Converting gas into electricity… and back again!

Bavarian start-up Reverion outfits their fuel cell plants with HELUKABEL cables

Biogas plays an important role in the world of renewable energies. However, there is still considerable potential yet to be harnessed in its production and usage. It is the goal of the start-up Reverion to better exploit this resource through innovative, container-based power plants. These Bavarian visionaries rely on high-quality HELUKABEL cables to connect the electronic components of their fuel cell systems.

The production and usage of biogas play an important role in the global transition to renewable energies. In Germany alone, around 10,000 biogas production facilities are currently in operation, which produce biogas by fermenting livestock manure and other forms of biomass. The biogas produced in this way is primarily transformed into electricity, typically in cogeneration plants with combustion engines. More than 30 terawatt hours of electricity is produced from biogas per year in Germany, which equates to approx. 18% of the total energy produced domestically from renewable sources.

The advantage biogas has over other renewable energy sources is that its usage is unaffected by weather and sunlight. This means that it continues to be useful even when wind and solar plants fall behind in energy production. Biogas technology also has its drawbacks. Most facilities are only roughly 40% efficient, resulting in most of the energy being lost in production. The amount of CO2 released by burning biogases is relatively low when compared to electricity produced by burning coal or natural gas, but still considerably higher than wind, hydro, and solar energy.

Increased efficiency and a reduced carbon footprint

The system can be switched to an electrolysis mode, which allows electrical energy to be used to produce hydrogen and methane.

“Biogas has a lot of potential, it just needs to be better utilized,” says Lukas Berneiser, head of electronics at Reverion GmbH. With roots in the Technical University of Munich, the Bavarian start-up has made it their goal to improve the efficiency of biogas production. Reverion has developed and patented a revolutionary, container-based power plant system that is capable of electrochemically converting biogas and hydrogen into electricity with 80% efficiency. The carbon dioxide produced during this process is separated and then sequestered, which, for the first time, allows for cost-efficient negative CO2 emissions.

“Our systems are especially attractive for agricultural and industrial businesses that have their own biogas production facilities,” explains Berneiser. “This is because with our technology, they could produce twice as much energy from the same amount of biogas.” Their system comes with another significant advantage: It’s reversable. “This means that, in less than a minute, the system can be switched to an electrolysis mode, which allows excess energy from solar and wind power stations to be used to produce hydrogen and methane,” says Berneiser. Through this, energy can temporarily be stored as gas, and then converted back into electricity or thermal energy when needed.

Energy storage and customer demand

Reverion’s electrical equipment relies on the expertise of, among others, HELUKABEL.

Central to the Reverion system is a framework of solid oxide fuel cells, called the skid. To produce electricity, purified biogas is injected into the cells where it is partially oxidized by ambient air. This produces electrical energy, which is picked up by the grid. The pure CO2 byproduct is separated and sequestered and can then be utilized in a number of technical or industrial applications. The electrolysis mode essentially goes through this process in reverse. The fuel cells use electrical energy to produce pure hydrogen, which can be stored or further converted into methane using CO2. Methane has similar characteristics and applications as natural gas. Berneiser is convinced that, “this system is the solution to multiple challenges, especially those of efficiently storing and utilizing renewable energy.”

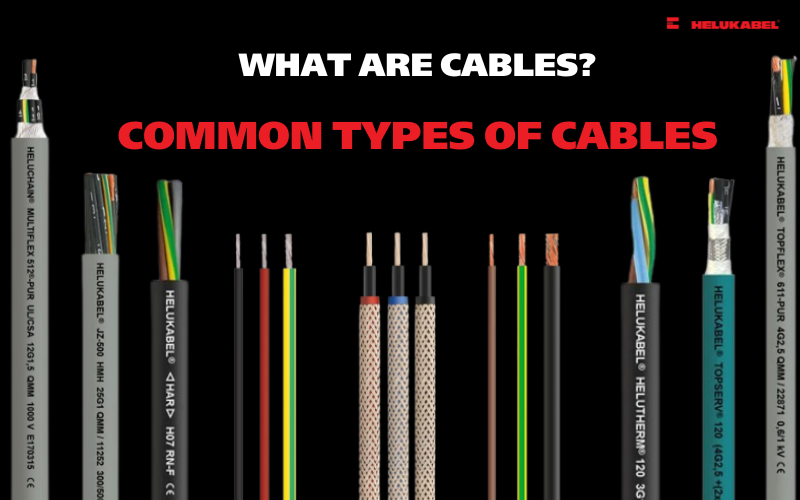

Reverion’s electrical equipment relies on the expertise of, among others, HELUKABEL, who supplies the cables that connect the fuel cells, power inverters, sensors, and actuators, as well as the wiring for the internal control panels. Data cables are also used for communication between the skids over an Ethercat network, as well as hybrid lines which feed and monitor various motors. “The built-in cables need to be able to endure voltages as high as 1,500 volts and temperatures up to 300 degrees Celsius,” explains Berneiser. “For us, it is of equal importance that all of our required components are of the highest quality and are reliably available.”

Competent advice and a vast portfolio

After many recommendations, the Reverion team came in contact with HELUKABEL and regional sales manager Philipp Walter. “Our conversations were pleasant, and Mr. Walter was friendly and competent,” remembers Berneiser. The two worked together to find the ideal cable for each application. “We’re supplying Reverion, for example, with solar cables from the SOLARFLEX series, weather-resistant H07RN-F cables, TOPSERV hybrid cables, and H07V-K single-core wires. Accessories such as cable glands from the HELUTOP product line round out the shipment,” explains Walter. In high-temperature areas, such as near the fuel cells, Reverion utilizes especially heat-resistant HELUTHERM 400 nickel cables, which are capable of withstanding temperatures up to 400 degrees Celsius. With a product range consisting of over 33,000 items, HELUKABEL is able to find a fitting solution for any application, regardless of how challenging, and it was this ingenuity that won over the leadership at the Bavarian start-up.

The first Reverion plant with an electrical output of 100 kilowatts has been undergoing a pilot run since October 2023, and serial production is planned for 2024 and 2025. With this, the containers will be able to be distributed throughout Germany, as well as to neighbouring countries. “If the cables in our pre-series products prove themselves in practice, then we plan to continue placing our trust in HELUKABEL for our serial production,” states Berneiser. “HELUKABEL has proven to be a reliable partner and has provided us with the exact cables needed to fulfil our particular demands. This has drastically increased the speed at which our innovative fuel cell plants are approaching serial production. We look forward to continuing to work together in the future!”

You can also find this and many other exciting articles in the current issue #15 of our customer magazine POWER. Read it now!