELUKABEL Vietnam's engineering team promptly for detailed assistance.

HELUKABEL® Vietnam

905, Nguyen Kiem Street, Ward 3, Go Vap District, Ho Chi Minh City 700000, Vietnam

Tel. +84 28 77755578 | info@helukabel.com.vn | www.helukabel.com.vn